What happens when your LED strip lights encounter water? Rest assured, you’ve come to the right place. Our comprehensive guide delves deep into the world of LED strip lighting and water interaction, providing you with all the knowledge and solutions you need to navigate this issue confidently.

When LED strip lights get wet, they risk short circuits, corrosion, and potentially complete failure. The extent of damage largely depends on their water resistance rating and how much moisture they’re exposed to.

Dive deeper into our guide to discover the nuances of water resistance in LED strip lights and uncover valuable strategies for prevention, maintenance, and repair. Your journey to mastering the resilience of LED lighting in the face of moisture starts here.

Understanding Water Resistance in LED Strip Lights

When venturing into the world of LED strip lights, a fundamental aspect to grasp is their ability to resist water. This characteristic is not just a matter of convenience but a crucial factor that can determine the longevity and safety of the lighting in various environments. Let’s dive into the intricacies of this feature.

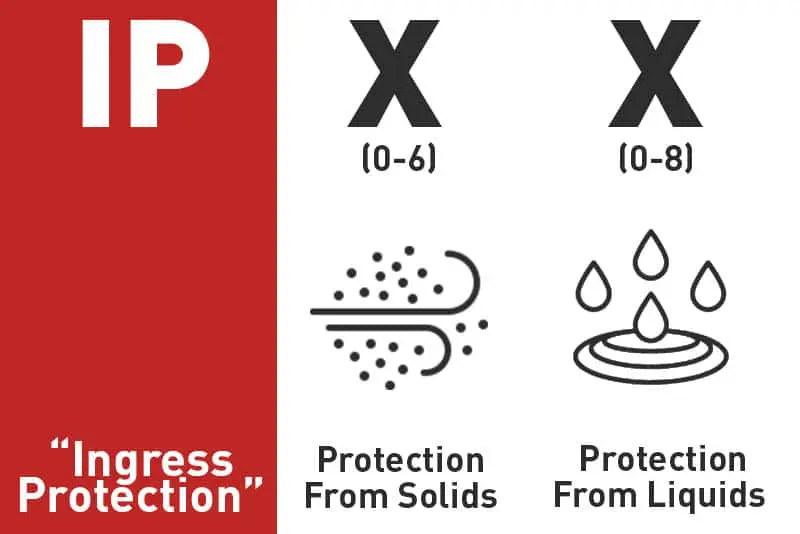

Exploring Different IP Ratings

The Ingress Protection (IP) rating system is a universally recognized scale that measures the degree of protection an electrical enclosure, like an LED strip light, offers against elements such as dust and moisture. Ranging from IP20, which offers no water resistance, to IP68, capable of withstanding complete and prolonged submersion, these ratings guide users in choosing the right LED strip for their specific needs. For instance, an LED strip with an IP65 rating is generally considered safe for use in kitchens or bathrooms, where exposure to moisture is frequent but not extreme. Meanwhile, IP68-rated strips are ideal for outdoor settings or even underwater applications, like in pools or fountains.

Effects of Water Exposure

The consequences of water exposure on LED strips can range from mildly inconvenient to downright hazardous. At the lower end of the scale, moisture can cause a drop in lighting quality or erratic lighting behavior. More seriously, water ingress can lead to electrical shorts, posing a fire hazard or causing permanent damage to the LED circuitry. Over time, consistent exposure to moisture, especially in non-water-resistant models, can accelerate the corrosion of metal components, leading to irreversible damage and failure of the entire lighting system.

