Looking to buy LED lysbånd? Whether you’re a seasoned pro or new to the world of LED strips, this article is for you.

I am Tom Woo from Unitop (Kina) Co, Limited, a professional manufacturer of LED strips since 2005. With over 17 years of experience in the LED lighting industry, I hope my article will help you.

This article will help you identify the key factors determining the quality of LED strips and some knowledge you need to know before making the right purchase for your project.

Lad os dykke lige ned i det!

What are LED strip lights?

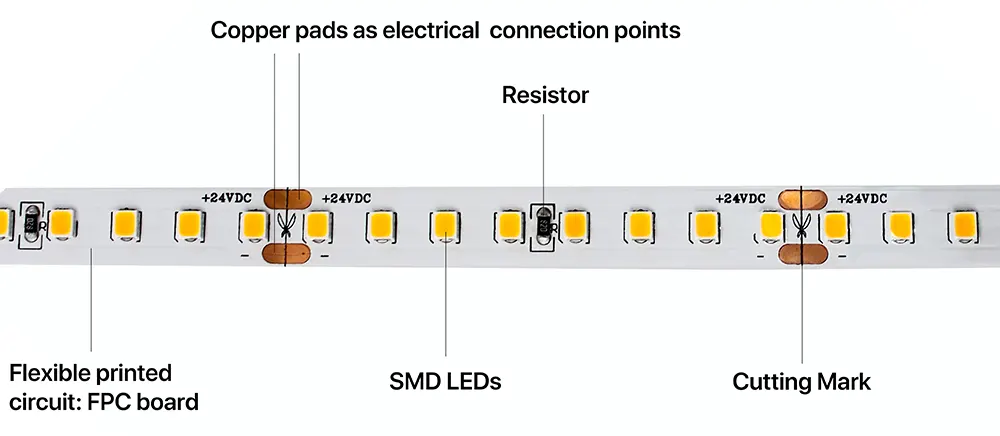

LED strip lights, also known as LED tape lights, LED ribbon lights, or LED light strips, are a type of lighting solution that consists of a series of surface-mounted device (SMD) LEDs and other electrical components soldered onto a flexible print circuit (FPC) board. When connected to a power supply, these components work together perfectly to produce a strip-shaped light, hence the name “LED strip lights.”

Several key components make up an LED strip light, including SMD LEDs, an FPC board, resistors, and 3M double-sided adhesive tape. These components are essential for the proper functioning and durability of the LED strip light.

How do LED strip lights work?

To use white LED strip lights or single-color strip lights, you’ll need to connect them to a power supply with an appropriate voltage. Once the power supply is connected to your home electrical system, the LED strips will produce light. You can also install an LED dimmer to control the brightness of these strip lights.

If you’re using RGB, RGBW, RGBWW, or tunable white/CCT adjustable white LED strips, you’ll need to install an LED controller between the LED strip light and the power supply. This will allow you to change the color or color temperature of the LED strips as desired.

A new LED strip light called high voltage LED strip makes the installation even easier. It can be connected directly to AC230V, meaning no power supply is needed.

Top 10 advantages of LED strip lights

LED strip lights are becoming increasingly popular for residential, commercial, and architectural lighting applications due to the following ten advantages:

1. Easy installation

LED strip lights are thin and flat, making them easy to hide in small spaces and creating the effect of seeing the light without seeing the fixture. They come with 3M tape and can be installed without the help of a professional.

2. Flexibility

LED strip lights can be bent to create different smooth and beautiful linear lighting shapes. They are also easy to apply to curved surfaces.

3. Cuttable and linkable

Light strips can be cut into small sections to fit the size you need and can be linked together using solderless connectors or by soldering.

4. Low voltage

Strip lights operate on 12V or 24V DC low voltage, making them extremely safe for people of all ages, including children.

5. Fully dimmable

LED strip lights are fully dimmable and can be easily adjusted to the desired brightness level when used with dimmers or controllers. Please find this article on how to dim LED strips.

6. Low power consumption

LEDs are environmentally friendly lights with very low power consumption. Using LED strips can save a lot on energy costs over time.

7. Low heat generation

LED strip lights consume low power, producing less heat in the surrounding area while still producing amazing bright light.

8. Great for creating atmosphere

LED strip lights are perfect for creating a variety of lighting environments. There are many options for different color temperatures, including warm white, natural white, daylight white, cool white, tunable white, red, green, blue, RGB, RGBW, RGBW, RGBWW, and more.

9. Multiple applications

LED strip lights are versatile and can be used for home, office, commercial and industrial lighting, etc.

10. Waterproof and non-waterproof

Indoor non-waterproof(IP20) and outdoor waterproof LED strip lights(IP65~IP68) are available.

Top 9 considerations before buying LED strip lights

Below is a comprehensive overview of top considerations before buying LED strip lights.

