Have you ever wondered how every LED light you come across exudes a consistent glow, unfazed by the erratic nature inherent to electronics? The answer lies in a meticulous process known as LED binning, a behind-the-scenes hero ensuring that each LED light shines bright and consistent, ready to take on the world of illumination.

I am Tom, and having been immersed in the LED industry since 2005, I’ve witnessed the evolution of LED technology and the pivotal role that LED binning plays in that narrative. With years of hands-on experience and a deep-seated knowledge of the LED domain, I am here to illuminate the nuances of LED binning.

As we navigate the intricacies of LED binning in the forthcoming content, you’ll uncover the science and art behind sorting LEDs based on color, brightness, and voltage. From understanding the necessity of LED binning to exploring the process step-by-step and delving into the challenges, this blog post is designed to illuminate the path for curious minds.

So, are you ready to delve into the world where science meets art to create a spectacle of light? Let’s dive right in!

Demystifying LED Binning

Definition and elucidation of LED Binning

LED binning is a meticulous exercise in sorting and grouping LEDs based on specific attributes like color, brightness, and occasionally, voltage. It’s a narrative of precision, where each LED is evaluated and grouped with its counterparts sharing similar characteristics. This process transcends the realm of mere sorting; it is a quest for uniformity and quality, ensuring that each LED delivers a performance that resonates with the industry’s benchmarks and the consumers’ expectations. It’s about orchestrating a symphony of light where each LED, akin to a musician, hits the right note, rendering a luminous, consistent, and captivating melody.

The imperative of LED Binning for maintaining consistency and quality

LED Binning isn’t just a process; it’s a pledge to uphold the standards of quality and consistency. It’s about mitigating the natural variances of mass production, ensuring that what shines through is a cohesive aura of light devoid of discordant hues or erratic brightness. It’s an endeavor to render an ambiance predictable in its allure, be it the warm embrace of a cozy cafe or the vibrant buzz of a contemporary workspace. The narrative of LED binning is about building trust, one LED at a time, ensuring that the spectral journey they offer is seamless and reliable.Click here to add your own text

The Anatomy of the Binning Process

Classifying LEDs based on color, brightness, and voltage

The odyssey of LED binning commences with a detailed classification, a venture into the heart of each LED to understand its color, brightness, and voltage. It’s a dialogue between the metrics and the aesthetic, ensuring that what emerges is a group of LEDs ready to render a harmonious spectacle of light. The process is akin to a meticulous choreographer ensuring each performer is in sync, ready to dazzle the stage with a cohesive and captivating performance.

An overview of methods and technologies harnessed in LED binning

The domain of LED binning is embellished with a suite of technologies and methods, each with its unique narrative. Spectrophotometry, a realm where light and matter dance to the rhythm of metrics, plays a pivotal role in evaluating the spectral characteristics of LEDs. The narrative doesn’t end here; visual inspections and automated binning are the vigilant custodians, ensuring each LED is categorized with a precision that echoes the meticulousness of a jeweler evaluating a gemstone’s facets. It’s a journey of accuracy, ensuring that the narrative of light each LED is set to narrate is compelling and consistent.

The Binning Landscape: Key Areas

The landscape of LED binning is a diverse tapestry, with each area holding its unique narrative. Be it color binning, where the hue is the hero, or luminous flux binning, where brightness takes center stage, each domain is a quest for perfection. The narrative extends to voltage binning and temperature binning, realms where the temperament and voltage of LEDs are meticulously evaluated to ensure a reliable and spectacular performance.

The Engine Behind LED Binning: How Does It Work?

Venturing into the engine room of LED binning is akin to peering into the meticulous preparations before a grand orchestra. The narrative commences with sorting the LEDs based on voltage and brightness, a detailed exercise ensuring each LED is in harmony with its designated specifications. The journey doesn’t end here; it’s about quality control, a vigilant guardian ensuring each LED is ready to render a performance that would enchant the audiences with its consistency and quality. It’s about orchestrating a narrative of light that is not merely spectacular but reliable, ensuring a luminous journey that resonates with the essence of quality and the promise of consistency.

