“Lighting is the first element of design; without it, there is no color, form, or texture,” said Benjamin Noriega-Ortiz. This statement rings especially true when discussing the brightness of LED Neon Flex lights. Imagine walking into a vibrant downtown area, where the streets are adorned with bright, colorful signs that draw you in. The impact of these lights is undeniable, but have you ever wondered what makes some LED Neon Flex lights shine brighter than others?

The brightness of LED Neon Flex lights is not just about aesthetics; it plays a crucial role in their functionality and effectiveness. Surprisingly, according to the Department of Energy, LED lights are up to 80% more efficient than traditional lighting, translating into significant energy savings and lower operational costs. Understanding the factors that influence the brightness of these lights can help you make informed decisions, whether you’re lighting up a storefront or creating an eye-catching display for an event.

In this article, we’ll explore the key elements that affect the brightness of LED Neon Flex lights. From the quality of LED chips to the importance of proper heat management, we’ll delve into each factor to provide a comprehensive guide. Read on to discover how you can optimize the brightness of your LED Neon Flex installations and ensure they perform at their best.

What is LED Neon Flex?

LED Neon Flex is a modern lighting solution miming traditional neon lights while offering enhanced durability and energy efficiency. It is suitable for indoor and outdoor use and is composed of LED chips embedded within a flexible casing. Unlike fragile glass neon lights, LED Neon Flex is made from robust materials that can be bent and shaped into various designs, making it ideal for custom installations. This lighting provides a continuous, uniform glow through high-quality LED chips precisely spaced within the casing. Its versatility and weather-resistant properties make it perfect for architectural accents, retail displays, signage, and decorative lighting, all while consuming significantly less power than traditional neon lights.

Understanding LED Neon Flex Brightness

Why Brightness Matters in LED Neon Flex

Brightness is crucial for LED Neon Flex, impacting visibility, color vibrancy, and overall effectiveness. In signage, sufficient brightness ensures visibility from a distance, attracting attention and conveying messages effectively. For decorative accents, proper brightness enhances a space’s ambiance and aesthetic appeal. In functional lighting applications, such as pathways or work areas, adequate brightness improves safety and usability. Selecting the right brightness level involves considering the intended use and environment to ensure optimal performance and visual impact.

The Science Behind LED Brightness

The brightness of LED lights is influenced by the efficiency of the LED chips and the power supplied to them. Light output, measured in lumens, indicates the amount of visible light produced. High-quality materials and precise engineering in LED chips result in more efficient light conversion and higher brightness. Consistent power supply is essential for maintaining steady brightness, as fluctuations can cause flickering or dimming. Additionally, the physical design of LED chips affects light distribution, impacting how bright they appear in various settings.

Key Metrics for Measuring Brightness

- Lumens: This measures the total amount of visible light emitted by the LED. Higher lumen values indicate brighter lights.

- Lux: This metric measures light intensity on a specific surface area, which is crucial for applications needing concentrated light, like task lighting.

- Color Temperature: Measured in Kelvin (K), it describes the color characteristics of the light, ranging from warm (2700K-3000K) to cool (5000K-6500K). Warm light creates a cozy atmosphere, while cool light provides a brighter, more alert ambiance.

Understanding these metrics helps select the appropriate LED Neon Flex for specific needs and tailor lighting designs to meet functional and aesthetic requirements.