Immediate Actions Post-Water Exposure

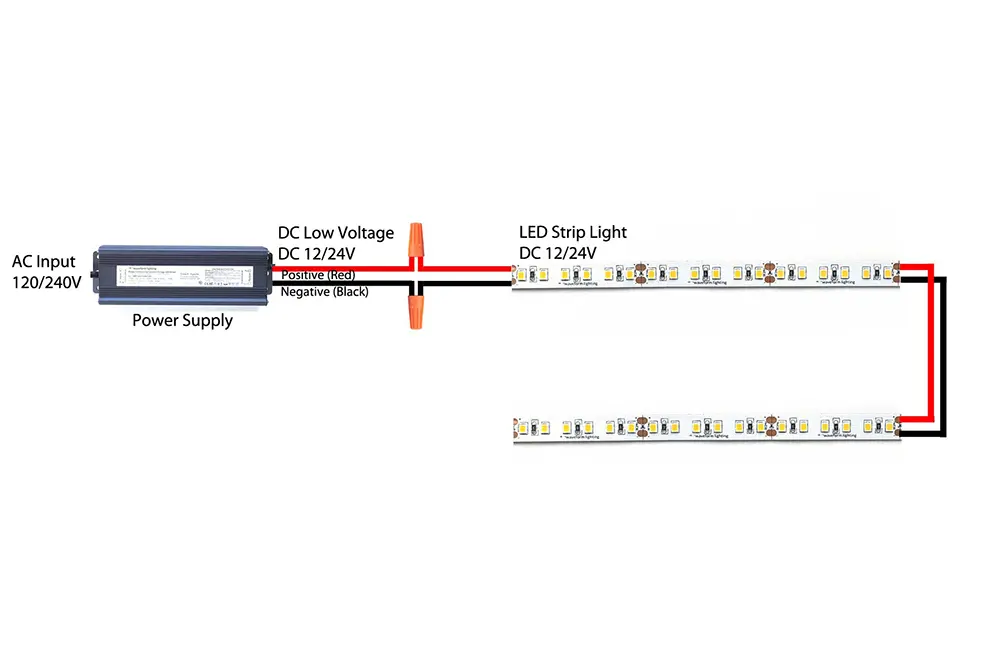

In scenarios where an LED strip encounters unexpected water exposure, immediate action is crucial. First and foremost, ensure safety by turning off the power supply to the affected area to eliminate any risk of electrical shock or short circuit. Then, carefully remove the LED strip from the moist environment and dry it thoroughly, preferably in a well-ventilated area or with the aid of a gentle, dry heat source. It’s essential to check all connections and endpoints for signs of water ingress, as these are often the first points of failure. If the strip is extensively damaged or if you’re unsure about its condition, it’s wise to consult with a professional before attempting to reconnect or reuse the strip. This proactive approach not only safeguards your investment in LED lighting but also ensures the ongoing safety and functionality of the installation.

Preventing Water Damage to LED Strips

Navigating the world of LED strip lighting can be tricky, especially when considering their use in areas prone to moisture. The key to a successful and long-lasting installation lies in three main areas: proper installation, selecting the right type of LED strips, and regular maintenance.

Installation Tips for Moisture Prevention

When installing LED strips in areas like bathrooms or kitchens, where moisture is a common occurrence, it’s crucial to consider both the location and the method of installation. Here are a few tips:

- Elevate Placement: Keep the LED strips away from direct contact with water. For instance, install them under cabinets or overhangs where they’re less likely to get splashed.

- Use Waterproof Channels: Encasing LED strips in waterproof channels not only protects them from water but also adds to the aesthetic appeal.

- Seal Connections: Ensure that all connections and endpoints are well-sealed with appropriate waterproof materials. Silicone sealants are often a good choice.

Selecting Suitable LED Strips for Damp Environments

Choosing the right LED strips for moisture-rich environments involves understanding the different IP ratings:

- IP65 Rated LED Strips: Ideal for general use in kitchens and bathrooms, these strips are protected against water jets and condensation.

- IP67 and IP68-rated LED Strips: These are suitable for outdoor settings or areas with high exposure to water. IP68 strips can even be submerged, making them perfect for pools or water features.

Remember, the higher the IP rating, the better the protection against water, but also consider the flexibility and the brightness of the strip.

Maintenance for Longevity

Regular maintenance is key to ensuring the longevity of your LED strips in damp environments:

- Routine Cleaning: Dust and debris can accumulate on the strips and in the crevices, potentially trapping moisture. Gentle cleaning with a dry cloth can prevent this.

- Check for Water Ingress: Periodically inspect your LED strips for signs of moisture penetration, especially after heavy rain if they are installed outdoors.

- Monitor for Corrosion: Pay attention to any signs of corrosion in the connectors or the strips themselves, as this could be a sign of water damage.

Resolving Water-Related Problems in LED Strips

Addressing water-related issues in LED strips begins with early detection and understanding of the extent of the damage. When you notice signs of water damage, such as dimming, flickering, or a complete outage, it’s time to investigate. Firstly, assess the IP rating of your LED strip and its installation area to determine the vulnerability to water exposure. This initial step is crucial in deciding the next course of action.

In cases where the damage is minimal, or the LED strip is designed to withstand some level of moisture (like IP65 rated), you can perform DIY repairs. This could involve drying out the strips, checking and tightening connections, or replacing small parts. However, if the strip is heavily water-damaged or if you’re uncertain about handling electrical components, it’s safer to seek professional assistance. A skilled technician can identify issues that might not be obvious at first glance and can ensure that the repairs meet safety standards.