Why Binning Holds the Reins: Its Necessity

The narrative of binning in the LED domain is a testament to the pursuit of perfection. It’s about orchestrating a spectacle of light that is not just visually enthralling but embodies a non-negotiable consistency and quality. Binning is the unseen maestro, ensuring that the luminous output from each LED is a harmonic note in a grand visual symphony. The unseen labor, the meticulous sorting and grouping, ensures the world of LED lights is a realm of reliability and uniformity. Without the process of binning, the narrative of LEDs would be one of erratic luminosity and discordant color hues, a far cry from the captivating allure it holds today.

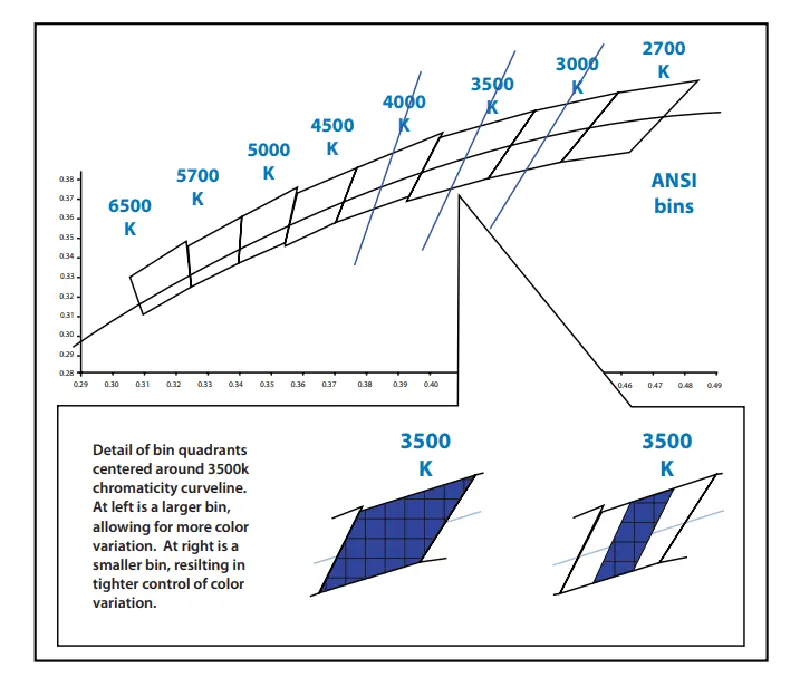

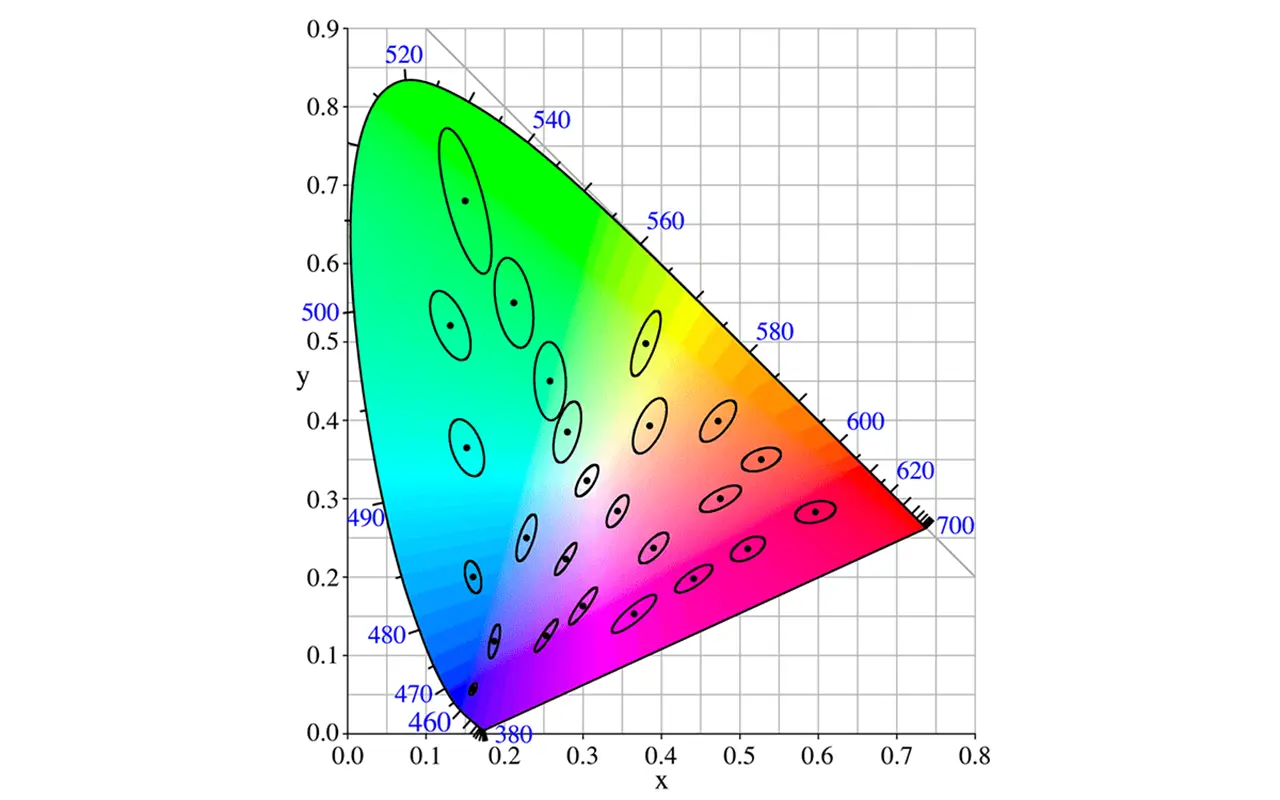

Diving into Details: The CIE 1931 Diagram

Embarking on the voyage of understanding LED binning, one encounters the compass of the CIE 1931 Diagram. It’s a graphical representation that transcends the visible, delving into the spectrum of colors in a way that quantifies the visual allure of LEDs. The diagram is the lexicon through which the narrative of color representation in LED binning is articulated. It lays down the coordinates the rules of engagement, ensuring the dance of colors in the LED domain is one of precision, consistency, and allure. Through the lens of the CIE 1931 Diagram, the narrative of color in LED binning unfolds, embodying a level of sophistication and accuracy that is pivotal in the LED industry.

| SDCM | Visibility |

|---|---|

| 1 | Almost impossible to see a difference |

| 2 | Differences seen through measuring instruments |

| 3 | Less color differences visible |

| 4 | Visible color differences |

| 5 | Clear color differences |

The Dance of Colors: LED Binning with MacAdam Ellipses