LED Chip Quality

Types of LED Chips Used in Neon Flex

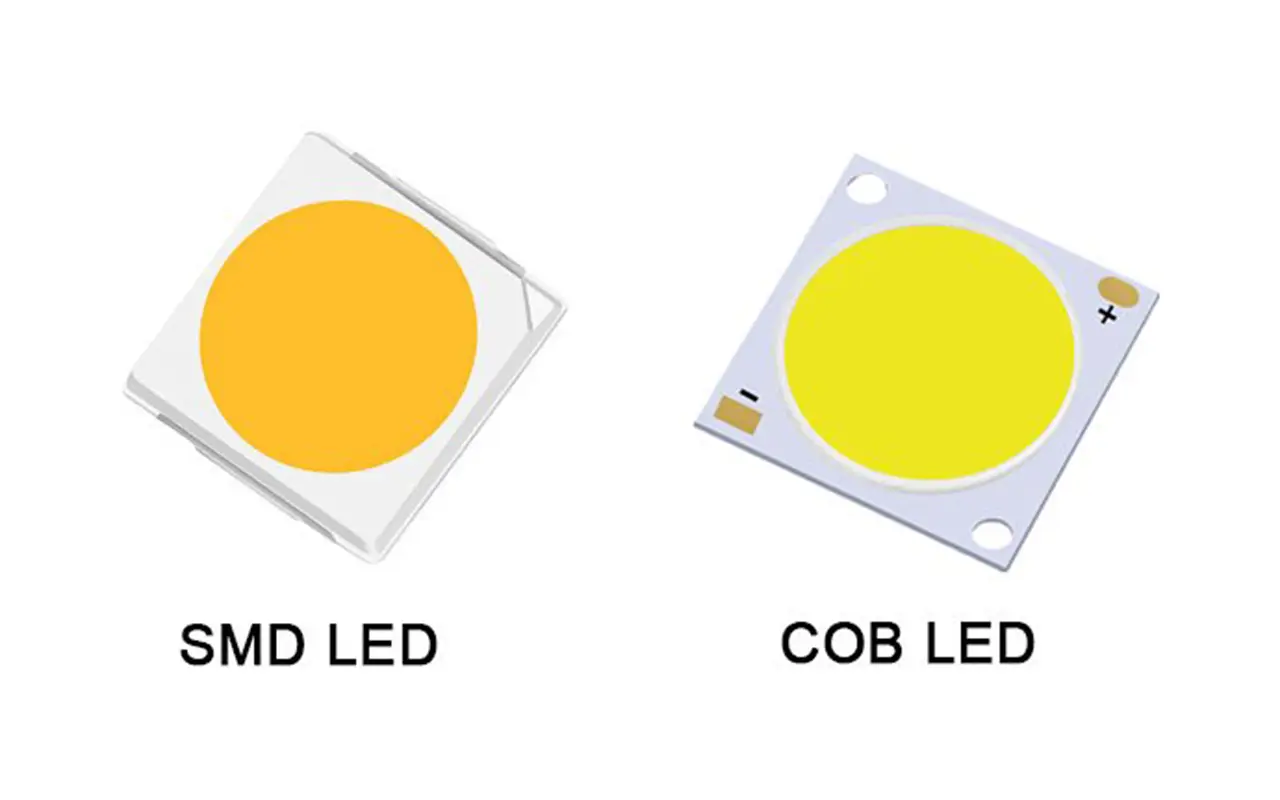

SMD LEDs vs. COB LEDs

Surface Mount Device (SMD) LEDs are known for their flexibility and efficiency, making them ideal for a wide range of lighting applications. These LEDs are mounted directly onto a circuit board, allowing for a more compact and versatile design. SMD LEDs can produce various colors and brightness levels, making them suitable for decorative and functional lighting. Their ability to be arranged in different configurations enables intricate designs and dynamic lighting effects, making them popular in architectural lighting, signage, and interior decoration.

On the other hand, Chip On Board (COB) LEDs offer a higher lumen density and more uniform light output. This is achieved by mounting multiple LED chips closely together on a single substrate, which acts as a single light source. COB technology results in a brighter and more concentrated light, making it ideal for applications requiring high brightness and consistent illumination, such as commercial signage, high-impact displays, and industrial lighting. COB LEDs are also known for their excellent thermal performance, which enhances their reliability and lifespan.

High-Quality vs. Low-Quality LED Chips

The quality of LED chips plays a crucial role in determining the brightness and overall performance of LED Neon Flex. High-quality LED chips are manufactured using advanced materials and processes, ensuring superior light output, excellent color consistency, and a longer lifespan. These chips efficiently convert electrical energy into light, minimizing energy loss and heat generation. As a result, high-quality LED chips provide a brighter and more reliable light source, enhancing the visual appeal and functionality of LED Neon Flex installations.

In contrast, low-quality LED chips often suffer from poor thermal management and inferior materials, leading to dimmer light, color variations, and shorter lifespans. These chips generate more heat, accelerating degradation and resulting in frequent replacements and higher maintenance costs. High-quality LED chips ensure consistent brightness, better performance, and long-term cost savings.

How Chip Quality Impacts Brightness

Performance Differences

High-quality LED chips provide consistent and reliable brightness by efficiently converting electrical energy into light. This efficiency minimizes energy loss and heat generation, ensuring the LEDs operate at optimal brightness levels. High-quality chips also exhibit better thermal management, reducing the risk of overheating and brightness degradation over time. This results in a stable and long-lasting light output that enhances the overall performance of LED Neon Flex installations.

