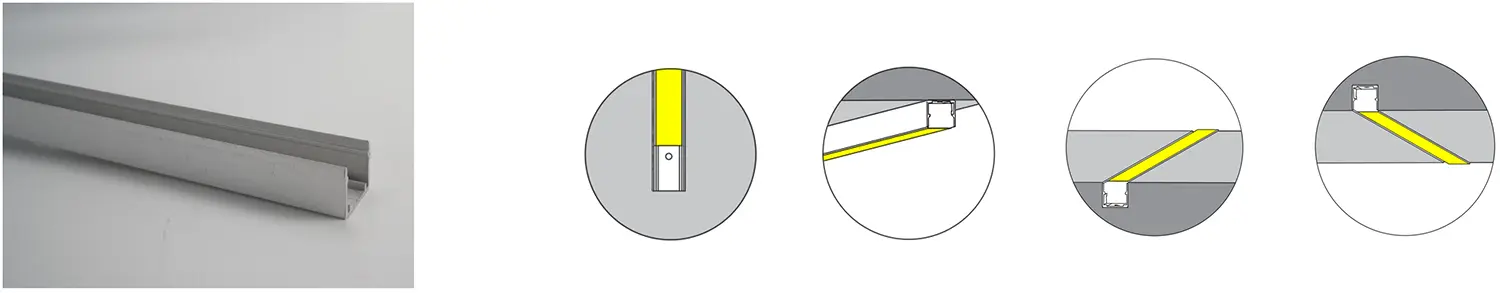

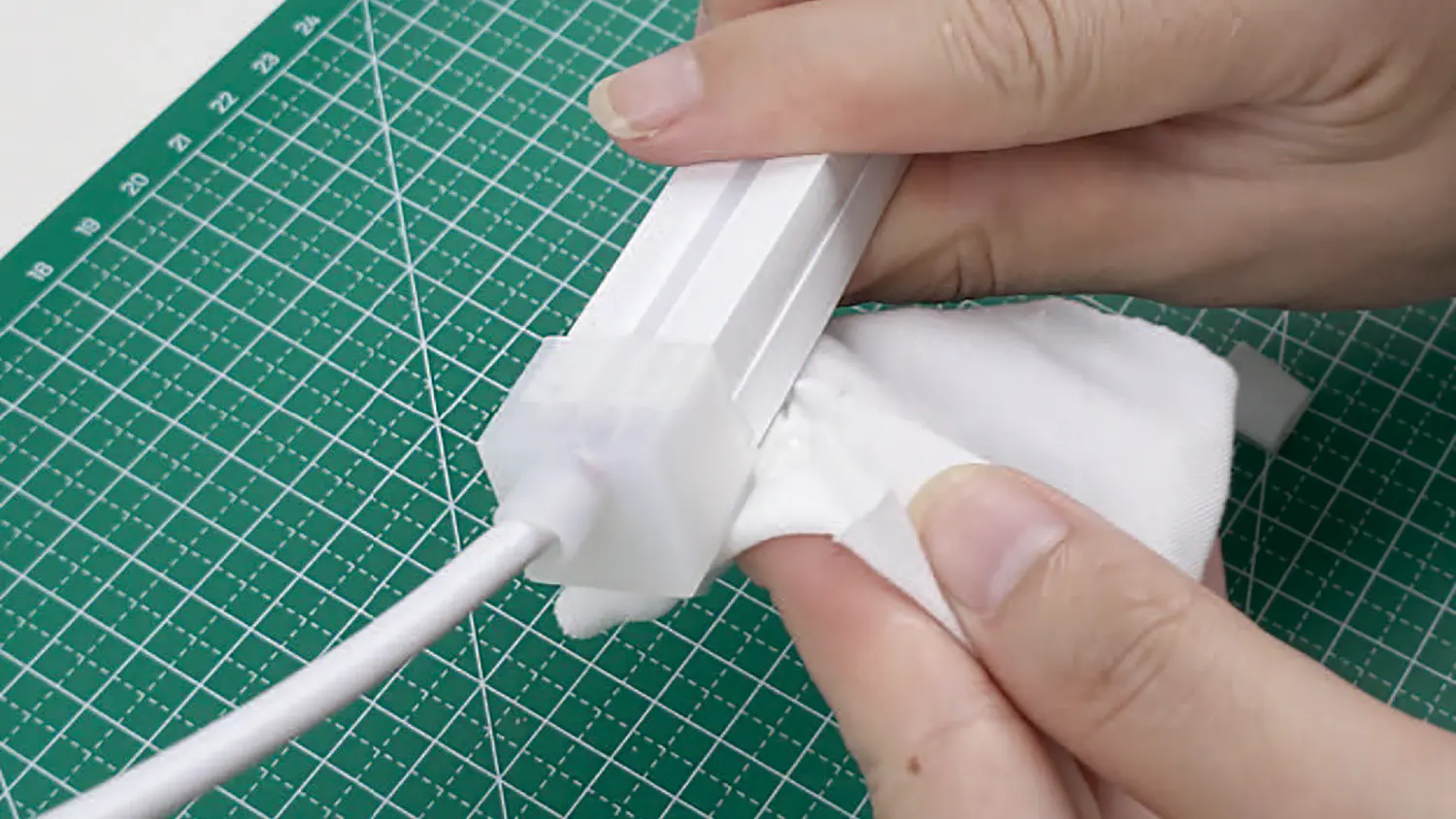