The narrative of MacAdam Ellipses in the realm of LED binning is akin to the rhythm of a dance. It’s the framework that dictates the color variations, ensuring synchrony and harmony in the luminous output. MacAdam Ellipses are about the subtleties, the slight color variations that could differentiate between a captivating visual experience and an ordinary one. They are the choreographers ensuring the color performance of LEDs is a mesmerizing dance. This spectacle leaves an indelible imprint on the visual canvas.

The Bounty of LED Binning

Improved Color Consistency

The pursuit of color consistency in LED binning is a narrative of visual harmony. It’s about ensuring the color that bathes your space is steady, devoid of flickers or unexpected shifts in hue. It’s a pursuit that allows, whether you are basking in the warm glow of a bedside lamp or the vibrant light of a chandelier, the color remains true, enhancing the aesthetic appeal and the reliability of LED products.

Ramp-up in Efficiency

Efficiency is the melody that resonates through the process of LED binning. It’s about orchestrating a performance where each LED is a note that hits the right chord regarding brightness and energy consumption. The process ensures that the LEDs are not just luminous marvels but embodiments of energy efficiency. This narrative is increasingly pivotal in a world leaning towards sustainable solutions.

Quality Control Mastery

Quality Control in LED binning is the final act, ensuring each LED is a performer ready to enchant with its luminous output. The meticulous inspection and fine-tuning ensure each LED is devoid of any imperfections that could mar its performance or longevity. It’s about ensuring that what reaches the consumer is nothing short of perfection, a narrative of reliability and quality.