1. Color and CCT

The term “CCT” stands for Correlated Color Temperature. It measures the color appearance of a white light source and is expressed in degrees Kelvin (K). It is used to describe the hue of a light source, with lower temperatures appearing warmer (more yellow/orange) and higher temperatures appearing cooler (more blue). Here is a breakdown of some common CCTs and their general usage:

- 1800K – This CCT is very warm and has a strong orange/yellow hue. It is often used in environments where a cozy, warm ambiance is desired, such as restaurants or bars.

- 2400K – This CCT is close to orange or brownish-yellow. It is a very warm light with a reddish and yellow tone. It is often used in retail, hospitals, and other special events like weddings, parties, and other gatherings.

- 2700K – This CCT is similar to the light color of incandescent bulbs. It is also considered warm, but not as warm as 1800K. It has a softer, more neutral orange/yellow hue. It is often used in residential, such as living rooms or bedrooms.

- 3000K – This CCT is similar to the light of halogen lamps. It is considered a “warm white” and has a neutral white hue with a slight yellow/orange tint. It is often used in general lighting applications, such as in offices or schools.

- 3500K – This CCT is also considered a “warm white,” but it has a slightly cooler hue than 3000K. It is often used in retail environments, as it is believed to make products appear more appealing.

- 4000K – This CCT is considered a “natural white” and has a neutral white hue with a slight blue tint. It is often used in task lighting applications, such as in kitchens or workshops.

- 5000K – This CCT is considered a “daylight” white with a slightly cool, blue-white hue. It is often used in environments where high visibility is required, such as in hospitals or laboratories.

- 6500K – This CCT is also considered a “daylight” white, but it has a cooler hue than 5000K. It is often used in photography and videography, as it closely approximates natural daylight.

- 10000K – This CCT is very cool and has a strong blue hue. It is not often used in general lighting applications but may be used in special effects or for aesthetic purposes.

You can refer to the below chart for a more detailed understanding.

Adjustable white LED strip lights, also known as tunable white strip lights, or CCT adjustable LED strips, offer a range of color temperatures from 2700K to 6500K. These lights are created using a combination of warm white and cool white LEDs on the same flexible printed circuit board. By adjusting the brightness levels of the warm and cool white LEDs, various color temperatures can be achieved.

In addition to adjustable white strip lights, single-color options are available such as red, green, and blue. For even more versatility, multicolor RGB, RGBW, or RGBWW LED strips are also available.

2. Indoor or outdoor

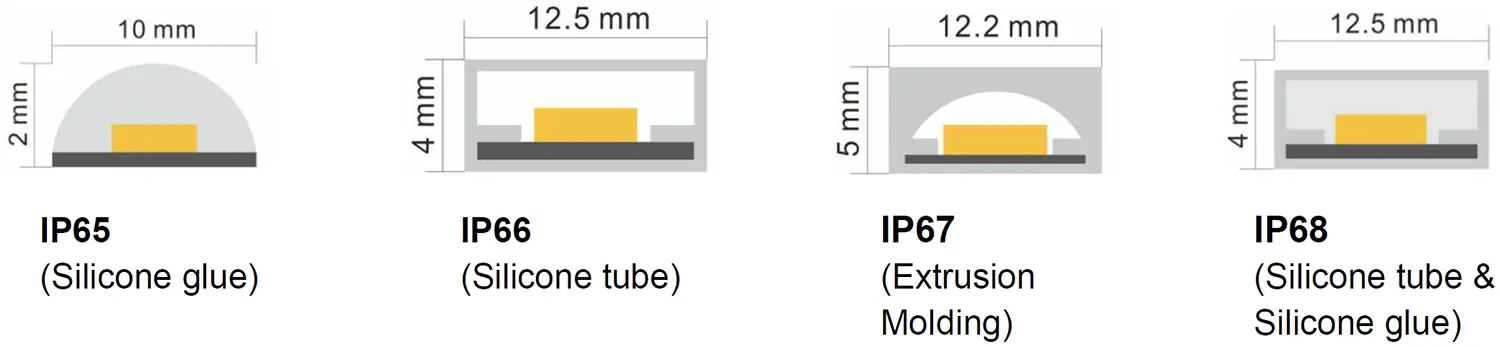

Generally speaking, when choosing LED strip lights for indoor use, select those with an IP20 rating. For outdoor or semi-outdoor applications, it is recommended to use waterproof LED strip lights with an IP65 rating or higher.

Keep in mind that the appropriate IP rating will depend on your application’s specific needs and requirements. It is always a good idea to carefully consider the potential exposure to moisture and choose a LED strip light with a suitable rating to ensure safe and reliable operation.

For example, it is recommended to use LED strip lights with at least an IP65 rating for kitchen and bathroom applications. This rating indicates that the lights are protected against low-pressure water injection, making them suitable for damp environments.

