Transform your space with the magic of LED strip lights! Our guide on connecting LED strip lights in series offers expert insights and practical tips to ensure your lighting project shines bright and functions flawlessly.

Successfully connecting LED strip lights in series requires understanding voltage dynamics, choosing compatible power supplies, and following precise installation steps.

This guide provides comprehensive, step-by-step instructions and essential safety measures to ensure your LED lighting project achieves optimal brightness and longevity. Dive into our detailed guide to discover innovative design ideas, troubleshoot common issues, and make informed decisions between series and parallel connections. Your journey to mastering LED strip lighting starts here!

Understanding the Basics of Series Connection for LED Strips

Diving deeper into the technical world of LED strip lighting, understanding the nuances of a series connection is crucial. When LEDs are connected in series, the same current flows through each strip, but the voltage is divided among them. This is akin to water flowing through a single pipeline with multiple taps; the pressure (voltage) drops as it travels further. The concept of voltage drop becomes significant over long distances, causing the LEDs at the far end of the strip to appear dimmer than those closer to the power source. To combat this, it’s vital to ensure that all your LED strips have compatible specifications. Mismatched voltage and wattage can lead to inefficient lighting or even damage to the strips. Equally important is choosing a power supply that can accommodate the total voltage requirement of all your strips. It’s a balancing act – ensuring that the sum of the voltages across each LED strip does not exceed the power supply’s capacity yet is sufficient to illuminate each LED effectively.

Comprehensive Guide to Installing LED Strips in Series

When installing LED strips in series, several additional factors need to be considered to ensure a successful and efficient setup:

- Wire Gauge and Length: Select the appropriate wire gauge for your LED strip installation. Thicker wires (lower gauge number) are needed for longer runs to minimize voltage drop, which can cause dimming and inconsistent lighting.

- Heat Management: LEDs generate heat, and poor heat management can significantly shorten their lifespan. Ensure that your LED strips are mounted on a surface that helps dissipate heat, like a metal heat sink or a surface with good thermal conductivity.

- Power Supply Placement: Place your power supply close to the LED strips to reduce voltage drop. This is especially important for longer strips or when multiple strips are connected in series.

- Dimming and Control Systems: If you plan to use dimmers or controllers, ensure they are compatible with your LED strips. Check for the required input and output voltage and current specifications.

- Ambient Conditions: Consider the environmental conditions where the LED strips will be used. If they are exposed to elements like moisture or high humidity, use waterproof LED strips and connections.

- Testing Before Permanent Installation: Before fully installing the strips, connect and test all components to ensure everything works correctly. This step helps identify any faulty segments or connection issues.

- Securing LED Strips: Use appropriate mounting clips or adhesive backing to secure the LED strips firmly. Avoid overstretching the strips during installation to prevent damage.

- Precauciones de seguridad: Always disconnect the power supply before making any changes or adjustments to avoid the risk of electric shock.

- Mantenimiento: Regularly check your LED strips for any signs of damage or wear. Clean them gently to prevent dust accumulation, which can affect lighting quality.

- Professional Consultation: If unsure about the installation process, particularly for complex setups, consider consulting a professional electrician or lighting expert. This can help prevent costly mistakes and ensure a safe installation.