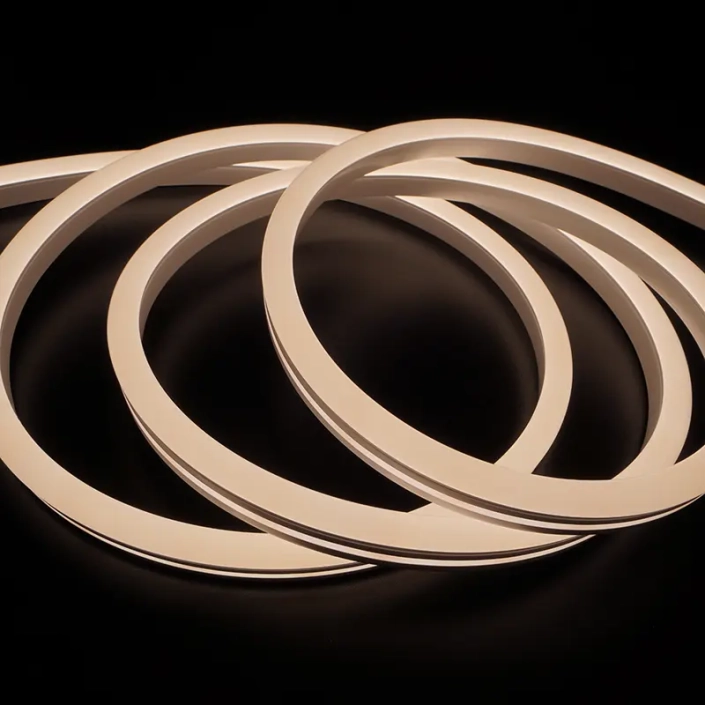

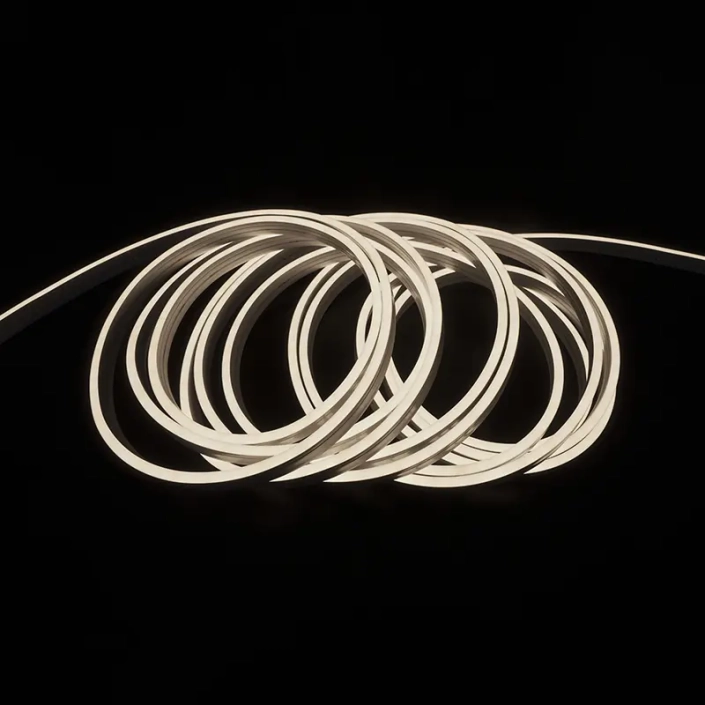

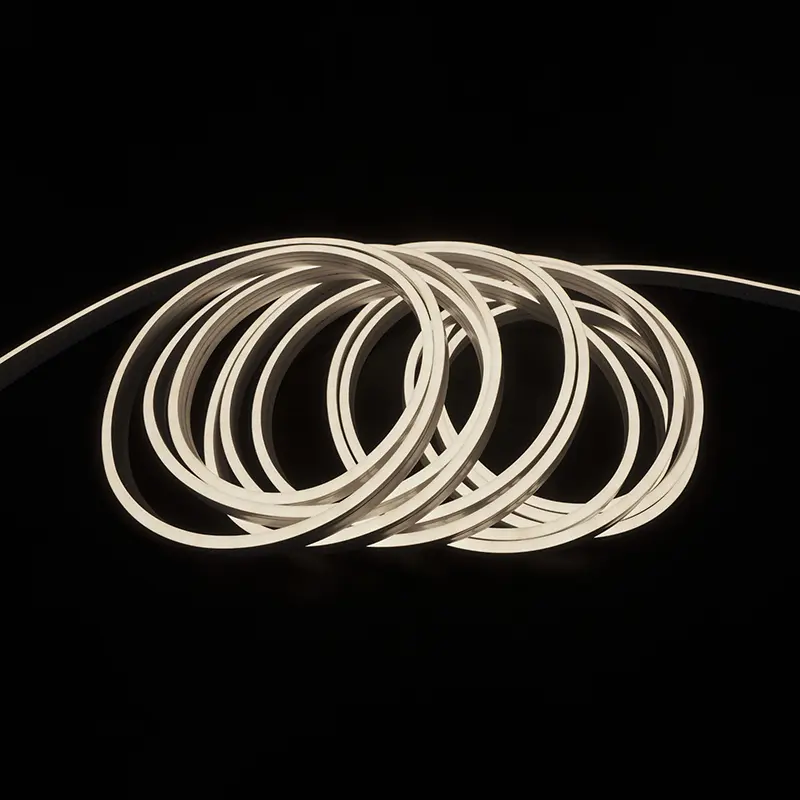