3. 12VDC or 24VDC

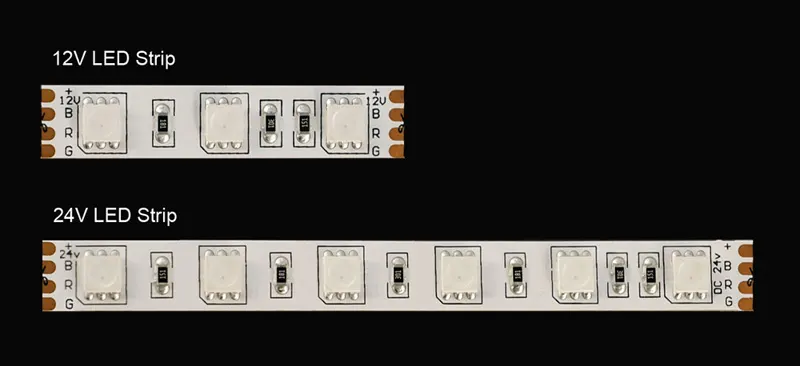

There are a few factors to consider when choosing between 12V and 24V LED strip lights.

Many customers prefer 12V LED strips because they are familiar with them and because 12V power supplies are more readily available on the market.

Additionally, the cuttable section of 12V LED strip lights is typically smaller than that of 24V strips, making it easier to cut and customize the lights to the desired length.

12V LED strip lights are also popular for use in vehicles, boats, and luxury yachts, as these types of vehicles typically have 12V power systems.

However, 24V LED strip lights have become increasingly popular in recent years.

One advantage of 24V strips is that they operate with half the current of 12V strips, which means they have a longer lifespan. Additionally, more product variations are available in the 24V range, providing more options for customers.

24V LED strip lights are also a good choice for projects requiring continuous, long LED strips installations, as the voltage drop is typically smaller for 24V strips.

Constant current LED strip lights can also help mitigate the voltage drop issue. Such LED strips can run continuously up to 50m(around 160ft) with one power supply. Still, these strips are typically more expensive due to the additional electrical components and longer production lead time.

At Unitop, we offer both 12V and 24V LED strip lights to meet the diverse needs of our customers. And our most popular models are 24V. If you have any specific requests or questions, please feel free to contact us.

4. Brightness

Brightness is an important consideration when choosing LED strip lights, as it plays a significant role in creating ambiance through both its intensity and color. In the lighting field, brightness is typically measured in lumens. This value reflects the amount of light produced by a light source and can be used to compare the brightness of different lights.

Lumen

Lumen is the unit of measure for the total amount of visible light emitted over a specific period. It indicates the brightness of the light produced by a source. Electricians often use foot-candle, a unit commonly used in the US, to describe the light intensity. One foot candle is equivalent to one lumen per square foot, or the amount of light produced by a typical wax candle placed one foot away.

When selecting LED strip lights, it is crucial to consider the brightness, typically indicated in lumens per unit length. However, be aware that different suppliers may use other units of measurement, and it is necessary to convert these values for an accurate comparison.

For example, one strip may be marked as “240 lumens/ft” while another may be marked as “700 lumens/meter.” To compare these strips, it is necessary to convert the lumens/ft value to lumens/meter by multiplying it by the conversion factor of 3.28. In this case, the first strip would be 787.2 lumens/meter, making it brighter than the second strip.

If you need a brighter LED strip light, choose one marked with a higher lumen value per unit length. Just be sure to carefully compare the values using the appropriate units of measurement to ensure an accurate comparison.

Luminous efficacy

Luminous efficacy is another important factor related to brightness. It is the ratio of the lumen value of a light strip to its power consumption. In other words, it measures how efficiently a light strip uses power to produce light.

An LED strip light with a higher luminous efficacy will produce more lumens of light when consuming the same amount of power. This means that it will be more energy-efficient and cost-effective to operate.

Relationship between brightness and power

The brightness of an LED strip light is also related to its power consumption. Usually, the more power an LED strip uses, the brighter it will be. However, it is important to consider the luminous efficacy of the strip when determining how much power is needed to achieve the desired brightness level.

How many lumens do I need?

When installing LED strip lights in homes, it is common to wonder how many lumens are needed for a particular space. The number of lumens per square foot required to properly and comfortably illuminate an area can vary depending on the specific needs and preferences of the user.

Generally, a higher lumen count will be needed for brighter, more vibrant lighting, while a lower one may be sufficient for more subdued ambient lighting.

To achieve optimal lighting for various spaces, the following table offers a general guideline for the number of lumens per square foot needed:

| Anvendelse | The number of lumens per square foot |

|---|---|

| Bedroom lighting | 10-20 lumens per square foot |

| Stair and hallway lighting | 10-30 lumens per square foot |

| Under cabinet lighting | 20-40 lumens per square foot |

| Under counter lighting | 20-40 lumens per square foot |

| Kitchen island kickboard lighting | 20-50 lumens per square foot |

| Bathroom lighting | 50-70 lumens per square foot |

| Kitchen countertop lighting | 60-80 lumens per square foot |

Keep in mind that these are just general recommendations and the actual number of lumens needed may vary based on the specific needs and preferences of the user.

