Considering lighting up your fabric projects with LEDs? Whether for fashion enhancements or home decor, understanding the safety of integrating LED lights with various fabrics is crucial.

LED lights can be safely used on fabrics, which involves careful consideration of insulation, heat management, fabric type, and the use of low-voltage LEDs to prevent risks like fire or fabric damage.

Discover how to creatively and safely incorporate LED lights into your fabric projects. From selecting the right materials to proper installation techniques, this guide covers everything you need to know.

Understanding the Risks of LEDs on Fabric

Integrating LED lights into fabric projects isn’t just about the aesthetic upgrade—it’s also about understanding and mitigating potential risks. This section delves deeper into the primary concerns associated with using LEDs on fabric, such as heat generation, electrical safety, and material compatibility. By understanding these risks, crafters and designers can safely harness the benefits of LEDs in their fabric projects.

Heat Generation

While LEDs are celebrated for their energy efficiency, they still generate heat during operation. This heat emission might be minimal compared to traditional lighting solutions, but it becomes a significant concern when LEDs are enclosed within or attached directly to fabric. The trapped heat could elevate temperatures to the point of damaging the fabric, which might lead to discoloration, melting, or even fire, particularly with heat-sensitive or highly flammable materials. For instance, using LEDs on lightweight synthetic fabrics, which often have lower melting points, requires careful planning and testing to ensure safety.

To mitigate this, it’s advisable to:

- Choose LEDs specifically designed for low heat output.

- Implement spacing strategies that allow heat to dissipate efficiently.

- Consider using LED enclosures that enhance heat dissipation.

Electrical Safety

The use of low-voltage LEDs in fabric projects is crucial for minimizing risks such as electric shocks or short circuits. These LEDs are typically safer to handle and integrate into textiles compared to their high-voltage counterparts. Moreover, ensuring that all electrical components are properly insulated is fundamental to preventing electrical mishaps. This includes securing all connections and covering exposed wires with appropriate insulating materials.

Best practices for electrical safety include:

- Using battery-operated LEDs where possible reduces the need for direct electrical connections to power sources.

- Regularly inspecting the wiring and connections for wear and tear or potential breaches in insulation.

- Employing connectors and junctions that are designed for safe use with textiles.

Material Safety

Not all fabrics are suitable for use with LED lighting. The selection of fabric is as crucial as the selection of the LEDs themselves. Materials that are less flammable and more resistant to heat should be prioritized to reduce the risk of fire and damage. For example, polyester and treated cotton are generally safer than more flammable materials like nylon or untreated wool. These safer fabrics typically have higher melting points and are less likely to ignite, which makes them ideal for projects involving LEDs.

When choosing fabrics, consider:

- The fabric’s flammability rating should be as low as possible.

- The heat resistance properties of the material, ensure it can withstand the temperatures generated by the LEDs without degrading.

- The texture and density of the fabric can affect both the visual outcome and the safety of the LED integration.

In summary, while the integration of LEDs into fabric projects offers a vast array of creative possibilities, it necessitates a thorough understanding of the risks involved. Addressing these risks through careful selection of LEDs and fabrics, and adhering to safety practices, ensures that your illuminated fabric projects are not only stunning but also safe.

Step-by-Step Installation Guide

A well-planned and carefully executed installation is key to safely incorporating LED lights into fabric projects. This step-by-step guide ensures that both novice and experienced crafters can achieve professional results without compromising on safety.

Planning and Design

Effective planning is crucial in avoiding many common issues with fabric and LED integrations, such as uneven lighting and potential overheating. Start by sketching your design on paper, including the exact positions where LEDs will be placed. This visual blueprint helps in visualizing the result and aids in the even distribution of lights. Consider the purpose of the illumination—whether for aesthetic enhancement or functional visibility—to determine the density and color of the LEDs. Also, factor in the flexibility of the fabric and how it will be used (e.g., wearable technology, decorative pillows), as these will influence the placement and type of LEDs used.

Tips for Effective Planning:

- Use graph paper to plot the exact positions of LEDs for precision.

- If designing wearable tech, consider the movement of the fabric and place LEDs at flex points for durability.