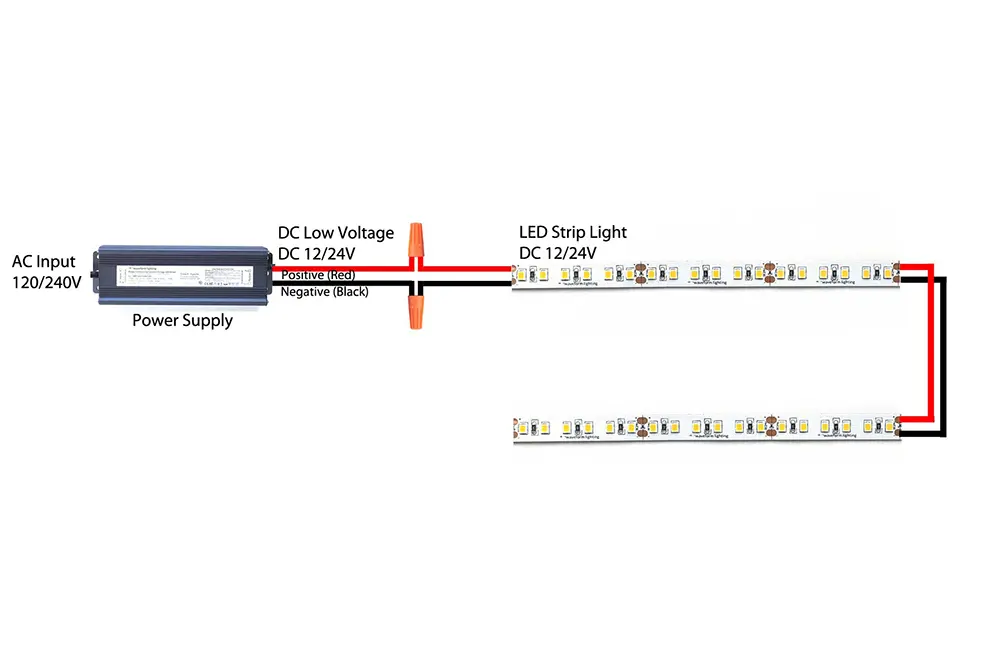

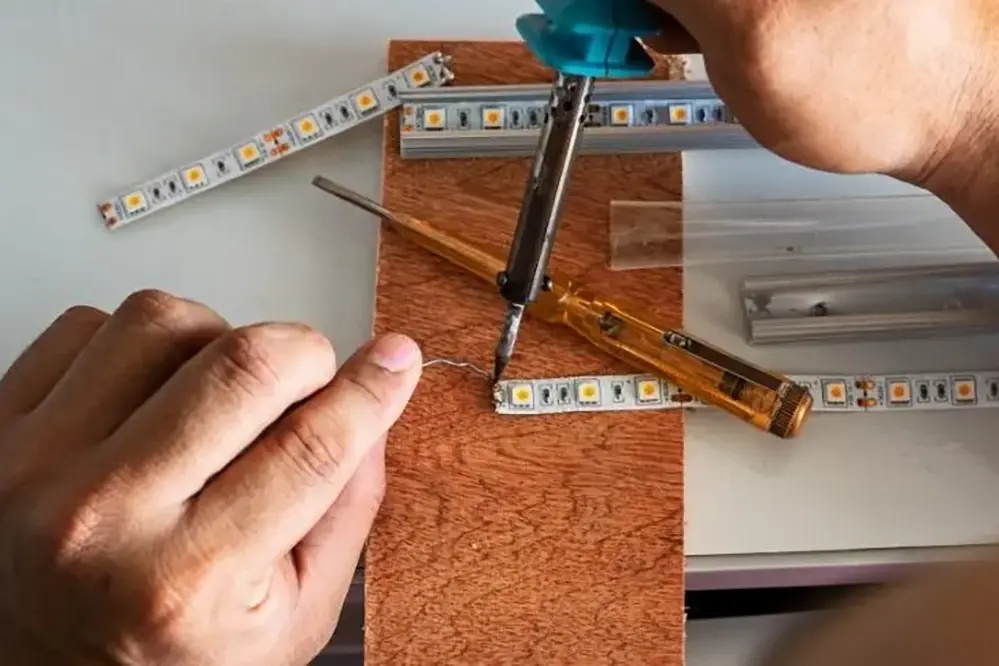

The installation process of LED strip lights in series is more than just connecting wires; it’s about ensuring longevity and performance. Begin by calculating the total voltage of your LED setup and the power requirements. This step is crucial to avoid overloading your power supply. Next, gather the right tools. For shorter connections, solderless connectors are a practical choice, providing a hassle-free installation. However, for longer or more permanent installations, soldering provides a more secure connection. Pay careful attention to the alignment of positive and negative terminals during installation – a common pitfall that can lead to short circuits or uneven lighting. Utilizing diagrams or images can significantly aid in this process, providing a visual guide to ensure correct installation. It’s worth noting that a misstep in installation could not only lead to uneven lighting but also potentially damage the LED strips. Therefore, precision and attention to detail are key.

Solving Common Issues in Series LED Strip Connections

Addressing common issues in series connections of LED strip lights primarily revolves around tackling voltage drop. The first step is to ensure that you’re using high-quality LED strips. Lower-quality strips often have less consistent manufacturing standards, which can exacerbate voltage drop issues. Regular maintenance and visual inspections play a pivotal role in the early detection of problems like dimming or uneven lighting. If these issues persist despite proper installation and quality strips, it might be wise to consult with a lighting professional or consider an alternative setup, such as a parallel connection. A parallel setup, while more complex in wiring, can provide a more consistent voltage to each LED strip, thus eliminating issues of dimming and voltage drop. It’s about finding the right balance for your specific lighting needs and space.

Aplicaciones creativas e ideas de diseño para tiras LED conectadas en serie

Expanding the creative potential of series-connected LED strips opens a world of design possibilities. These versatile lighting solutions can be used in various settings to create both ambiance and functional illumination. In residential spaces, they can be used for mood lighting, under-bed lighting, or as accent lights in living rooms, adding a warm and inviting glow. In kitchens, series-connected LED strips under cabinets not only provide excellent task lighting but also enhance the overall aesthetics of the space.

In commercial settings, these LED strips can be used to create stunning visual displays. Retail stores can use them to highlight products or create dynamic window displays, while restaurants and bars can set the right mood and ambiance. In galleries and museums, LED strips can accentuate artwork, making colors more vibrant and details more pronounced.