5. LED density and LED types

LED density refers to the number of LEDs per meter or foot on a LED strip light. For example, a strip light may have 60 LEDs per meter or 18 LEDs per foot.

How does LED density influence the LED strip lights’ brightness?

LED density plays a key role in the brightness of LED strip lights. A higher-density strip, which has more LEDs per meter or foot, will typically be brighter than a lower-density strip. This comparison is based on the same type of LED and the same current on the LEDs.

Klik her for at tilføje din egen tekst

How does LED density influence light distribution?

In addition to brightness, LED density can also impact light distribution from LED strip lights. When the distance between individual LEDs is not uniform or too much, it can result in the appearance of “light spots” or visible areas of concentrated light. Achieving a smooth, even light distribution typically requires a higher LED density and careful placement of the LEDs.

Distance range in between LED and also diffuser

The distance between the LED and the diffuser can affect the light distribution from LED strip lights. To understand this, imagine standing 10 meters away from a wall and shining a flashlight on it. The entire wall area would be lit, indicating good light distribution. As you move closer to the wall, the lit area becomes smaller until it is the same size as the flashlight head, at which point the light distribution becomes poor due to the noticeable light spots.

Like a flashlight, an LED is a point source of light, so if light spots are a concern, one solution is to increase the distance between the LED and the diffuser. For example, when using aluminum profiles to install LED strip lights, you can choose deeper profiles to achieve a longer distance between the LED and the diffuser.

Distance between two surrounding LEDs

The closer the distance between surrounding LEDs, the higher the LED density of strip light and the better the light distribution. This is because the closer the distance, the easier it is for the LEDs to cover each other’s blind spots.

In cases where the distance between the LED and diffuser cannot be increased due to installation constraints, choosing a strip light with a higher LED density can help improve light distribution and reduce the appearance of light spots.

Some of our LED strip lights are designed specifically for optimal light distribution. These strips feature high-density LEDs and can provide excellent light distribution even when used in shadow aluminum profiles. These lights also offer higher lumen output, lower current, less heat generation, and longer lifespan.

LED types

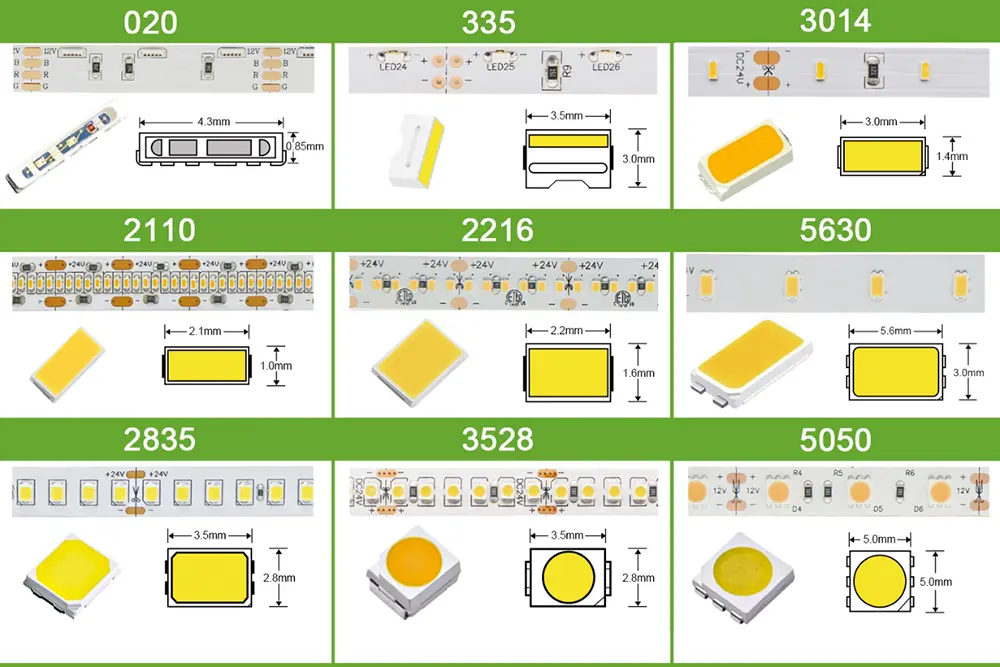

SMD LED package types are often identified by a number, such as 3538, 2835, 5050, or 2216, which refers to the size of the LED in millimeters.

SMD3528 LEDs have dimensions of 3.5mm x 2.8mm and a height of 1.9mm. These LEDs have a power of 0.06W and can produce white or colored light. SMD3528 LED strips have a long history of use, but they may not be as cost-effective as newer SMD2835 LEDs.

SMD2835 LEDs have dimensions of 2.8mm x 3.5mm and a height of 0.7mm. These LEDs have a power of 0.1W, 0.2W, or 0.5W and can produce white or colored light. SMD2835 LED strip lights are currently the best-selling type on the market.