Preparation

The preparation phase involves making the fabric ready for LED integration. Reinforce the areas where LEDs will be attached, especially if the fabric is delicate or prone to tearing. This can be done using interfacing or similar stabilizing material, which not only supports the fabric but also ensures that the weight and pull of the LEDs do not distort the fabric’s natural drape.

Fabric Reinforcement Techniques:

- Iron-on interfacing for quick and easy reinforcement.

- Sewing a double layer of fabric in areas where LEDs will be attached for added strength.

Attachment

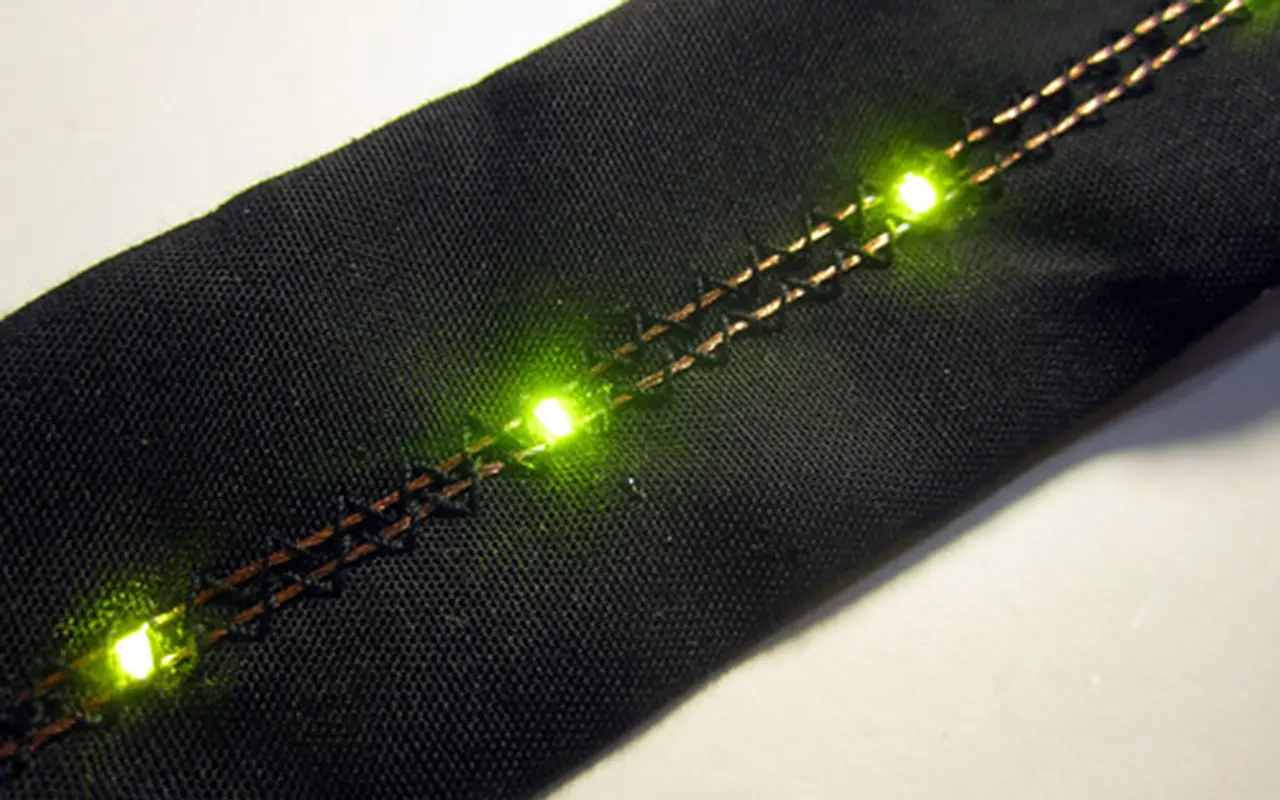

The method of attaching LEDs to fabric can greatly affect both the final appearance and functionality of the project. For most projects, sewing with conductive thread is ideal as it integrates the electrical connections within the fabric itself, making the project more durable and washable. Alternatively, non-conductive fabric glues can be used for temporary installations or for fabrics that cannot be sewn. Avoid using methods like staples or heavy sewing that might damage the LED wiring.

Attachment Methods:

- Conductive thread for creating electrical pathways while securing LEDs.