When undertaking any repair work, whether DIY or professional, safety and compliance with electrical standards must be balanced; always ensure that the power supply is turned off before attempting any repairs, and use tools and materials that are appropriate for electrical work. Adhering to these safety standards not only protects you but also ensures the longevity and proper functioning of the LED strips post-repair.

Advances in Water-Resistant LED Strip Technology

The LED strip lighting industry is witnessing a thrilling era of innovation, especially in enhancing their resilience to water. This journey of technological advancement is shaping a new future for LED strips, making them more versatile and durable in various environments.

Innovative Materials and Enhanced Protection

One of the key advancements in this field is the development of advanced silicone coatings. Unlike traditional coatings, these silicone-based solutions offer a much higher level of protection against moisture and humidity. They effectively seal the delicate components of the LED strips, extending their lifespan even in challenging conditions like heavy rainfall or high humidity areas.

Another significant improvement is in the encapsulation techniques used in LED strip manufacturing. Modern encapsulation methods are more refined, providing a tighter seal around the LED components. This not only protects against water ingress but also helps in preventing damage from physical impact or abrasion.

Emerging Technologies and Future Possibilities

Nanocoating technology is a cutting-edge development that’s starting to make waves in the industry. This innovative approach involves applying a nanoscale layer of protective material over the LED strips. What’s exciting about this technology is its potential to offer self-cleaning properties. Imagine LED strips that can resist water and also repel dust and dirt, significantly reducing the need for maintenance.

As we look forward, the potential advancements in LED strip technology are boundless. The focus is shifting towards creating water-resistant coatings that do not compromise the LED’s brightness or flexibility. This balance is crucial for maintaining the aesthetic appeal of LED strips while enhancing their practicality.

Revolutionizing LED Applications

The advancements in water-resistant technology are paving the way for more innovative uses of LED strips. We’re likely to see an increase in their application in outdoor settings, aquatic environments, and even in areas with extreme weather conditions. This will not only expand the creative possibilities for architectural and landscape design but also increase the functional applications of LED lighting in everyday life.

Case Studies and Real-World Applications

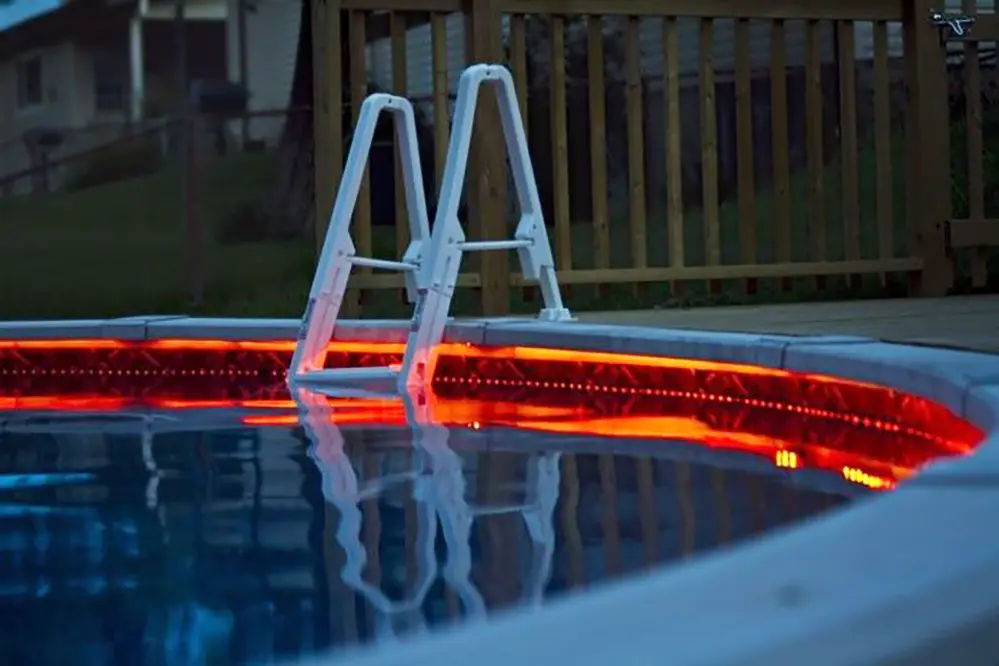

Real-world applications of water-resistant LED strips provide valuable insights into their practicality and resilience—for instance, a recent project involved installing LED strips in an outdoor garden. The LED strips used were IP67-rated, meaning they were completely protected against dust and capable of withstanding temporary submersion in water. Despite heavy rains and occasional garden watering, the LED strips continued to function flawlessly, showcasing their durability.