Side Bend LED Neon Flex Lighting 0812 IP67 24VDC 10W/M

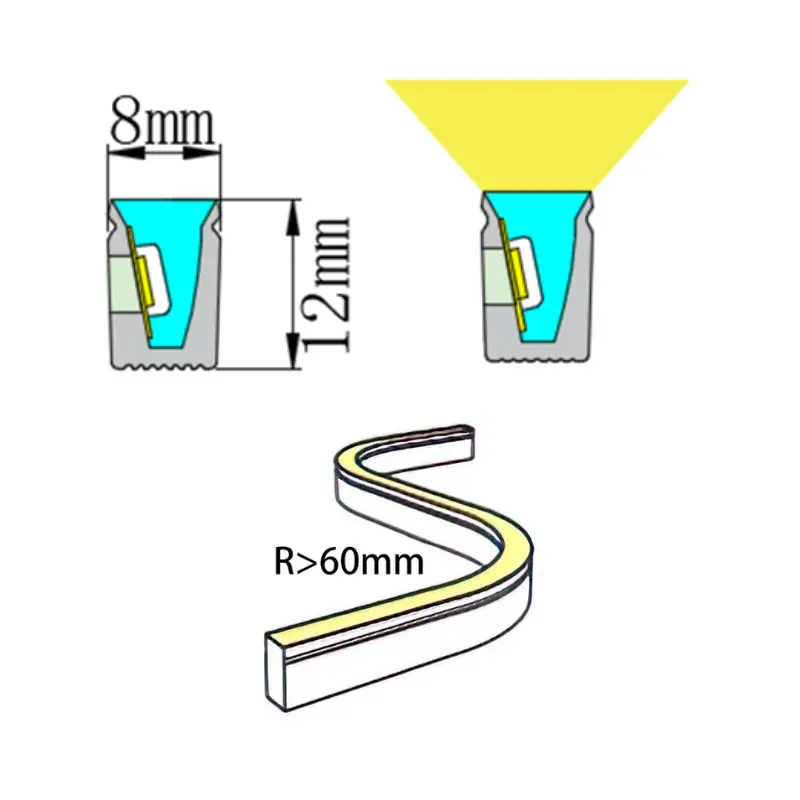