- Fabric glue for temporary placements or non-sewable fabrics.

Wiring and Insulation

Proper wiring and insulation are critical to ensuring safety and functionality. Use heat-shrink tubing or high-quality electrical tape to insulate all exposed wires and connections. This not only prevents short circuits but also protects the wires from wear and tear that could occur during the use of the fabric item.

Insulation Tips:

- Choose heat-shrink tubing that matches the wire size for a snug fit and better protection.

- Routinely check and replace electrical tape or tubing if it shows signs of wear.

Testing and Adjustments

Before the final implementation, thoroughly test the LED setup. Power on the LEDs to check for even lighting and inspect for any hot spots or dim areas. Adjust the placement as needed and ensure all electrical connections are secure and well-insulated. This testing phase is crucial to not only ensure the visual appeal but also the safe operation of the LEDs.

Testing Procedures:

- Use a multimeter to check for consistent voltage across all LEDs to ensure even lighting.

- Perform a “burn-in” test by running the LEDs for an extended period to detect any potential overheating issues.

- By following these detailed steps, you can safely and effectively incorporate LED lighting into any fabric project, enhancing both its aesthetic and functional qualities.

Maintenance and Safety Tips

Proper maintenance and adherence to safety guidelines are crucial for ensuring the longevity and safe use of fabric projects integrated with LED lights. Here are some essential tips for cleaning, care, regular inspections, and safety precautions to help maintain the quality and safety of your LED-enhanced fabric items.

Cleaning and Care

Handling fabrics embedded with LED lights requires careful cleaning to avoid damaging the electronic components. Here’s how you can keep these items clean and functional:

- Hand Washing: Gently hand wash the fabric around the LEDs using mild soap and lukewarm water, avoiding direct contact with the electronics. Pat dry without wringing to minimize stress on the wires and connections.

- Spot Cleaning: For minor stains or dirt, use a soft cloth or sponge lightly dampened with a mild detergent to clean the area around the LEDs.

- Dry Cleaning: If the fabric permits, consider professional dry cleaning. Inform the cleaners about the electronic components to ensure they use processes that won’t damage the lights.

Regular Inspections

Routine checks are essential to catch and resolve any issues before they lead to malfunction or accidents:

- Visual Inspections: Periodically examine the fabric for any visible signs of damage such as frayed wires, loose connections, or exposed electronics. Check that all LEDs are securely attached and that there is no peeling or detachment of insulated coverings.

- Functional Tests: Turn on the LEDs regularly to ensure they all light up uniformly and there are no flickering or dimming sections that could indicate electrical issues.

- Connection Checks: Ensure that all connections are tight and secure, especially after cleaning or handling the fabric.

Safety Precautions

Ensuring safety while using and storing your LED-enhanced fabrics can prevent accidents and extend the lifespan of the items:

- Power Management: Always turn off and disconnect the fabric from power sources when not in use. This helps to prevent overheating and conserves energy.

- Storage: Store LED-enhanced fabrics in a cool, dry place away from direct sunlight, which can degrade both the fabric and electronic components. Avoid folding the fabric in areas where LEDs are installed to prevent damaging the lights and wires.

- Supervised Use: When using LED-enhanced fabrics, especially in environments such as children’s rooms or public spaces, ensure they are always monitored. This reduces the risk of overheating and electrical hazards.

By following these maintenance and safety tips, you can enjoy the beauty and functionality of LED-integrated fabrics safely and for an extended period. Regular care and attention will keep your fabric looking great and functioning perfectly, adding a touch of light and creativity to your environment.

Creative Applications of LEDs in Fabric Projects

LEDs offer versatile and innovative opportunities to enhance fabric-based projects across fashion, home decor, and special occasions. Let’s explore how these tiny lights can transform ordinary materials into enchanting pieces.

