Frustrated with LED light strips that refuse to stick? You’re in good company. Learn the secrets behind this frequent dilemma and master the art of ensuring your lights firmly adhere, effortlessly illuminating any area.

Improper adhesion of LED light strips often results from unsuitable surface conditions, inferior adhesive quality, or flawed application techniques. A meticulously clean, flat surface combined with premium-quality strips enhances sticking power.

Delve into our comprehensive guide for foolproof strategies to secure your LED light strips. Embark on a journey to illuminate your environment, minus the frustration.

Diagnosing Adhesion Failures in LED Light Strips

When your sleek, vibrant LED light strips start to sag or peel off, the allure of your carefully designed space begins to dim. These adhesion failures can often be traced back to a variety of sources, each affecting the integrity of the bond between the strip and the surface. Environmental factors such as humidity and heat can weaken adhesive bonds over time, making them less sticky and more prone to peeling. On the technical side, the inherent quality of the adhesive used in the LED strips plays a significant role. If the adhesive is of low quality, it won’t matter how ideal the conditions are; the strips will eventually start to come off.

Moreover, the condition of the surface itself is paramount. Surfaces that are dirty, oily, or uneven present challenges for any adhesive, leading to poor attachment and eventual failure. Recognizing these factors is crucial in troubleshooting and resolving adhesion issues with LED light strips, setting the stage for a more successful installation.

Prepping Surfaces for Optimal Adhesion

The foundation of a successful LED strip light installation lies in the preparation of the surface. Ensuring that the surface is clean, dry, and smooth is paramount to achieving optimal adhesion. Start by thoroughly cleaning the area with a suitable cleaner to remove any dust, grease, or other contaminants that could interfere with the adhesive’s ability to bond. Once cleaned, a final wipe with isopropyl alcohol can remove any residual oils and ensure the surface is perfectly prepped. For surfaces that are inherently difficult for adhesives to bond to, such as textured walls or beneath cabinets where the surface may not be perfectly smooth, consider using an adhesive promoter. These substances are designed to create a more adhesive-friendly surface, providing a stronger bond between the strip and the surface. Additionally, for particularly challenging areas, applying a strip of smooth tape can offer a uniform surface for the LED strips to adhere to, mitigating issues related to surface irregularities.

Selecting High-Quality LED Light Strips

The market for LED light strips is vast, with a wide range of options available to consumers. However, not all LED strips are created equal, especially when it comes to their adhesive backing. For installations that last, selecting high-quality LED light strips is a necessity. Renowned brands such as Philips and Govee are celebrated for their commitment to quality, including the durability and reliability of their adhesive. These products often come at a premium but offer peace of mind through enhanced sticking power and longevity. When shopping for LED strips, it’s important to look for signs of quality, such as the thickness of the adhesive layer, the type of adhesive used (e.g., 3M adhesive), and reviews or testimonials regarding the product’s performance over time. Investing in higher-quality LED light strips can save time, frustration, and money by reducing the need for frequent replacements or adjustments due to adhesive failure.

Innovative Solutions to Enhance Adhesion

In the world of LED light strip installation, encountering surfaces where traditional adhesives falter is not uncommon. This challenge has led to the development and adoption of innovative solutions designed to secure LED strips in place, regardless of the environmental or surface challenges present. Double-sided tapes have emerged as a popular choice, offering a stronger bond than standard adhesives provided with most LED strips. These tapes are engineered to withstand factors that typically weaken adhesive bonds, such as temperature fluctuations and moisture.

Adhesive promoters are another groundbreaking solution. Applied directly to the surface before installing the LED strip, these promoters significantly increase the bond strength between the surface and the adhesive. This makes them particularly useful for surfaces that are traditionally challenging for adhesives, such as porous materials or those with a high oil content.

Mechanical fasteners, though less commonly used, provide an alternative route for securing LED strips. These can range from simple clips to more complex bracket systems, offering a physical anchor for the strips. This method is especially advantageous in environments where chemical adhesives might degrade over time due to exposure to harsh conditions.

Maintenance Tips to Ensure Longevity

The longevity of LED light strips is not solely dependent on the initial installation quality; ongoing maintenance plays a crucial role as well. Protecting your LED strips from moisture is paramount, as water can degrade the adhesive over time, leading to peeling and eventual failure. Similarly, excessive exposure to direct sunlight can heat the adhesive beyond its tolerance, weakening its bonding strength. Regular inspections can identify early signs of peeling or detachment, allowing for prompt intervention before minor issues escalate into more significant problems. Simple actions, such as pressing down on areas starting to lift or applying additional adhesive, can significantly extend the life of your installation. This proactive maintenance approach ensures that your LED light strips continue to illuminate your space beautifully for years to come.