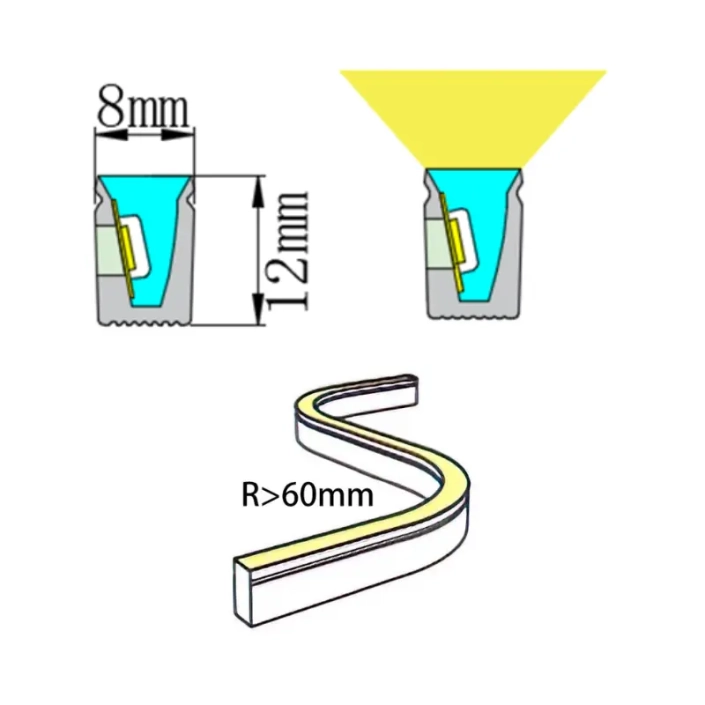

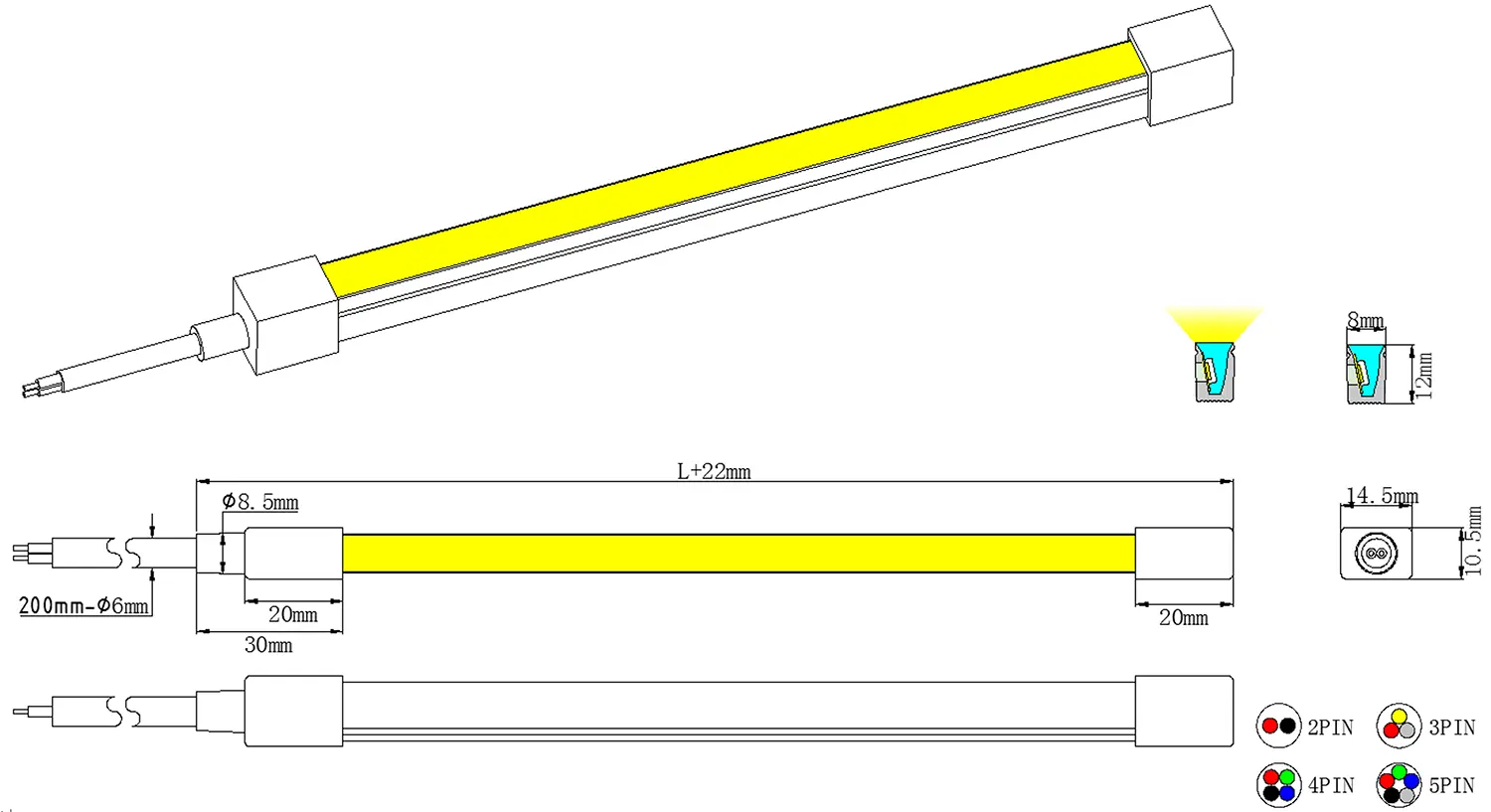