Low-quality LED chips, on the other hand, often need help to maintain consistent brightness levels. These chips tend to have higher energy loss and generate more heat, which can lead to reduced light output and shorter lifespans. The inconsistent performance of low-quality LED chips can result in flickering, dimming, and other issues that negatively impact the effectiveness of LED Neon Flex lighting.

Longevity and Consistent Output

Premium LED chips are designed to maintain their brightness over extended periods, offering consistent illumination without significant lumen depreciation. This longevity translates to lower maintenance costs and sustained performance, ensuring LED Neon Flex installations remain bright and reliable for years. The durable construction and advanced materials used in high-quality LED chips contribute to their ability to withstand various environmental factors and maintain optimal performance.

In contrast, low-quality LED chips may experience rapid lumen depreciation, leading to noticeable decreases in brightness over time. These chips are more susceptible to environmental stresses, such as temperature fluctuations and humidity, which can accelerate their degradation and shorten their lifespan. By choosing high-quality LED chips, you can ensure that your LED Neon Flex installations deliver consistent brightness and reliable performance, reducing the need for frequent replacements and maintenance.

Power Supply and Voltage

Choosing the Right Power Supply

Wattage and Amperage Considerations

Selecting the right power supply is crucial for achieving optimal brightness in LED Neon Flex. The power supply must match the wattage and amperage requirements of the LEDs to ensure they operate efficiently. Wattage measures the total power consumption, while amperage indicates the current supplied to the LEDs. Providing insufficient power can lead to dim lighting, whereas excessive power can result in energy wastage and potential overheating.

When choosing a power supply, it’s essential to consider the total wattage and amperage required by your LED Neon Flex installation. This involves calculating the power needs based on the length and type of LED strips. Ensuring the power supply can handle the total load with a slight margin for safety helps maintain consistent brightness and prevents LED damage.

Matching Power Supply with LED Requirements

Properly matching the power supply to the LED Neon Flex specifications is vital for maintaining consistent brightness and preventing damage. A power supply with built-in voltage regulation and protection features ensures stable operation and extends the lifespan of the LEDs. Voltage regulation helps maintain a constant voltage level, protecting the LEDs from fluctuations that could cause flickering or dimming.

Using a high-quality power supply that meets your LED Neon Flex’s exact voltage and current requirements ensures optimal performance. This also includes selecting power supplies designed for LED applications, as they typically offer features like over-voltage, over-current, and short-circuit protection. These features provide additional safety and reliability, ensuring your LED Neon Flex installations operate at their best.

Effects of Voltage Fluctuations on Brightness

Common Voltage Issues

Voltage fluctuations can significantly impact the brightness of LED Neon Flex. Over-voltage can cause excessive heat generation, leading to potential burnout of the LED chips. Conversely, under-voltage results in dimmer light output and flickering. These fluctuations can compromise the performance and lifespan of the LEDs, making it essential to address voltage stability.

Common voltage issues include power surges, drops in voltage, and inconsistent power supply. These issues can be caused by various factors, such as electrical grid instability, faulty wiring, or using an inadequate power supply. Identifying and addressing these issues is crucial for maintaining the brightness and reliability of your LED Neon Flex installations.

Solutions to Voltage Problems

Using voltage regulators and stabilizers helps mitigate fluctuations, ensuring consistent brightness and prolonging the lifespan of the LED Neon Flex. Voltage regulators maintain a constant output voltage regardless of input variations, protecting the LEDs from over- and under-voltage conditions. Stabilizers can smooth out sudden spikes or drops in voltage, providing a stable power supply to the LEDs.

High-quality power supplies with built-in voltage regulation features also prevent voltage-related issues. These power supplies are designed to deliver consistent voltage and current, ensuring optimal performance and reliability of the LED Neon Flex. Regular maintenance and monitoring of the power supply system can further help identify and address voltage problems promptly, ensuring stable and efficient operation.

Dimm- und Steuerungssysteme

- PWM Dimming vs. Analog Dimming:Pulse Width Modulation (PWM) and analog dimming are primary techniques for controlling LED brightness. PWM dimming involves rapidly switching the LEDs on and off, while analog dimming adjusts the current flowing through the LEDs. Both methods have distinct advantages.

- Smart Control Systems:Smart control systems enable precise brightness adjustments through remote or automated controls, integrating with smart home technologies for enhanced functionality. Users can program lighting schedules, create dynamic scenes, and adjust brightness levels remotely.

Impact of Control Systems on Brightness

Control systems allow users to customize brightness levels to suit different environments and moods, enhancing the versatility of LED Neon Flex installations. Creating and saving custom lighting scenes optimizes lighting for various activities and occasions.