Another case study involves the use of LED strips in a commercial kitchen. Here, IP65-rated LED strips were installed under the cabinets for task lighting. The environment was prone to steam and occasional splashes of water. The LED strips not only provided excellent illumination but also withstood the humid conditions without any signs of damage or reduced functionality.

However, not all instances are successful. A notable example is the installation of non-waterproof LED strips in a bathroom. The constant exposure to steam and moisture led to the rapid degradation of the strips, resulting in flickering lights and, eventually, complete failure. This case highlights the importance of choosing the right type of LED strip for specific environments and serves as a learning opportunity for future installations.

Through these real-world examples, we gain a comprehensive understanding of the capabilities and limitations of water-resistant LED strip technology. They serve as a testament to the importance of selecting the appropriate IP rating for the intended use and environment, ensuring the longevity and effectiveness of LED strip lighting solutions.

FAQs on LED Strip Lights and Water Exposure

This FAQ section addresses common queries about LED strips in wet conditions. From their durability to maintenance tips, this part aims to clarify any lingering doubts.

Q: Can LED strip lights be used safely in high-humidity areas like bathrooms?

A: Absolutely! LED strip lights with a suitable IP rating (like IP65 or higher) are designed to withstand high-humidity environments. Just ensure they’re correctly installed and not directly exposed to water jets.

Q: How do I protect my LED strip lights from water damage outdoors?

A: Opt for LED strip lights with a high IP rating (IP65 or above) for outdoor use. Additionally, using a silicone sealant on connections and ensuring proper enclosures for power supplies can significantly enhance their water resistance.

Q: What immediate steps should I take if my LED strip lights get wet?

A: First, turn off the power to prevent electrical hazards. Dry the lights thoroughly and check for any visible damage. If you need more clarification, consult a professional electrician for safety.

Q: Are there waterproof options for LED strip lights in kitchens?

A: Yes, LED strip lights with an IP65 rating are ideal for kitchen use, as they can resist moisture and occasional splashes, making them perfect for under-cabinet lighting.

Q: Can exposure to rain shorten the lifespan of outdoor LED strip lights?

A: While high-rated IP65 LED lights are resistant to rain, continuous exposure to harsh weather can shorten their lifespan. Regular maintenance and proper installation can help mitigate this.

Q: Do LED strip lights require special maintenance in damp environments?

A: Regular maintenance, like gentle cleaning and checking for water ingress, is recommended. Ensure that the LED strips are dry and free from any condensation buildup.

Q: How does water resistance vary among different LED strip lights?

A: Water resistance in LED strip lights varies based on their IP rating. For example, IP65-rated strips can handle splashes and jets of water, while IP67 can withstand temporary immersion.

Q: What should I look for when buying LED strip lights for an outdoor pool area?

A: Look for LED strip lights with a high IP rating (IP67 or IP68), ensuring they are waterproof and suitable for outdoor conditions, particularly if they’re near water.

Q: Can condensation affect the performance of LED strip lights?

A: Yes, condensation can lead to moisture buildup inside the strip, potentially causing damage. Choose higher IP-rated LED strips for areas prone to condensation.

Q: Are there LED strip lights that can be submerged in water for decorative purposes?

A: LED strips with an IP68 rating are suitable for submersion, making them ideal for underwater lighting in fountains, pools, and other decorative water features.

Conclusion

The guide concludes by summarizing the key points about managing LED strip lights in wet conditions. For the importance of understanding their water resistance capabilities, the conclusion reiterates the need for careful selection, installation, and maintenance for optimal use and longevity.

In conclusion, understanding the dynamics between LED strip lights and water exposure is pivotal for ensuring their effective and safe use in various environments. As we’ve explored in this guide, the right selection, installation, and maintenance of these lights are key to their longevity and performance. If you’re looking for top-tier LED lighting solutions, look no further than Unitop, one of China’s premier manufacturers of LED strip lights and LED neon flex. With a deep commitment to quality and innovation, Unitop stands at the forefront of the LED industry, offering products that blend advanced technology with durability. For any further inquiries or specific requirements, don’t hesitate to contact Unitop immediately. Trust in our expertise to illuminate your spaces with efficiency, style, and reliability.

Tom is now the Sales Manager of Unitop (China) Co., Limited. He has been in the LED Lighting industry ever since 2005. He is an expert in sales & marketing, and factory management. He likes bodybuilding, and he is also a crazy Apple Fan! He is a hard-working guy and loves to learn and try new things.

Email: tom@unitopledstrip.com WhatsApp: +86-18680307140

Leave a Reply

Want to join the discussion?Feel free to contribute!