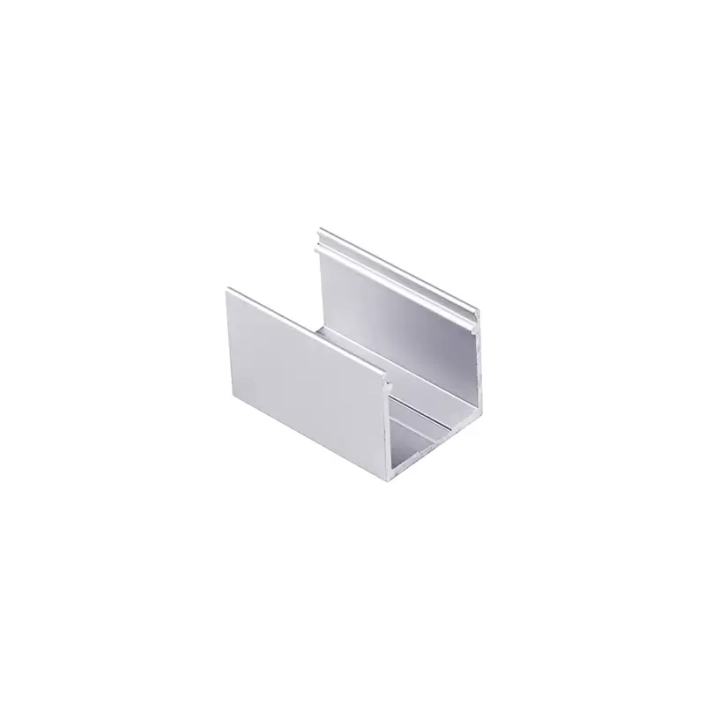

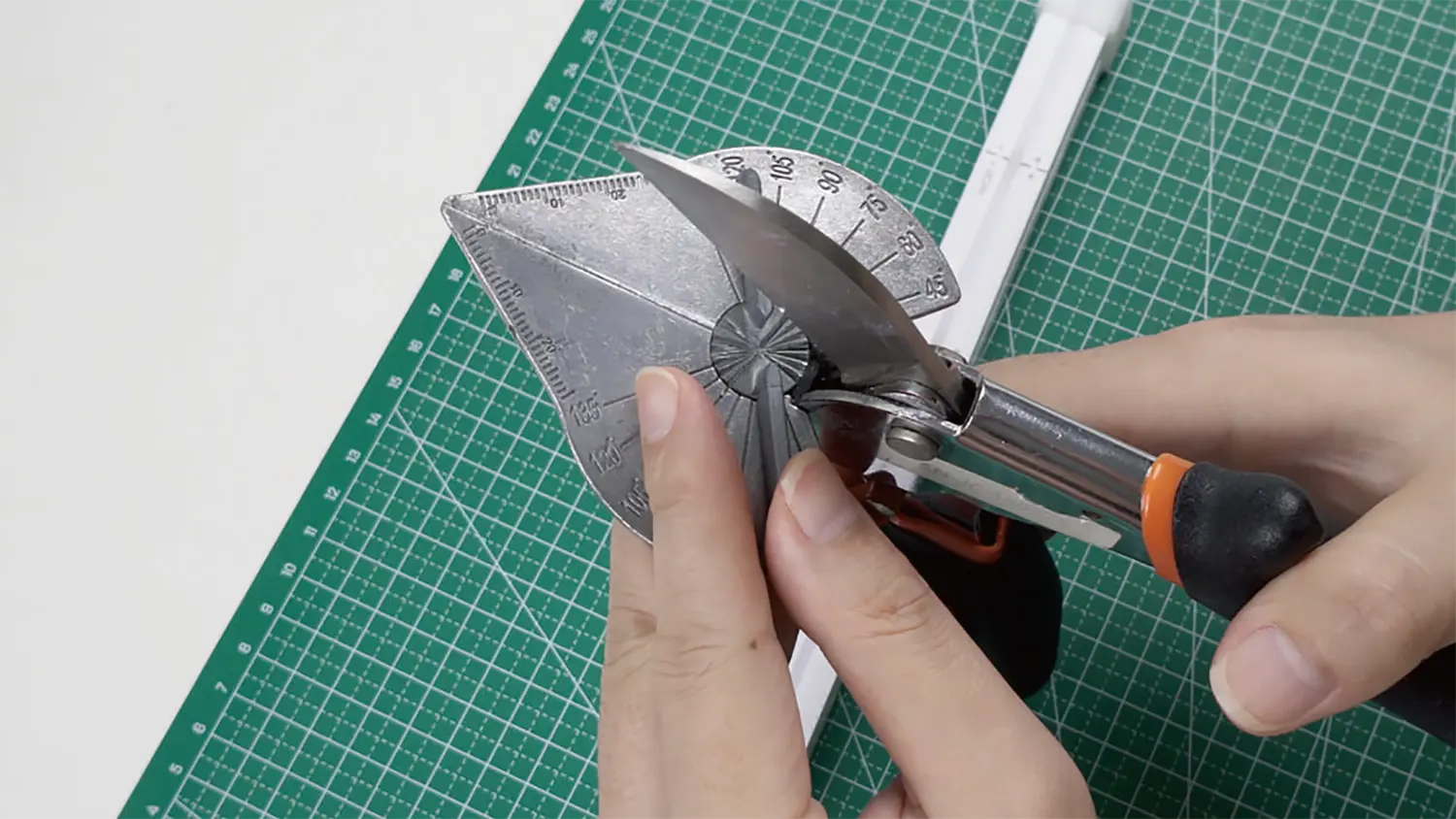