SMD5050 LEDs have dimensions of 5.0mm x 5.0mm and a height of 1.6mm. These LEDs have a power of 0.2W and can produce white light, colored light, RGB, RGBW, or RGBWW. The most outstanding feature of SMD5050 LEDs is they can put many chips inside one single led. This makes them widely used in the multi-color solution.

SMD2216 LEDs have dimensions of 2.2mm x 1.6mm and a height of 0.6mm. These LEDs have a power of 0.06W, 0.15W, or 0.2W and are made to produce white light. SMD2216 LEDs have the smallest ad ultra-slim body, making it best to make the thinnest LED strips.

There are also other SMD LEDs like SMD3030, SMD3014, SMD5730, SMD5630, etc.

COB (chip on board) LED strip lights are a type of LED lighting that utilizes multiple LED chips bonded directly onto a substrate or printed circuit board. The chips are mounted directly onto the board rather than housed in a separate package, resulting in a more compact and efficient lighting solution. COB LED strip lights are known for their high lumen output and improved heat dissipation; you can not see the light spots when you light them on.

Unitop is a leading manufacturer of LED strip lights in China. Our best-selling LED strips are COB LED lysbånd, SMD2835 LED-strips, high-density 180lm/W LED strips, og 230V AC LED strips.

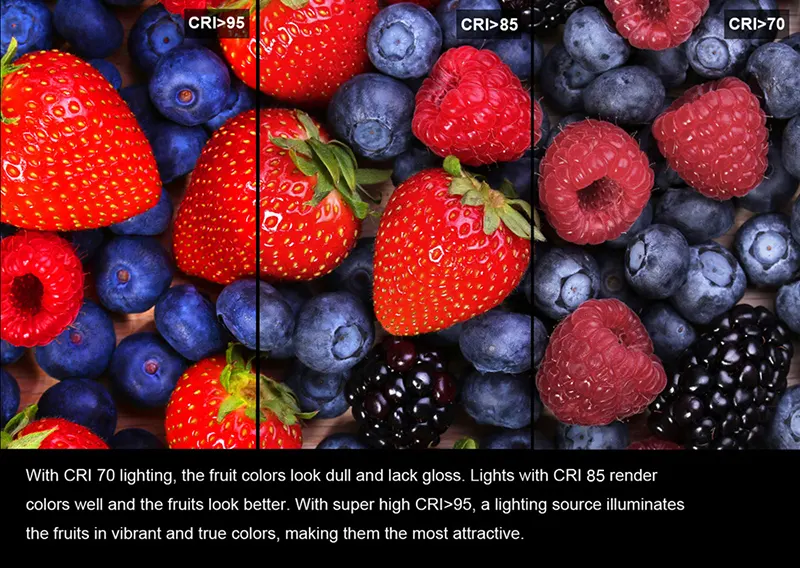

6. CRI or color rendering index

CRI, or color rendering index, is a measure of a light source’s ability to reproduce objects’ colors accurately.

It is based on the idea that the original color of an object can be determined by how it appears when illuminated by sunlight, which has a CRI of 100.

The closer the color of an object rendered by a source of light is to the color of the same things under sunshine, the greater CRI the source of light has.

A light source with a high CRI value will more accurately reproduce the colors of objects compared to one with a lower CRI value.

CRI is important in lighting applications where color is critical, such as in retail settings where the appearance of products can influence customer purchasing decisions.

For example, LED strip lights with a high CRI in a grocery store’s produce section can make the fruit and vegetables look more natural and appealing, while low CRI lighting can make them appear dull and less attractive.

It is also worth noting that long-term exposure to light with a CRI lower than 80 can affect the ability of the human eye to distinguish colors and may cause vision problems. For this reason, it is recommended to use LED strip lights with a CRI of at least 80 for extended use.

Currently, most of our LED strip lights have CRI 90+. For your specialist demands, we additionally bring LED strip lights with CRI 98+.

7. Length and width

LED strip lights are often sold in lengths of 5 meters (16.4 feet) due to voltage drop along the strip. When using a 12V or 24V LED strip, the brightness of the LEDs at the end of a strip longer than 5 meters may be lower than those at the beginning.

It is important to note the length of the strip when purchasing LED lights, as some sellers may offer shorter lengths, such as 2 meters or 3 meters.

LED strip lights also come in various widths, including 4mm, 5mm, 6mm, 8mm, 10mm, and 12mm. The ultra-slim 4mm version is often used for special lighting projects.

8. LED power supply

When deciding between a power adapter and a switch power supply, there are a few things to consider.

1. Power adapters are generally easier to set up and are suitable for small projects, as they can usually power one to two LED strips.

2. A professional branded power supply may be a better choice for medium to large installations as it can provide power for many strip lights.