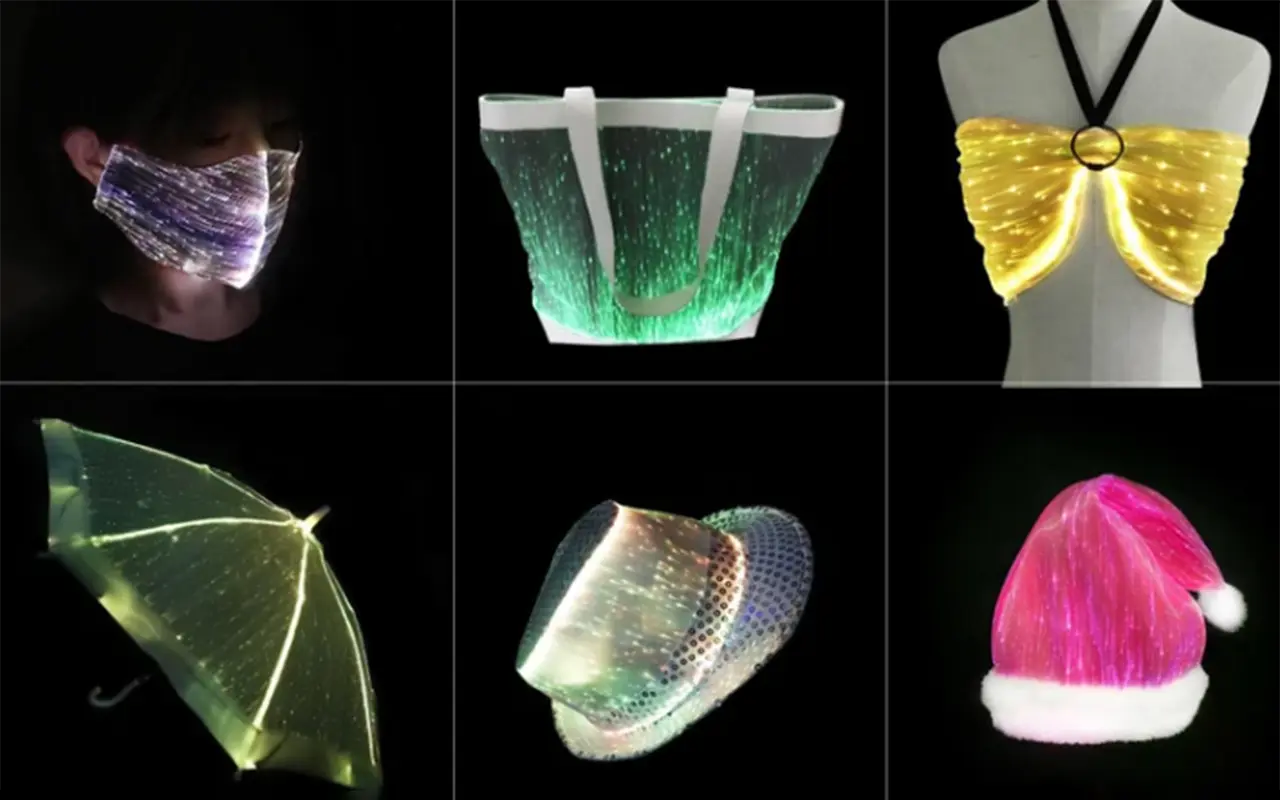

Fashion

Integrating LEDs into clothing and accessories opens up a world of dynamic and interactive fashion possibilities.

Designers can create garments that light up the runway with patterns that change colors or intensify in brightness in response to sounds or movements. Among the ways to incorporate LEDs into fashion, interactive costumes are perfect for performances or interactive events. These costumes with embedded LEDs can respond to environmental inputs like music or movement, adding a layer of engagement to the wearer’s presence.

Additionally, for those who enjoy nighttime activities such as biking or jogging, integrating LEDs into clothing can provide increased visibility, blending safety with style.

Another innovative approach is high fashion with a tech twist, where designers incorporate LEDs into haute couture pieces to make a bold statement in fashion shows or avant-garde gatherings.

Home Decor

LED-enhanced fabrics offer more than just wearable technology; they can significantly transform the ambiance of any living space.

By sewing LEDs into curtains, pillow covers, or furniture throws, you can create a unique and customizable lighting atmosphere that elevates room decor. For example, integrating LEDs into curtain fabrics can produce soft lighting that adapts to the time of day or specific room themes, enhancing both mood and functionality.

Additionally, dynamic pillow covers that change colors through remote control or smart home systems introduce an interactive and fun element to living room or bedroom environments.

Moreover, using LED strips behind fabric panels can generate artistic displays, turning these panels into striking focal points within a room.