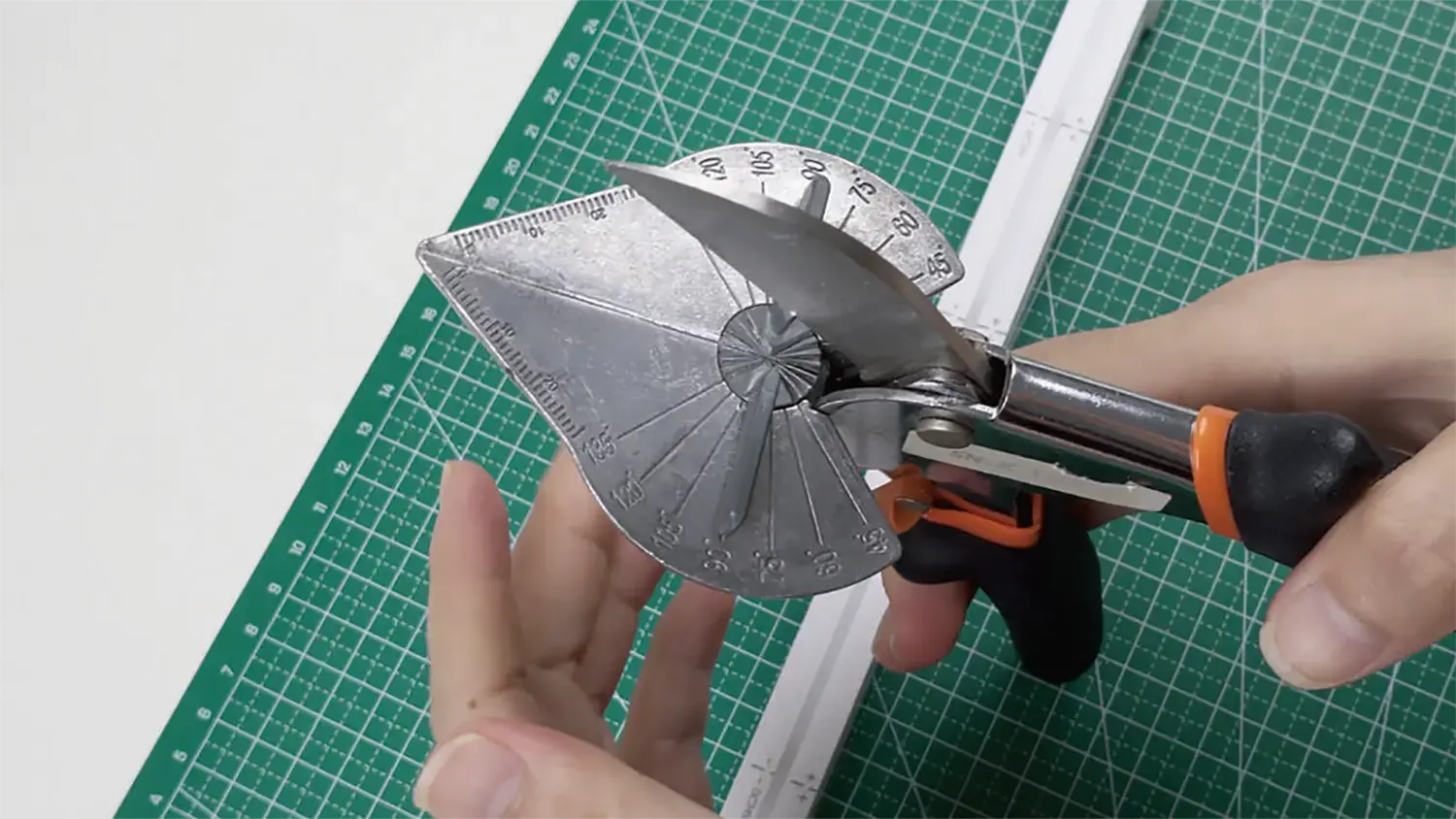

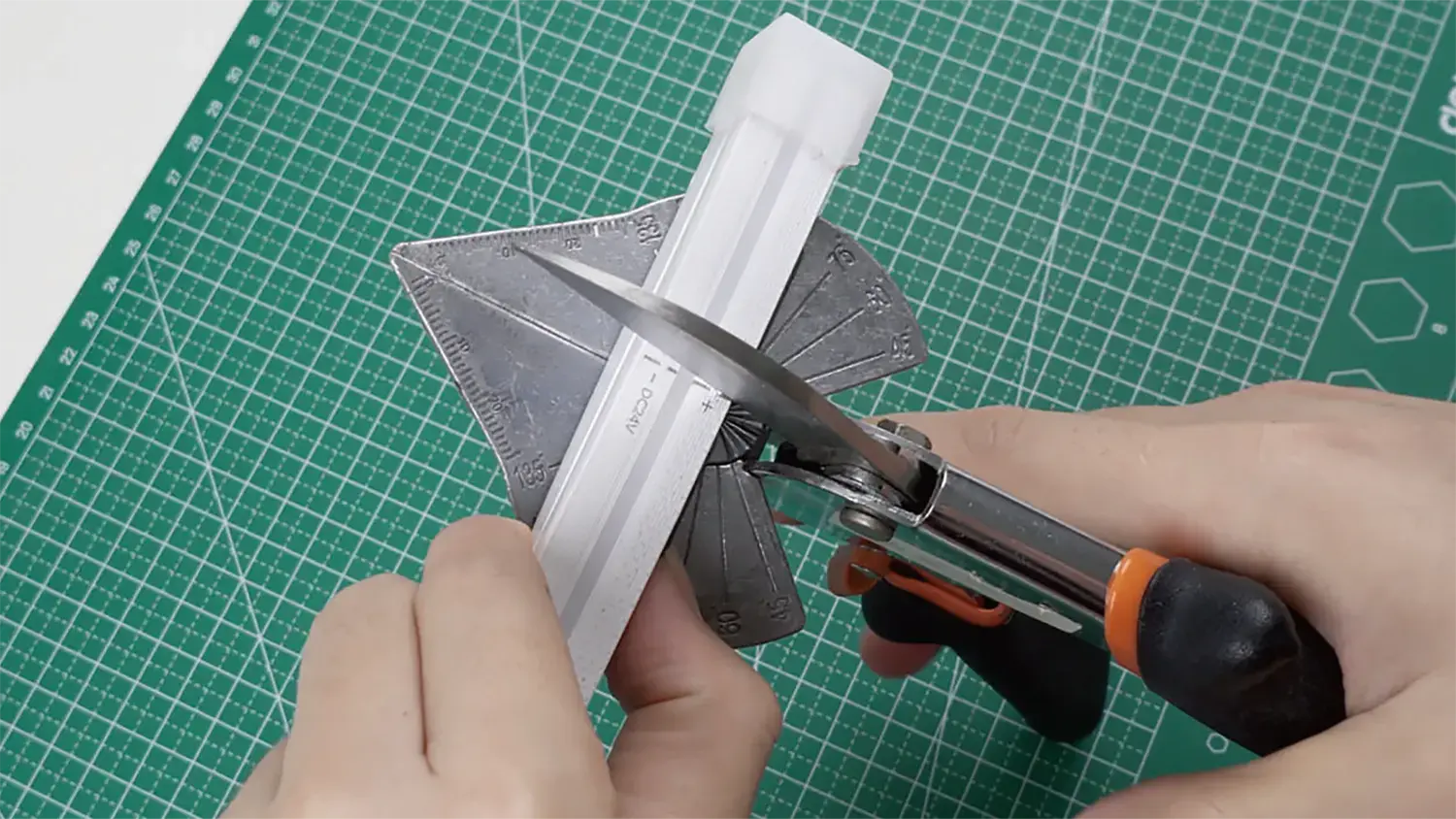