Leveraging Alternative Mounting Methods

When traditional adhesives simply aren’t up to the task, or when you’re dealing with particularly challenging installation environments, turning to alternative mounting methods can provide a robust solution. Mounting clips and brackets offer a mechanical means of securing LED strips, bypassing the reliance on chemical adhesives altogether. These methods anchor the strips directly to the surface, ensuring stability even in the face of environmental factors that would typically compromise adhesive bonds.

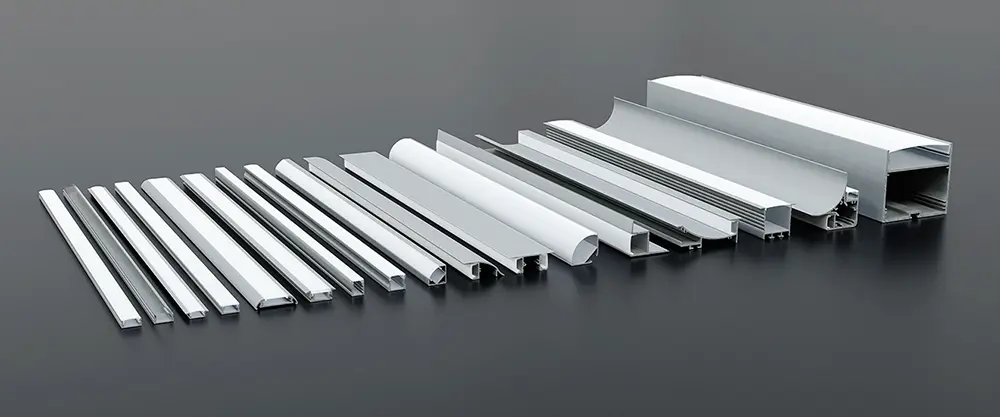

Aluminum channels serve a dual purpose; they not only secure the LED strips but also enhance the visual appeal of the installation. These channels provide a sleek, uniform housing for the strips, protecting them from dust and physical damage while also aiding in heat dissipation, further extending the lifespan of the LEDs.

These alternative mounting methods are particularly beneficial in areas with high heat and humidity levels, environments known to challenge the efficacy of standard adhesives. By opting for these solutions, you can ensure a secure, long-lasting installation that maintains both the functionality and aesthetic appeal of your LED lighting setup.

Comprehensive LED Strip Light Resources

Delving into the world of LED lighting requires a keen understanding of the nuances that distinguish various LED technologies. COB (Chip on Board) and SMD (Surface Mounted Device) LEDs represent two of the most prevalent types, each with unique advantages. COB LEDs are renowned for their ability to emit a uniform light beam, making them ideal for applications where minimal shadowing and maximum light consistency are desired. On the other hand, SMD LEDs offer versatility in color and size, making them suitable for a wide range of applications, from intricate backlighting to vibrant architectural features.

Achieving a dotless finish in LED strip installations is a sought-after skill, especially in professional settings where seamless lighting is paramount. This involves careful selection of LED density and diffusion techniques to create a continuous line of light without the common ‘dot effect’ seen with lower-density strips. Mastering these techniques not only enhances the visual appeal of a project but also maximizes the performance of the lighting installation, ensuring even illumination and reducing glare.

The Role of Proper Adhesive in LED Lighting Projects

The choice of adhesive in LED lighting projects goes beyond mere technicality; it’s a critical factor that influences the longevity, performance, and aesthetic quality of the installation. A common pitfall in LED strip applications is the underestimation of the adhesive’s role, leading to premature failure and maintenance challenges. This section highlights the importance of conducting thorough analyses of potential failure scenarios, such as adhesive degradation due to environmental conditions or improper surface preparation.

Selecting the best adhesive requires an understanding of the specific demands of each environment. For instance, outdoor installations or areas with high humidity levels necessitate adhesives designed for waterproof and high-hold applications. Conversely, indoor installations might prioritize ease of removal or adjustability. By emphasizing the selection of high-quality adhesives tailored to the project’s needs, this segment underlines the foundational role of proper material selection in achieving durable, visually appealing LED lighting installations.

About LED Lighting Solutions

The evolution of LED technology has ushered in a new era of lighting solutions characterized by an unprecedented blend of efficiency, versatility, and aesthetic appeal. LEDs have transformed how we think about lighting design, allowing for innovative applications that extend far beyond traditional fixtures. This section explores the advancements in LED technology, highlighting how these developments have expanded the possibilities for creating both functional and decorative lighting environments.