Special Occasions

LEDs can significantly enhance the decor of special events, offering functional lighting while also accentuating the thematic elements of the occasion.

At weddings, for instance, LEDs sewn into fabrics for backdrops or centerpieces can create a fairy-tale atmosphere with twinkling lights that mimic stars, adding a magical touch to the celebration.

For festive holidays like Christmas or Halloween, integrating LEDs into table runners, banners, or party hats can brighten celebrations and add an extra layer of festivity.

Additionally, using LED-lit fabrics for event signage not only draws attention but also directs guests effectively, combining both decorative appeal and practical functionality.

FAQs

Q: What is the best way to power LED lights on fabric for wearable technology?

A: For wearable fabric projects, battery-operated LEDs are ideal as they are lightweight and minimize the risk of electrical hazards. They also provide greater flexibility and freedom of movement.

Q: Can I machine wash fabric with integrated LED lights?

A: It is not recommended to machine wash fabric with integrated LEDs. Instead, hand wash or spot clean around the LEDs carefully to avoid damaging the electronics. Always check the manufacturer’s care instructions.

Q: Are LED lights on fabric safe to use around children?

A: Yes, LED lights can be safe around children when properly installed and insulated. Always ensure that LED setups in children’s areas are battery-operated and securely attached to the fabric to prevent accidental ingestion or entanglement.

Q: How can I ensure the LED lights do not overheat when embedded in fabric?

A: To prevent overheating, choose LEDs specifically designed for low heat output, ensure adequate spacing between each LED, and select fabrics that dissipate heat effectively. Testing the setup for heat distribution before permanent installation is also crucial.

Q: What types of fabric are best for projects using LED lights?

A: Fabrics that are durable and heat-resistant, such as polyester or thick cotton blends, work best with LED lights. Avoid very thin or highly flammable materials like nylon or untreated wool.

Q: Can I use LED strip lights on any type of fabric?

A: LED strip lights can be used on many types of fabrics, but it’s important to ensure that the fabric can handle the weight and heat of the lights. Fabrics with a tighter weave or higher heat resistance are preferable.

Q: Why do my new LED strip lights flicker?

A: Flickering can occur due to incompatible parts, poor connections, or an incorrect power supply. Ensure that all connections are secure and that the power supply matches the LED specifications.

Q: Can flickering LED strip lights cause any harm?

A: While generally not harmful, continuous flickering can reduce the lifespan of LEDs and might indicate underlying electrical issues that should be addressed to avoid potential hazards.

Q: How long do LED lights last when used on fabrics?

A: LED lights typically have a long lifespan, often lasting up to 50,000 hours depending on usage and quality. Proper installation and maintenance can help maximize their lifespan even when used on fabrics.

Q: Is it safe to leave LED-lit fabrics switched on overnight?

A: It’s best to avoid leaving LED-lit fabrics unattended for long periods, including overnight. This minimizes the risk of electrical issues and extends the life of the LEDs.

Conclusion

Incorporating LED lights with fabrics not only merges functionality with creativity but also opens up a myriad of innovative applications. Whether it’s making a fashion statement, enhancing home decor, or adding a sparkling touch to special occasions, LEDs bring a magical quality to ordinary fabrics. By adhering to safety guidelines and choosing the right materials and setups, you can confidently explore the realm of fabric and LED integration. Embrace this luminous technology and let your creative projects shine with both safety and style.

Exploring the integration of LED lights with fabrics opens up endless creative possibilities. As a leader in this innovative field, Unitop, one of China’s top manufacturers of LED strip lights and LED neon flex provides top-quality, reliable products. If you have any questions or specific needs, contact Unitop immediately to elevate your projects with expert advice and cutting-edge LED solutions. Illuminate your designs with confidence and creativity—reach out to Unitop today!

Related Posts

Tom is now the Sales Manager of Unitop (China) Co., Limited. He has been in the LED Lighting industry ever since 2005. He is an expert in sales & marketing, and factory management. He likes bodybuilding, and he is also a crazy Apple Fan! He is a hard-working guy and loves to learn and try new things.

Email: tom@unitopledstrip.com WhatsApp: +86-18680307140

Leave a Reply

Want to join the discussion?Feel free to contribute!