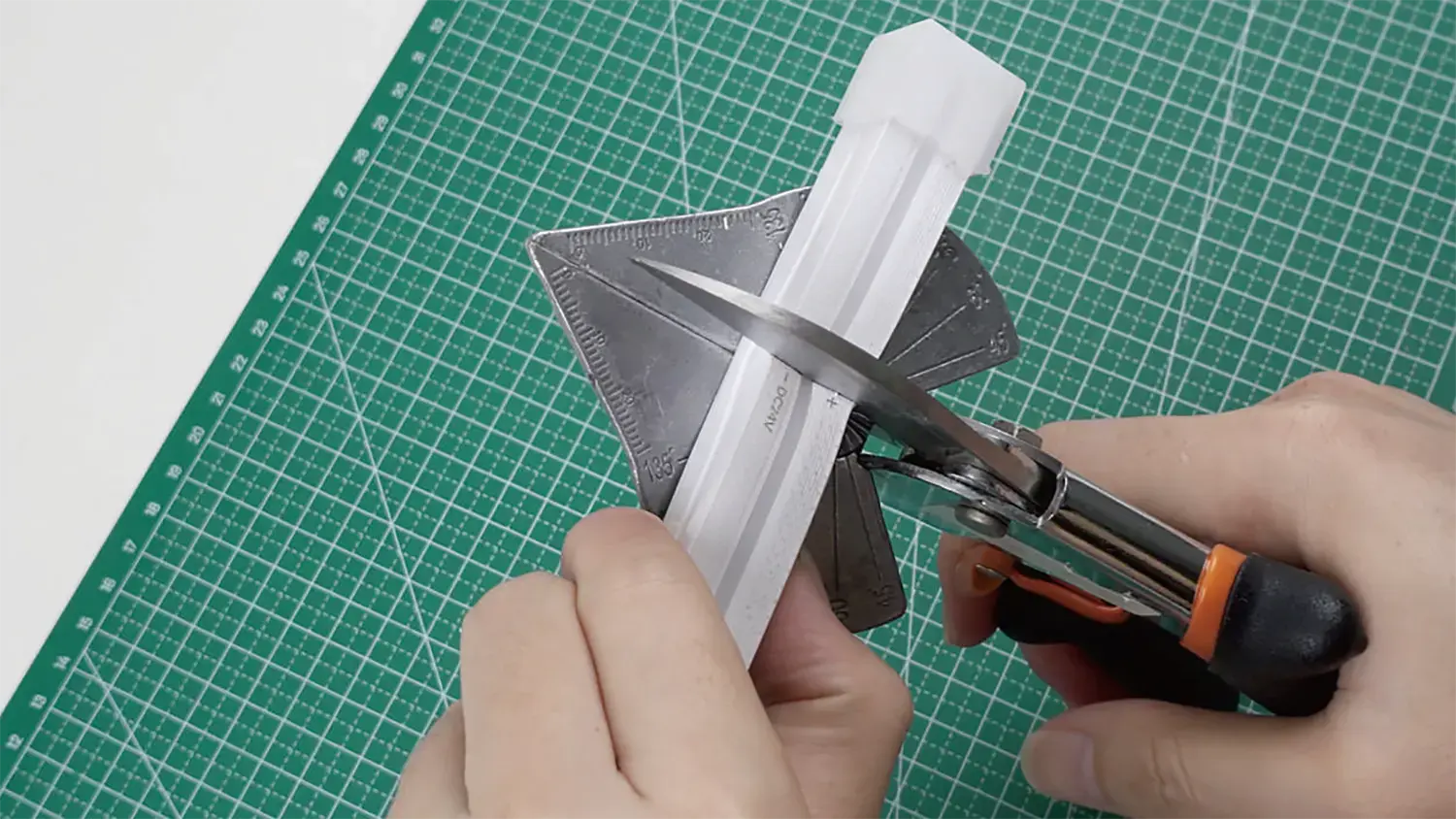

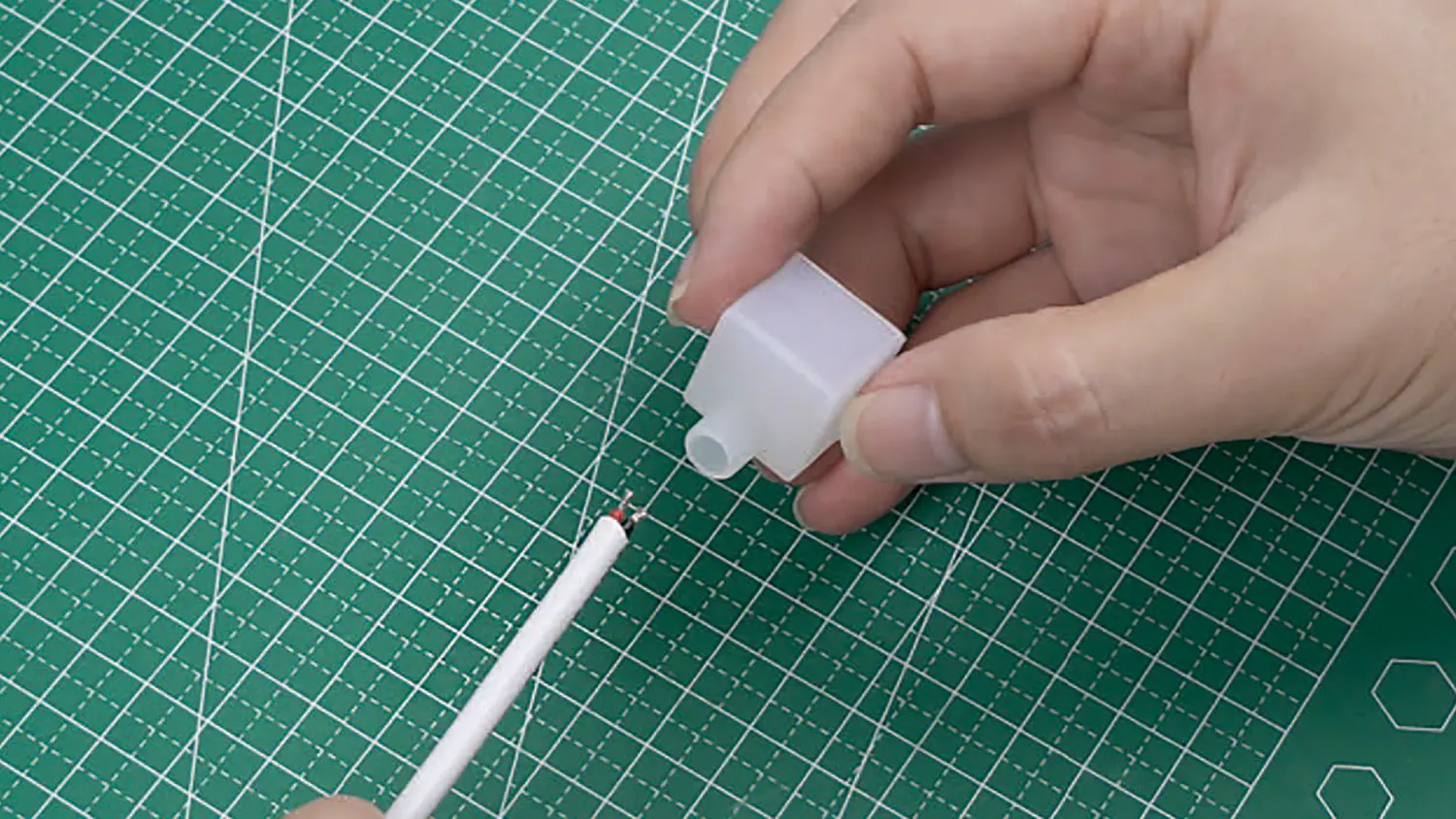

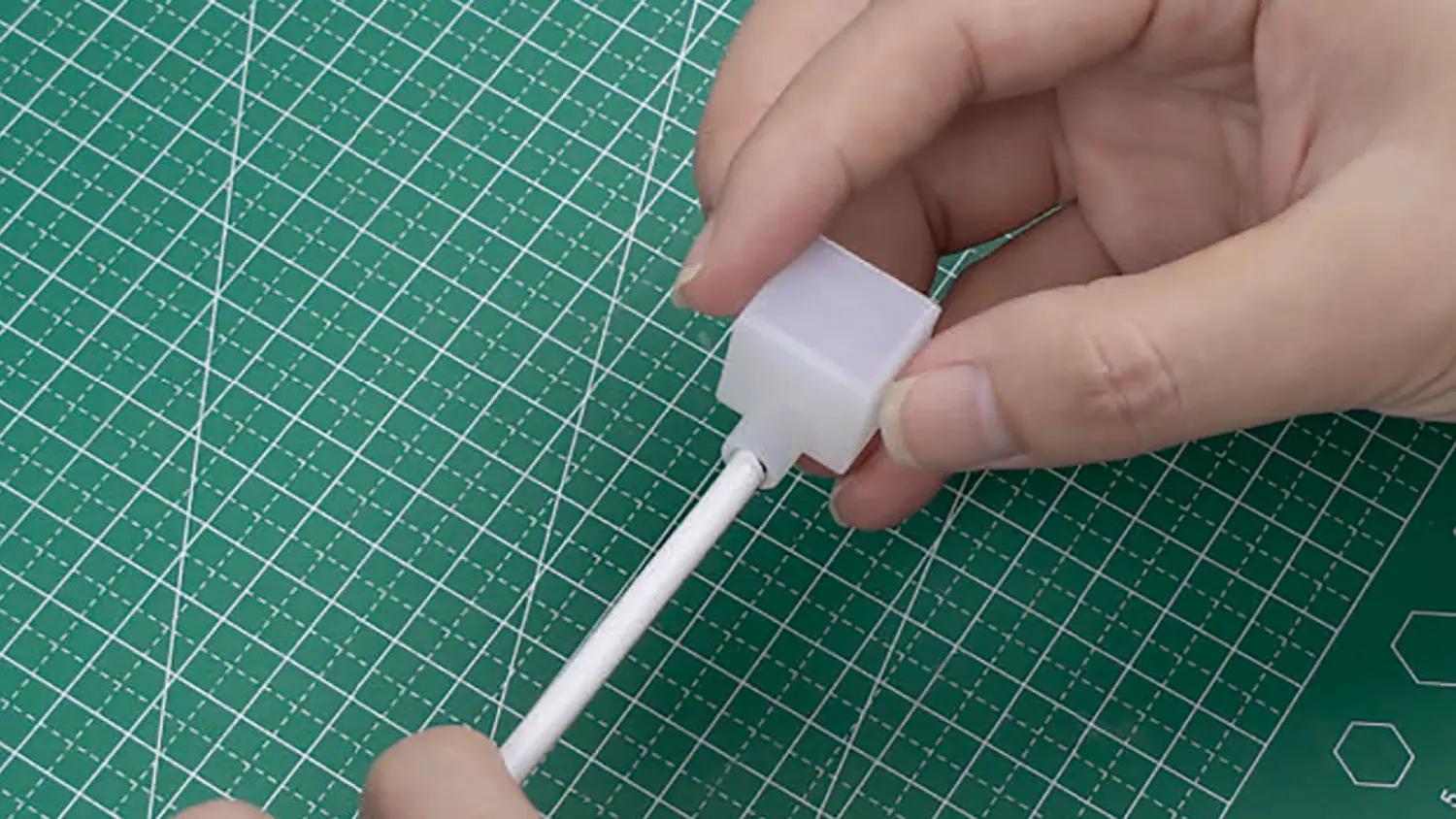