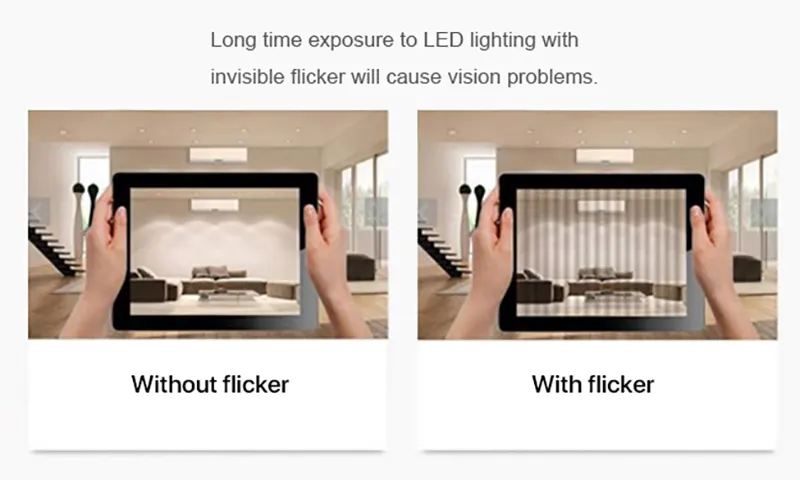

3. It’s important to choose a high-quality power adapter or power supply to avoid flickering. Flickering can be caused by substandard power supplies and can be noticeable or even unseen to the naked eye.

To check for flickering, you can use the video camera mode on your phone to view the strip lighting. Prolonged exposure to LED lights with undetectable flickers can cause vision problems or even headaches.

4. Good quality power supplies, such as MeanWell, can provide the full suggested current for continuous operation. On the other hand, bad quality, substandard power supplies may provide less current than indicated, become hot, and have problems when used for extended periods.

5. Voltage and power of LED strip power supplies

When choosing a power supply for your LED strip lights, it’s important to consider the voltage and power requirements.

Spænding: The power supply voltage should match the LED strips’ voltage. For example, if you have 12V LED strips, you should use a 12V power supply. Similarly, if you have 24V LED strips, you should use a 24V power supply.

Kraft: The power supply should be sufficient to power the LED strips. To determine the power needed, you can use the formula: Power = LED strip length x wattage/meter. For example, if you are installing a 5-meter LED strip with a wattage of 16W/meter, the total power needed would be 5 meters x 16W/meter = 80W.

It’s generally recommended to choose a power supply with a capacity that is 20% higher than the calculated power needed. This allows for some extra capacity and helps to prevent the power supply from running at full load, which can generate excess heat and reduce the lifespan of the power supply.

For the example above, you would need a power supply with a capacity of at least 96W (1 + 20% of 80W). It’s generally safe to choose a power supply with a higher capacity than needed, as it will only provide the power the LED strips require.

For more details, we have a separate article on how to choose LED power supply.

9. Quality

Quality is the result of several factors coming together.

Quality materials

To ensure high-quality LED strip lights, it’s important to use quality materials such as top-quality LEDs, double-sided red copper FPC boards, 3M double-sided tape, and waterproof materials. The quality of these materials can often be assessed by sight and touch.

Good performance

Good performance is also essential for high-quality strip lights. Some factors to consider when evaluating the performance of strip lights include the precision and uniformity of the color temperature, the heat management performance, and the color rendering index (CRI). To be easy on the eyes, LED strip lights should have a CRI of at least 80+.

UL/CE certified

It’s also important to choose LED strip lights that are UL/CE certified in the low-voltage luminaires category.

Excellent service

It’s always a good idea to choose a supplier with excellent before and after-sales customer service, including a product warranty. Unitop offers a 3-year warranty for all our LED strip light products.

What are the most effective LED strip lights?

1. LED

LEDs, also known as LED packages, are crucial in making high-quality LED strip lights. The quality of the LED has a direct and significant impact on the overall quality of the LED strip. Key components of an LED include the LED chip, bracket, lead wire, phosphor, and package glue.

Den LED chip is the most important part of the LED package, as it is the component that produces light. The brand and size of the chip can often indicate its quality level. LED chips from Taiwan Epistar are known for their large size and good color precision and consistency.

In general, LED chips of a larger size will have stronger performance, producing higher brightness and better heat dissipation.

The lifespan of an LED is positively correlated with its heat dissipation ability, so some manufacturers may choose to use smaller chips to lower costs, but this can result in shorter lifespans and fewer lumens from the LED.

Den bracket of a high-quality LED is made of red copper with a silver plating of at least 60u thick. This provides low resistance and good conductivity, allowing for efficient heat dissipation within the LED. Lower-quality LEDs may use iron brackets, are prone to rusting, and have poor heat dissipation capabilities.

To determine if an LED uses a red copper silver-plated bracket, you can carefully split the LED in half and look for the presence of red copper inside.

Den bond wire is used to connect the various components of the LED. High-quality bond wire uses 99.99% purity gold wire that is 1.0 mil gauge. Gold wire is known for its high ductility and pliability, allowing it to withstand the internal stress forces of the adhesive without breaking.