Exploring the Types of LED Binning

The spectrum of LED binning is a narrative of diversity, each type holding its unique essence and significance.

Color Binning

In the narrative of LED binning, Color Binning is the artist, ensuring the palette of colors emanating from the LEDs is consistent and harmonious. It’s about creating a visual narrative pleasing to the eye, ensuring the hues are in sync, whether it’s the warm amber of a cozy cafe or the cool white of a modern office.

Luminous Flux Binning

Luminous Flux Binning is the maestro orchestrating the brightness of LEDs, ensuring each diode shines with a brilliance that is both consistent and mesmerizing. It’s not merely about illuminating a space; it’s about providing brightness as a narrative of quality and reliability.

Voltage Binning

Voltage Binning in the LED domain is akin to tuning the instruments before a grand orchestra. It’s about ensuring each LED operates within a specified voltage range, a narrative of safety and efficiency intertwined with luminous performance.

Temperature Binning

Temperature Binning is the narrative of understanding the temperament of LEDs, categorizing them based on the temperature range where they shine the brightest. It’s about ensuring the performance of LEDs is optimized, catering to the diverse environments they are destined to illuminate.

Step-by-Step: The Process of LED Binning

The narrative of LED binning unfolds meticulously, and each step is choreographed towards achieving the pinnacle of quality and consistency.

Step 1: Sorting LEDs by Voltage and Brightness

The prologue of LED binning is a careful audition, where LEDs are evaluated based on their voltage and brightness. This is the crucible where the raw material is assessed, and each LED’s performance is scrutinized to ensure it’s fit for the subsequent stages. It’s not merely about gauging the voltage and brightness; it’s about providing each LED is primed for the meticulous process, embodying the requisite parameters to graduate to the next phase.

Step 2: Slicing the Semiconductor into Die

As the narrative progresses, slicing the semiconductor into a die is a pivotal chapter. This precise operation lays the foundation for the LEDs, carving out individual dies that are now ready to be orchestrated into a luminous symphony. The precision here is not just about accurate slicing; it’s about setting the stage for the individual LEDs to shine, each die a protagonist in the narrative of LED binning.

Step 3: Wire Bonds and Electrical Connections

Establishing robust electrical connections is akin to scripting a dialogue between the LED and its power source. It’s about forging a bond that ensures the seamless flow of electricity, orchestrating an uninterrupted and flawless performance. The wire bonds are the conduits, providing the narrative of light unfolds seamlessly, and each LED eloquently articulates its luminous history.

Step 4: LED Binning

The heart of the narrative is the act of LED binning, a meticulous process where LEDs are categorized based on various parameters. It’s about orchestrating a harmonious collective in its color and brightness, and each LED is a harmonious note in this luminous ensemble. The binning is not just a process; the meticulous choreography ensures the collective luminous output is a spectacle of consistency and quality.

Step 5: LED Quality Control

The curtain call in the LED binning saga is rigorous quality control. This finale ensures each LED is primed to dazzle in the market. It’s the last checkpoint, the final review that provides each LED embodies the pinnacle of quality, ready to enchant the audience with its luminous brilliance.

Unraveling the Difference: Color Binning vs Flux Binning

The narrative of Color and Flux Binning is a tale of two distinct yet intertwined domains. While Color Binning orchestrates the hue, Flux Binning choreographs the glow, each a unique dance ensuring the LED product blends aesthetic allure and functional excellence.

Factors on the Table: Considerations While LED Binning

The saga of LED binning is a nuanced choreography, with myriad factors orchestrating the rhythm.

Bin Criteria

The criteria for binning is akin to the script of a play, guiding the process and ensuring each LED is categorized with a non-negotiable precision. It’s about crafting a narrative where each LED is placed in its rightful category, ready to play its part in the grand spectacle of light.

Technological Considerations

In the grand theater of LED binning, technology is the director ensuring each act is executed with a finesse that mirrors the sophistication of a Broadway production. The technology employed is the backbone, orchestrating a process that is accurate, efficient, and exemplary in achieving the desired quality and consistency.