The versatility of LED strips also extends to outdoor applications. They can be used to light up pathways, gardens, or patios, creating a cozy and welcoming outdoor environment. The key to successful application lies in understanding the specific lighting needs of a space and creatively integrating LED strips to meet those needs.

Series vs. Parallel LED Strip Connections: Making the Right Choice

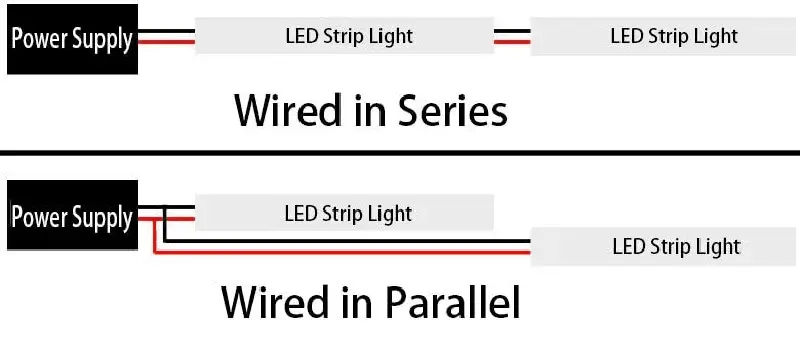

The decision between series and parallel connections for LED strip lights hinges on the specific requirements of your project. Series connections are straightforward and cost-effective, making them suitable for smaller projects or where uniform brightness is not a critical factor. They are ideal for applications like highlighting a piece of art or creating a single run of lighting in a small room.

Parallel connections, while more complex and potentially costlier, offer significant advantages in larger installations. They are particularly useful in settings where uniform brightness is crucial, such as in large retail spaces or offices. In these applications, the consistent voltage of parallel connections ensures that each LED strip maintains the same brightness level, which is essential for creating a professional and appealing lighting environment.

Clarifying Electrical Terms: Series and Parallel Explained

Understanding the distinction between series and parallel connections in LED lighting is crucial for any successful installation. In a series connection, the current passes through each LED strip one after the other. This configuration is simple but can lead to a voltage drop across the LED strips, especially over longer distances. In contrast, a parallel connection allows each LED strip to receive the same voltage directly from the power source. This setup maintains consistent brightness across all strips but requires more intricate wiring and planning.

Tailoring Connections for Various LED Strip Models

Each LED strip model comes with its unique set of requirements and characteristics. High-power LED strips, such as the LumiBar Sunlike CRI98+, typically require robust drivers that can handle higher current and voltage levels. On the other hand, smaller, lower-power LED strips may be adequately powered by simpler, less expensive constant current sources. It’s crucial to match each LED strip with a compatible driver to ensure optimal performance and longevity.

Alternative Connection Methods and Useful Accessories

There are several innovative methods and accessories available for connecting LED strips to suit various installation needs. Gapless pin connectors offer a sleek, continuous look, ideal for applications where the appearance of the lighting is as important as its functionality. Jumper cord connectors provide the flexibility needed for installations that require bending around corners or following irregular surfaces. For more permanent and durable installations, soldering the connections can provide a robust solution.

Efficient Power Supply Management for Multiple LED Strips

Effective power supply management is a critical aspect of installing multiple LED strips. It is essential to ensure that the total wattage of the connected LED strips does not exceed the capacity of the power supply. This not only prevents potential overheating and damage but also ensures the longevity of both the power source and the LED strips. A conservative approach is to use only up to 80% of the power supply’s rated capacity, providing a buffer for safety and efficiency. This approach is particularly important in larger installations where the power requirements can be significant.

Conclusión

In conclusion, mastering LED strip light connections, whether in series or parallel, is essential for versatile and effective lighting solutions. Series connections suit shorter runs, while parallel connections are ideal for uniform brightness in larger areas.

Remember that expert guidance and high-quality products are key to success. Unitop, a premier manufacturer in China, stands at the forefront of the LED industry, offering an exceptional range of Tiras de luces LED y Flexo de neón LED, renowned for their quality and reliability. If you have any further questions or specific requirements, don’t hesitate to póngase en contacto con nosotros. Unitop’s expertise in LED technology is unmatched, and we’re here to help you illuminate your world beautifully and efficiently. Contact us now to bring your lighting visions to life with confidence and professional support.

Tom es ahora el Director de Ventas de Unitop (China) Co., Limited. Ha estado en el Iluminación LED industria desde 2005. Es experto en ventas y marketing, y en gestión de fábricas. Le gusta el culturismo, ¡y también es un fan loco de Apple! Es un tipo muy trabajador y le encanta aprender y probar cosas nuevas.

Correo electrónico: tom@unitopledstrip.com WhatsApp: +86-18680307140

Dejar un comentario

¿Quieres unirte a la conversación?Siéntete libre de contribuir!