Gold is expensive, so some manufacturers may use lower-quality bond wire, such as copper, to reduce costs. This can result in reduced conductivity, faster degradation, and more heat for the LED.

Den package glue used in a high-quality LED has a high refractive index, which helps to increase the LED’s lumens. The glue should also create a strong bond with the bracket, be moisture-resistant and anti-cracking, and not turn yellow over time.

Phosphor is a crucial component of LEDs. Advanced phosphors include indium gallium nitride (InGaN) and aluminum gallium indium phosphide. The phosphor’s characteristics directly impact the quality of white LEDs, including brightness, color temperature, CRI, and chromaticity coordinates.

Good phosphor should have a concentrated spectrum, slow degradation in brightness, and high temperature resistance.

In summary:

LEDs of the same batch (or “bin”) should all emit light with the same brightness and color temperature, ensuring lighting precision and consistency.

One way to test the quality of LEDs is to apply a 6-8V DC to an LED strip light. If every LED on the strip produces a minor amount of light at the same brightness level, the LEDs have good uniformity. On the other hand, if the brightness of the LEDs varies, with some being brighter and some being darker, the LEDs are of poor quality.

It’s also important to note that for 5050 LEDs with three color chips, it’s necessary to use an RGB controller to test each chip individually. If any chips do not light up, the LEDs are faulty.

2. Flexible printed circuit board( FPC)

The FPC board is where the LEDs are mounted, using layers of copper as a conductor. Double-sided FPC boards, which have copper layers on both the top and bottom sides, are the best option for producing high-quality LED strip lights.

On the other hand, single-sided FPC boards contain less copper and are, therefore, less expensive, but they also have a shorter lifespan and can produce more heat when used in LED strip lights.

How to tell whether an LED strip light uses a single-sided or double-sided FPC board? Single-sided FPC has only one side with circuits printed, and the opposite side looks smooth and distributed color. Double-sided FPC has printed circuits on both sides. So it can be so easy for you to see.

When holding them between two fingers. Double-sided FPC boards are typically thicker, which improves their heat release function.

3. Manufacturing process

One way to determine the quality of an LED strip light’s manufacturing process is to inspect the soldering points of the LEDs. On high-quality strip lights, the soldering points should appear full and shiny. Conversely, soldering points on poor-quality strip lights will appear shriveled and dull.

Seeing is believing! It is also a good idea to visit the factories to double-check all the manufacturing processes before you can place big orders.

4. Authentic 3M double-sided adhesive tape

Almost all stick-on LED light strips use double-sided tape on the back, often marked with the letters “3M”. However, not all of these tapes are authentic 3M brand tape.

Inferior quality tapes may initially provide a good adhesive bond and keep the light strip in place, but they become less sticky over time and may eventually fall off.

In contrast, authentic 3M double-sided tape becomes stronger and more adhesive over time, and the light strip will not fall off unless it is intentionally removed.

The 3M tape used on our waterproof LED strip lights is clear and does not leave any sticky residue on the installation surface when the strip is removed.

5. Waterproof material used

For outdoor waterproof LED strip lights, the type of waterproof material used makes a difference in quality. High-quality waterproof strip lights use silicone waterproofing, which is non-toxic and can be used in products like baby bottle nipples.

Silicone has high light transmittance and does not yellow over time, and it maintains its properties over a wide temperature range (-67°F to 392°F).

In contrast, inferior waterproof strip lights may use cheaper polyurethane (PU) glue as the waterproofing material. PU glue is toxic and unsuitable for indoor use, and it may turn yellow, become brittle, and crack after a few months.

The manufacturing process using PU glue can also result in the PU glue coming into contact with the LED surface, which can alter the color temperature of the light. For example, a normal 6500K LED strip coated with PU adhesive waterproof material may have its color temperature adjusted upwards by about 1000K, resulting in a color temperature of around 7500K-8000K.

What can LED strip lights do?

LED strip lights are extremely versatile and can be used in many applications. They are a popular choice for lighting design professionals because of their creativity and versatility. When properly designed and installed, LED strip lights can be used for ambient, accent, task, and bias lighting.

Ambient lighting

Ambient lighting refers to general or mood lighting, the base level of light in a space. It allows you to move around safely and sets the overall tone in the room.

Accent lighting

Accent lighting is focused on a small area or feature in a room and is often used to highlight a particular area or make it stand out. Under-counter LED strip lighting is an example of accent lighting, often used to showcase artistic items, photographs, or trophies.

Task lighting

Task lighting is used to help you work by increasing focus and sharpness and lighting specific items or areas. It is often used in office desks and kitchen countertops, and under-cabinet strip lighting can be a good example of task lighting.

Bias lighting

Bias lighting is a backlight behind TVs, monitors, or screens to add soft lighting to the usually dark background. It is used to improve the performance of television displays and reduce eye strain for viewers.