Adhering to Industry Standards for LED Binning

Industry standards are the benchmarks, the gold standards that ensure the narrative of LED binning is one of professionalism and excellence. Adherence to these standards is non-negotiable, ensuring the process of LED binning is conducted with unparalleled rigor and quality.

Navigating Environmental Regulations for LED Binning

In the narrative of LED binning, adhering to environmental regulations is a chapter that underscores the ethos of responsibility and sustainability. It’s about ensuring the process is not just about achieving luminous excellence but doing so in an ecologically responsible and sustainable manner.

Feeling the Heat: Thermal Effects of LED Binning

Temperature is not just a measure of heat; it’s a variable that significantly influences the LED binning process. It’s akin to a capricious dancer whose movement, though beautiful, can alter the rhythm of the LED binning ensemble. Understanding the thermal effects, mitigating the potential thermal discrepancies, and ensuring that the LEDs can perform optimally across a spectrum of temperature conditions are quintessential to the success of LED binning.

Navigating the Hurdles: Common Issues with LED Binning

Venturing into the domain of LED binning is akin to navigating a maze with its fair share of challenges. These hurdles, ranging from maintaining color consistency to ensuring the robustness of electrical connections, are the crucibles that test the efficacy of the LED binning process. Identifying these challenges, devising strategies to navigate them, and ensuring smooth sailing through the binning process reflects the innovation and resilience inherent in this domain.

Probing the Light: How to Test a Binned LED?

Evaluating a binned LED is not merely a technical process but a meticulous rehearsal ensuring that it is primed for its role in the grand luminous theatre. It’s about testing its color, brightness, and voltage, ensuring the LED is ready to dazzle with its consistent and reliable performance. Each test is a step towards ensuring that the LED is prepared to perform and enchant with its luminous brilliance.

Tips for Refining Your LED Binning Process

The quest for refining the LED binning process is a pursuit of luminous excellence. It’s about honing the technique, enhancing the technology employed, and ensuring that the ensemble of LEDs curated is nothing short of spectacular. It’s about embracing the innovations, learning from the challenges, and continually striving to elevate the LED binning process to higher precision and consistency.

Burning Questions: FAQs

What exactly are LED Bin Codes?

LED Bin Codes are identifiers assigned to groups of LEDs during the binning process. These codes provide information regarding the specific characteristics of the LEDs, such as color, brightness, and sometimes voltage. Through these bin codes, manufacturers and consumers can easily discern the quality and specifications of the LEDs, ensuring they match the requirements of the intended application. They act like a passport, offering a glimpse into the intrinsic properties of the LEDs, thus simplifying the selection and quality assurance process.

Are there established industry standards for LED binning?

Yes, there are industry standards for LED binning, which are set to ensure consistency, quality, and reliability in LED products. These standards dictate the acceptable tolerances in color, brightness, and other parameters, ensuring that the LEDs meet the expectations and requirements of various applications. Adhering to these standards also helps maintain uniformity and interchangeability among LED products from different manufacturers.

Is it possible to conduct LED binning in the manufacturing phase?

LED binning is an integral part of the manufacturing process. It is conducted after the initial production of LEDs but before they are assembled into finished products. While it’s part of the broader manufacturing phase, it’s a distinct step that ensures the categorization of LEDs based on their characteristics. This segregation aids in maintaining quality control and ensuring that the final LED products meet the desired specifications.

How does binning contribute to the color consistency of LED lights?

Binning is instrumental in ensuring color consistency among LED lights. LEDs are grouped based on their color output during the binning process, among other parameters. This process ensures that all LEDs within a particular bin exhibit similar color characteristics, guaranteeing a uniform color output when utilized in lighting products. It eradicates the chances of color discrepancies, pivotal for applications where color uniformity is a crucial requirement.

Is the LED binning process necessary for all LED light variants?

The necessity of LED binning largely depends on the application and the quality standards required. LED binning is indispensable for high-quality lighting solutions, especially where color consistency and brightness are crucial. However, LED binning might be less important for less critical applications or products where minor variances in color or brightness are acceptable. It’s the desired quality and the application requirements that dictate the necessity of LED binning.

What are the typical binning tolerances observed in LED lights?