With advanced control systems, users can create dynamic lighting effects, adjust brightness in real time, and set automated schedules, optimizing the use of LED Neon Flex for various applications.

Wärme-Management

Importance of Heat Dissipation

Heat Sinks and Thermal Management

Effective heat dissipation is crucial for maintaining brightness and extending the lifespan of LED Neon Flex. Heat sinks and thermal management solutions help dissipate excess heat, preventing overheating and brightness reduction.

Impact of Overheating on Brightness

Overheating can lead to a significant drop in brightness and potential damage to the LED components. Proper thermal management ensures stable performance and consistent light output.

Common Heat Management Solutions

- Effective Cooling Techniques:Implementing effective cooling techniques, such as heat sinks and active cooling systems, helps manage the thermal load and maintain optimal operating temperatures for LED Neon Flex.

- Innovative Heat Management Technologies:Innovative technologies, such as graphene-based heat dissipation materials, offer advanced solutions for managing heat in LED lighting systems, ensuring sustained brightness and longevity.

Color Temperature and Brightness

Die Farbtemperatur verstehen

Color temperature affects the perceived brightness and ambiance of LED Neon Flex. Warm white LEDs create a cozy, inviting atmosphere, while cool white LEDs offer a bright, crisp light suitable for task-oriented environments.

The color temperature scale ranges from warm (2700K) to cool (6500K) tones. Warm temperatures produce a yellowish hue, while cool temperatures produce a bluish tint, influencing LED Neon Flex’s visual impact and functionality.

How Color Temperature Affects Perceived Brightness

Color temperature influences mood and perception. Warmer tones are often associated with relaxation, while cooler tones promote alertness and concentration. Selecting the right color temperature can enhance the desired atmosphere.

Considering the application and desired ambiance, best practices for selecting color temperature involve balancing aesthetic preferences with functional requirements to achieve optimal brightness and visual appeal.

Material and Build Quality

Importance of Using High-Quality Materials

Light Diffusion Properties

The material’s light diffusion properties affect the uniformity and brightness of the LED Neon Flex. High-quality diffusers provide even light distribution, enhancing overall brightness and visual consistency.

Material Durability and Performance

High-quality materials contribute to the durability and performance of LED Neon Flex. Superior materials ensure better light diffusion, resistance to environmental factors, and longevity.

Build Quality and Its Effect on Brightness

Manufacturing Precision

Precise manufacturing techniques ensure consistent light output and prevent issues such as light leakage and uneven brightness. High build quality is essential for achieving optimal performance.

Assembly Techniques

Effective assembly techniques contribute to LED Neon Flex’s structural integrity and reliability, ensuring stable brightness levels and long-term durability.

Installation and Environmental Factors

Optimal Installation Techniques

Placement and Orientation

Proper placement and orientation of LED Neon Flex impact brightness and coverage. Strategic installation enhances light distribution and minimizes shadows, achieving the desired illumination effect.

Securing and Supporting Structures

Using appropriate securing and supporting structures ensures stability and prevents damage, maintaining consistent brightness and performance over time.

Environmental Conditions Impacting Brightness

Environmental factors, such as exposure to sunlight and weather conditions, affect brightness and longevity. Selecting the right LED Neon Flex for outdoor or indoor use ensures optimal performance.

Temperature and humidity levels influence the performance of LED Neon Flex. Proper environmental considerations help maintain brightness and prevent condensation and thermal stress.

Maintenance and Longevity

How Longevity Affects Consistent Brightness

The lifespan of LED Neon Flex depends on factors like usage, maintenance, and environmental conditions. High-quality LEDs offer longer lifespans and sustained brightness, reducing the need for frequent replacements.

Implementing preventive measures, such as proper installation, effective heat management, and regular maintenance, enhances LED Neon Flex’s longevity and consistent brightness.

Routine Maintenance Tips for Sustaining Brightness

Regular cleaning and maintenance help sustain brightness and prevent the accumulation of dirt and debris, which can obstruct light output and degrade performance.

Routine inspections and troubleshooting ensure the early detection of issues, allowing for prompt repairs and maintenance to maintain consistent brightness.

Common Brightness Issues and Solutions

Identifying Common Brightness Problems

- Flickering and Inconsistent Output: Flickering and inconsistent output are common brightness issues resulting from power supply problems, poor connections, or faulty LED chips.

- Dimming and Loss of Brightness: Inadequate power supply, thermal issues, or aging components can cause dimming and loss of brightness. Identifying the root cause is essential for effective resolution.