From the adaptability of LED strips that contour architectural nuances to the energy efficiency that makes large-scale installations sustainable, LED technology caters to a broad spectrum of lighting needs. The exploration of LED advancements reveals the potential for customizing lighting solutions to fit the unique demands of both residential and commercial spaces, offering insights into how LEDs can enhance ambiance, improve functionality, and contribute to the overall design aesthetic of modern spaces.

Ofte stillede spørgsmål

Why won’t my LED light strips stick properly?

Improper adhesion can result from several factors, including unclean surfaces, low-quality adhesive backing, or extreme environmental conditions. Ensure the surface is clean and dry, and consider investing in higher-quality LED strips for better results.

How can I prepare surfaces for optimal LED strip adhesion?

Start by thoroughly cleaning the surface to remove dust, grease, or any residue. For challenging surfaces, using an adhesive promoter or applying a primer can significantly improve adhesion.

What are the best-LED light strips that won’t easily peel off?

High-quality LED strips from reputable brands like Philips and Govee are known for their durable adhesive and long-lasting performance. Look for products with positive reviews focusing on their sticking power. If you are looking for big quantity LED strips. You can buy directly from Chinese manufacturers like Unitop.

Can I use double-sided tape for my LED strip lights?

Yes, double-sided tape can be an effective solution for enhancing the adhesion of LED strips, especially in areas where the original adhesive might not be sufficient.

How do I extend the lifespan of my LED light strips?

Regular maintenance, including keeping them free from dust and moisture and avoiding direct sunlight, can significantly extend their lifespan. Address any peeling issues immediately to prevent further damage.

Are there any alternative mounting methods for LED strips?

Yes, alternative methods such as mounting clips, brackets, and aluminum channels not only secure your LED strips but can also enhance their aesthetic appeal, providing a more professional finish.

What’s the difference between COB and SMD LED lights?

COB (Chip on Board) LEDs offer a more uniform light output with fewer shadows, making them ideal for areas requiring consistent illumination. SMD (Surface Mounted Device) LEDs are versatile in color and size and suitable for a wide range of decorative and task lighting applications. For more details, you can read this article.

How can I achieve a dotless finish with LED strip lights?

To achieve a dotless finish, select LED-strips med høj densitet and use a diffuser or cover that helps spread the light evenly. This technique minimizes the appearance of individual LED dots for a smooth, continuous light output.

Why is choosing the right adhesive important for LED lighting projects?

The right adhesive ensures that your LED strips remain securely in place over time, maintaining both the aesthetic and functional integrity of your lighting project. It’s essential for preventing premature failures due to environmental conditions or surface incompatibilities.

How have LED lighting solutions evolved to enhance modern spaces?

LED technology has advanced significantly, offering energy-efficient, versatile lighting options that can be tailored to fit any design aesthetic. From creating ambient lighting in homes to enhancing the functionality of commercial spaces, LEDs have become integral to modern lighting design.

Konklusion

Concluding our journey through the world of LED light strips, remember that successful installation hinges on understanding the basics—choosing the right product, preparing your surfaces meticulously, and considering alternative adhesion methods when necessary. By harnessing these insights and techniques, you can ensure your LED lighting projects shine brightly and last longer, transforming any space with the glow of innovation and reliability. Whether you’re a DIY enthusiast or a professional installer, the path to flawless LED lighting begins with knowledge and ends with the satisfaction of a job well done.

In wrapping up our exploration into LED light strips, we spotlight Unitop, a frontrunner among China’s elite LED lysbånd og neon flex manufacturers. Embodying innovation and quality, Unitop stands ready to illuminate your projects with unmatched expertise. Should you have any inquiries or specific needs, don’t hesitate to række ud. Dive into a world where excellence in LED solutions is just a conversation away with Unitop—where your lighting visions become reality.

Relaterede artikler

Tom er nu salgschef for Unitop (Kina) Co, Limited. Han har været i LED-belysning industrien lige siden 2005. Han er ekspert i salg og marketing samt fabriksledelse. Han kan lide bodybuilding, og han er også en vild Apple-fan! Han er en hårdtarbejdende fyr og elsker at lære og prøve nye ting.

E-mail: tom@unitopledstrip.com WhatsApp: +86-18680307140

Skriv en kommentar

Vil du deltage i diskussionen?Du er velkommen til at bidrage!