Binning tolerances refer to the allowable variations in the characteristics of LEDs within a bin. Common tolerances include variations in color, brightness, and voltage. The exact tolerances can vary based on the manufacturer’s standards and the application’s specific requirements. However, narrower tolerances are often synonymous with higher quality as they ensure a greater consistency in the LED’s performance.

Are there any potential downsides to the LED binning process?

While LED binning is crucial for ensuring quality and consistency, it can also contribute to the overall cost and time required to manufacture LED products. The process necessitates additional equipment, labor, and time to accurately sort and bin the LEDs. However, the benefits of improved quality, consistency, and meeting the application requirements often outweigh the associated downsides.

How does binning influence the dimming capabilities of LED lights?

The binning process can influence the dimming capabilities of LED lights. LEDs binned for similar voltage and brightness levels will likely exhibit consistent dimming performance. On the other hand, LEDs with significant variances in these parameters may exhibit inconsistent dimming behavior. Therefore, the binning process is pivotal in ensuring that LEDs within a product or system provide consistent dimming performance, contributing to the overall quality and user experience.

What’s the relevance of the CIE 1931 Diagram in LED Binning?

The CIE 1931 Diagram plays a quintessential role in LED binning by serving as a scientific framework for color representation. Within the LED industry, color consistency is pivotal to quality, and the CIE 1931 color space provides a standardized method to define and measure color. The x and y coordinates on the CIE diagram represent chromaticity, which is the quality of color regardless of brightness. When it comes to LED binning, understanding the color coordinates of LEDs is essential to ensure they meet the desired color consistency and quality standards. The CIE 1931 Diagram acts as a roadmap guiding the binning process towards achieving a harmonious color output among a group of LEDs, ensuring that the color perception remains uniform across different LED products. By adhering to the standards set forth by the CIE 1931 Diagram, manufacturers can effectively bin LEDs to meet specific color requirements, making it an indispensable tool in the LED binning process.

How does Temperature Binning factor into the LED Binning process?

Temperature Binning is a nuanced yet significant aspect of the LED binning process. Every LED has a particular temperature range within which it operates optimally. Temperature binning involves categorizing LEDs based on their temperature characteristics, ensuring they perform efficiently across varied environmental conditions. This process is vital as it helps mitigate the thermal effects that can impact the performance and longevity of LEDs. By understanding and categorizing LEDs based on their temperature attributes, manufacturers can ensure that the LEDs are suited for their intended applications, whether they are to be used in hot, cold, or temperate conditions. Temperature binning, thus, adds another layer of precision to the LED binning process, ensuring that the LEDs not only shine bright but also remain resilient and efficient in varying temperature conditions. Through temperature binning, manufacturers can provide more accurate specifications and guarantees regarding how LEDs perform under different temperature scenarios. This makes it an invaluable aspect of the LED binning process.

Conclusie

The odyssey through the realm of LED binning illuminates the meticulous choreography and precision that culminates in the creation of an LED product. It’s an enlightening journey that beckons curious minds to delve deeper, revel in the symphony of light around us, and appreciate the luminous melody that brightens our world. LED binning is not just a technical domain; it’s a brilliant saga that plays a pivotal role in orchestrating the spectacle of light we often take for granted.

Diving into the meticulous process of LED binning unravels the essence of quality and consistency that forms the bedrock of the LED industry. As you illuminate your understanding, let Unitopeen van China's toonaangevende LED-strip verlichting en LED neon flex manufacturers, further brighten your perspective. With a legacy of expertise, we invite inquiries and are here to cater to your LED needs. Bereiken to Unitop, and let’s illuminate a brighter tomorrow together.

Tom is nu de Sales Manager van Unitop (China) Co.. Hij is in de LED Verlichting industrie sinds 2005. Hij is een expert in verkoop & marketing, en fabrieksmanagement. Hij houdt van bodybuilding, en hij is ook een gekke Apple-fan! Hij is een hardwerkende man en houdt ervan te leren en nieuwe dingen te proberen.

Email: tom@unitopledstrip.com WhatsApp: +86-18680307140

Laat een reactie achter

Wil je meedoen aan de discussie?Voel je vrij om bij te dragen!