Effective Solutions to Enhance Brightness

- Upgrading Components: Upgrading to higher quality components, such as LED chips and power supplies, can enhance brightness and performance, addressing common issues.

- Professional Troubleshooting Tips: Professional troubleshooting involves systematically diagnosing and resolving brightness issues, ensuring optimal performance and longevity of LED Neon Flex.

FAQs

Q: What is the primary factor determining the brightness of LED Neon Flex?

A: The primary factor determining the brightness of LED Neon Flex is the quality and efficiency of the LED chips used. High-quality LED chips produce more lumens per watt, resulting in brighter illumination.

Q: How does the power supply influence the brightness of LED Neon Flex?

A: The power supply plays a crucial role in LED brightness. Proper wattage and amperage ensure the LEDs receive consistent power, maintaining their brightness. An inadequate power supply can cause flickering or dimming.

Q: Can the installation process affect the brightness of LED Neon Flex?

A: Yes, installation techniques can impact brightness. Proper placement, orientation, and secure mounting help achieve optimal light distribution and prevent issues like shadows or leakage, ensuring consistent brightness.

Q: Why is heat dissipation important for maintaining LED brightness?

A: Effective heat dissipation prevents overheating, which can reduce LED brightness and lifespan. Heat sinks and thermal management solutions help maintain optimal operating temperatures, ensuring consistent light output.

Q: How does color temperature affect the perceived brightness of LED Neon Flex?

A: The color temperature measured in Kelvin affects how bright the light appears. Cool white (higher Kelvin) tends to appear brighter and is suitable for task lighting, while warm white (lower Kelvin) creates a softer, more inviting ambiance.

Q: What are common voltage issues that can impact LED brightness?

A: Voltage fluctuations, such as over- or under-voltage, can adversely affect LED brightness. Over-voltage can cause excessive heat and potential burnout, while under-voltage results in dimmer light and flickering.

Q: How do smart control systems enhance the brightness of LED Neon Flex?

A: Smart control systems allow for precise brightness adjustments and customization. They enable users to create dynamic lighting effects, adjust brightness in real time, and set automated schedules for optimal lighting conditions.

Q: What role do material and build quality play in LED Neon Flex brightness?

A: High-quality materials and precise manufacturing techniques ensure better light diffusion, durability, and resistance to environmental factors. Superior build quality prevents issues like light leakage and uneven brightness.

Q: How can regular maintenance sustain the brightness of LED Neon Flex?

A: Routine maintenance, such as cleaning and inspecting the LEDs, helps sustain brightness by preventing dirt and debris buildup. Regular troubleshooting ensures any issues are promptly addressed, maintaining consistent illumination.

Q: What future trends are expected to enhance LED Neon Flex brightness?

A: Innovations in LED technology, such as more efficient LED chips and advanced control systems, are expected to enhance brightness. Emerging applications like dynamic architectural lighting and interactive displays will drive further advancements.

Fazit

This article has explored the top factors affecting LED Neon Flex brightness, including chip quality, power supply, heat management, and installation techniques. For optimal brightness, choose high-quality components, ensure proper power supply and heat management, and follow best practices for installation and maintenance. Investing in advanced technologies and staying informed about industry trends helps future-proof your LED Neon Flex installations, ensuring sustained performance and brightness. Embracing new technologies and innovative solutions enhances LED Neon Flex’s brightness, efficiency, and versatility, unlocking new possibilities for creative and functional lighting applications.

Unitopeiner der führenden chinesischen Hersteller von LED-Leuchtbänder und LED Neon Flex, stands at the forefront of the industry with unparalleled expertise and top-quality products. If you have further questions or specific requirements, please Nehmen Sie Kontakt mit uns auf immediately. Our dedicated team is ready to assist you in finding the best lighting solutions to meet your needs, ensuring your projects shine with the brilliance they deserve.

Tom ist jetzt der Verkaufsleiter von Unitop (China) Co., Limited. Er war in der LED-Beleuchtung Industrie seit 2005. Er ist Experte für Vertrieb und Marketing sowie für Fabrikmanagement. Er mag Bodybuilding und ist außerdem ein verrückter Apple-Fan! Er ist ein fleißiger Kerl und liebt es, neue Dinge zu lernen und auszuprobieren.

E-Mail: tom@unitopledstrip.com WhatsApp: +86-18680307140

Hinterlasse einen Kommentar

An der Diskussion beteiligen?Hinterlasse uns deinen Kommentar!