With the above illumination capabilities, LED strip lights have been used for many applications, including residential, commercial, architectural, and industrial lighting. Some common applications for LED strip lights include:

Under-cabinet LED strip lights

LED strip lights are popular for their low profile and easy installation. They are straight and flat, making them easy to conceal in tight spaces like under cabinets or shelves.

Ceiling cove LED strip lights

LED strip lights are also popular for ceiling cove lighting, a popular form of ambient lighting in modern homes. Unlike downlights that require an opening in the ceiling, LED strip lights are flat and slim, making them ideal for hiding in ceiling coves.

Warm white ceiling lighting creates a cozy and relaxing atmosphere, while cool white ceiling lighting creates a refreshing environment. RGB ceiling lights are often used for party and holiday lighting events.

Room LED strip lights

LED strips are also a popular choice for use in rooms and can be used for indoor and outdoor installations. They are often used in lighting design trends by professionals.

Please find below the application ideas:

Under cupboard lighting.

Modern cooking area island lighting.

Under counter lights.

Ceiling concealed cove lights.

Bedroom lighting.

LED recessed lighting.

Washroom illumination.

Closet lights.

Living room lights.

LED stair step lights.

Garage illumination.

Stage illumination.

Decking illumination.

Schoolhouse lighting.

Landscape lights.

Restaurant and bar lights.

TV LED strip lights

LED strip lights are a great option for creating bias lighting for television, computer monitors, home theater screens, etc. LED backlight strips for television produce a weak bias light that can optimize TV contrast performance and reduce eye strain for viewers.

Without bias lighting, the area around a TV or monitor is typically dark, while the screen produces high levels of illumination. This high contrast can cause eye strain if viewers are exposed to it for long periods.

Bias lighting helps to reduce this high contrast by providing a low level of light in the surrounding area, which reduces eye strain for viewers. It’s important to note that bias lighting does not shine directly toward viewers and is designed to significantly lower the high contrast between the screen and the surrounding area.

Vehicle-use LED strip lights

LED strip lights are often used in automotive vehicles and recreational vehicles because of their flat, low-profile design. This makes them ideal for use in the limited space found in cars and RVs. In comparison to other high-profile lighting options, such as light bulbs, strip lights take up less space during installation, allowing for more distance between the lights and occupants and creating more space for people in vehicles.

LED strip lights for Christmas, vacations as well as parties.

More and more people are using RGB LED strip lights for Christmas, holidays, and celebrations because they operate at a low voltage (12V or 24V) and are easy to install.

RGB LED strip lights can produce a wide range of colors and lighting effects and can even be synced to music for a dynamic lighting experience. These features make RGB strip lights popular for creating a festive atmosphere for holidays and events.

LED strip lights for sign

LED strip lights are also used as backlighting for LED signage and channel letters. Their low profile and high brightness make them ideal for use as a backlight in these applications.

For example, LED strips are often used to create an attractive halo effect around company logos on the wall of a reception area. Our S-Shape or zig-zag LED strip lights are designed to make turns easily, making them perfectly suited for backlighting installation, even for small sign letters.

In summary, LED strip lights are highly versatile and can be used for various applications. Whether you want to be creative or follow the lead of others, you can enjoy DIY lighting with LED strip lights.

Customized LED strip lights

Many of our clients have unique ideas for strip lights. If our standard products don’t meet your needs, we can custom-make any strip lights you desire. Just tell us your idea, and we will make it a reality in China. We design and create samples for you, then provide you with the final, perfect LED strips.

Further LED strip lights ideas

If you are interested to know more amazing LED strip light applications, we have a separate artikel for you to check in more detail.

Where to get the best LED strip lights?

We are one of the leading manufacturers of LED strip lights and offer high-quality products on the market.

While lower-priced LED strip lights may seem like a good deal, they often lack the quality, safety, and lifetime of more expensive options.

Cheap LED strips may not meet necessary standards and may not be made with durable materials or designs. It’s important to consider the value of the product rather than just the price and choose LED strips that will meet your needs and provide the best value.

Different lighting applications have different requirements, and it’s important to consider your specific needs before choosing LED strips. A focus on brightness alone can waste resources and potentially harm people, so it’s important to carefully consider the illumination needs of your project and choose the best LED strips accordingly.

Our sales team can help you find the best LED strips for your project at a competitive price directly from the factory.

Kontakt os immediately, please!

Som konklusion

How to intelligently pick out the appropriate LED lysbånd? After reading the above, you are already a specialist. If you need anything else about strip lights, we are always here waiting for your further contact.

Tom er nu salgschef for Unitop (Kina) Co, Limited. Han har været i LED-belysning industrien lige siden 2005. Han er ekspert i salg og marketing samt fabriksledelse. Han kan lide bodybuilding, og han er også en vild Apple-fan! Han er en hårdtarbejdende fyr og elsker at lære og prøve nye ting.

E-mail: tom@unitopledstrip.com WhatsApp: +86-18680307140

Skriv en kommentar

Vil du deltage i diskussionen?Du er velkommen til at bidrage!