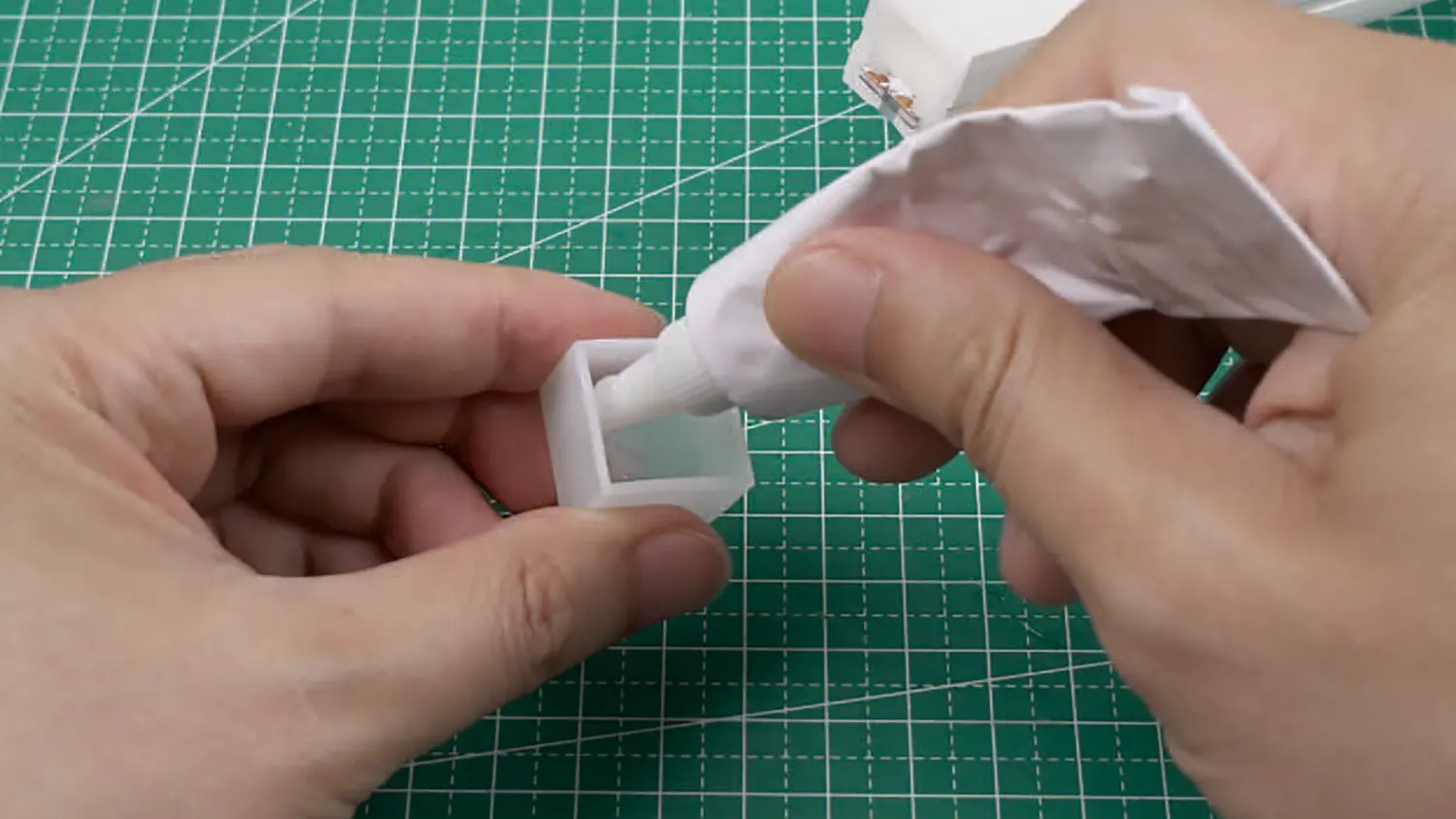

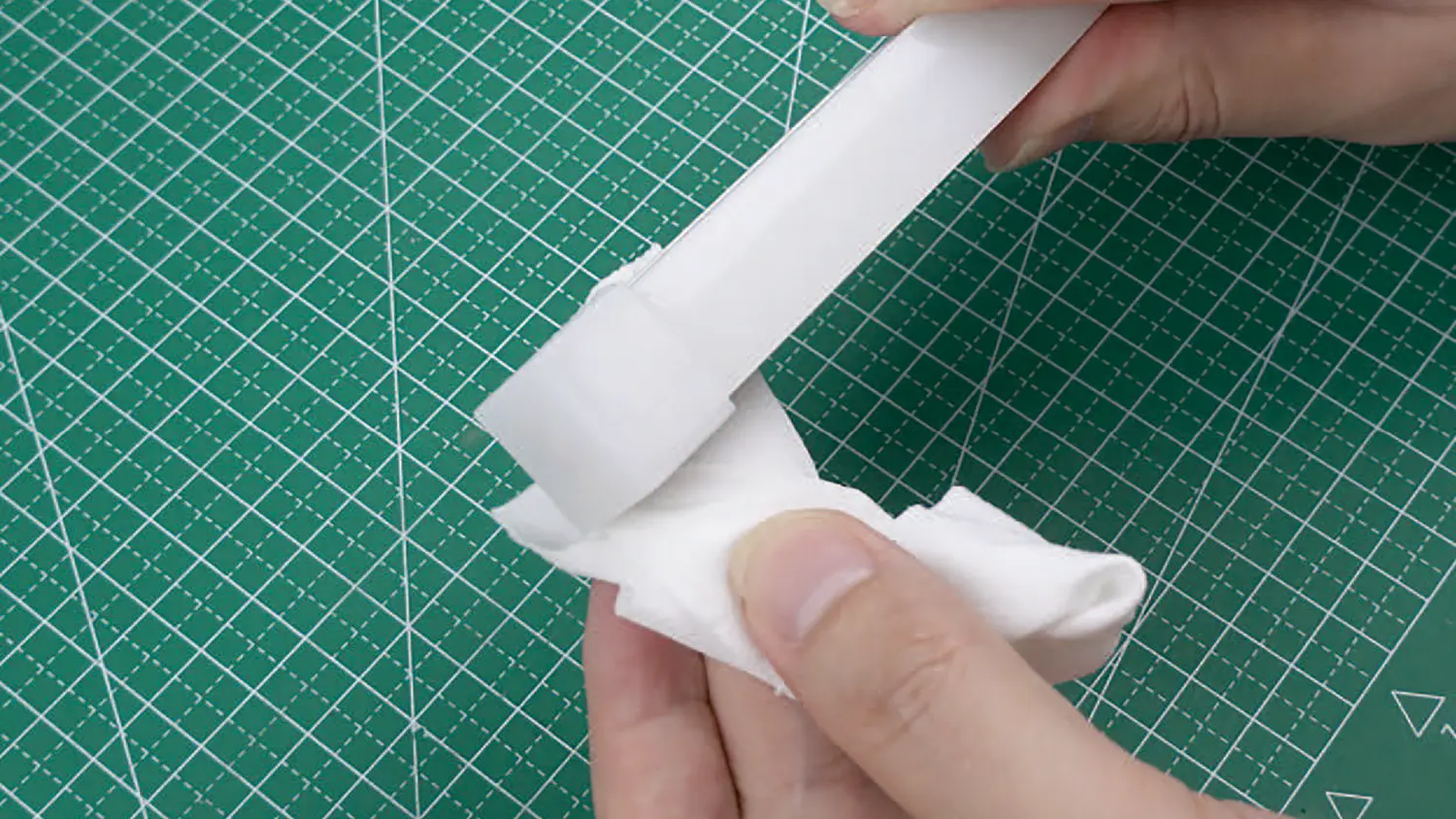

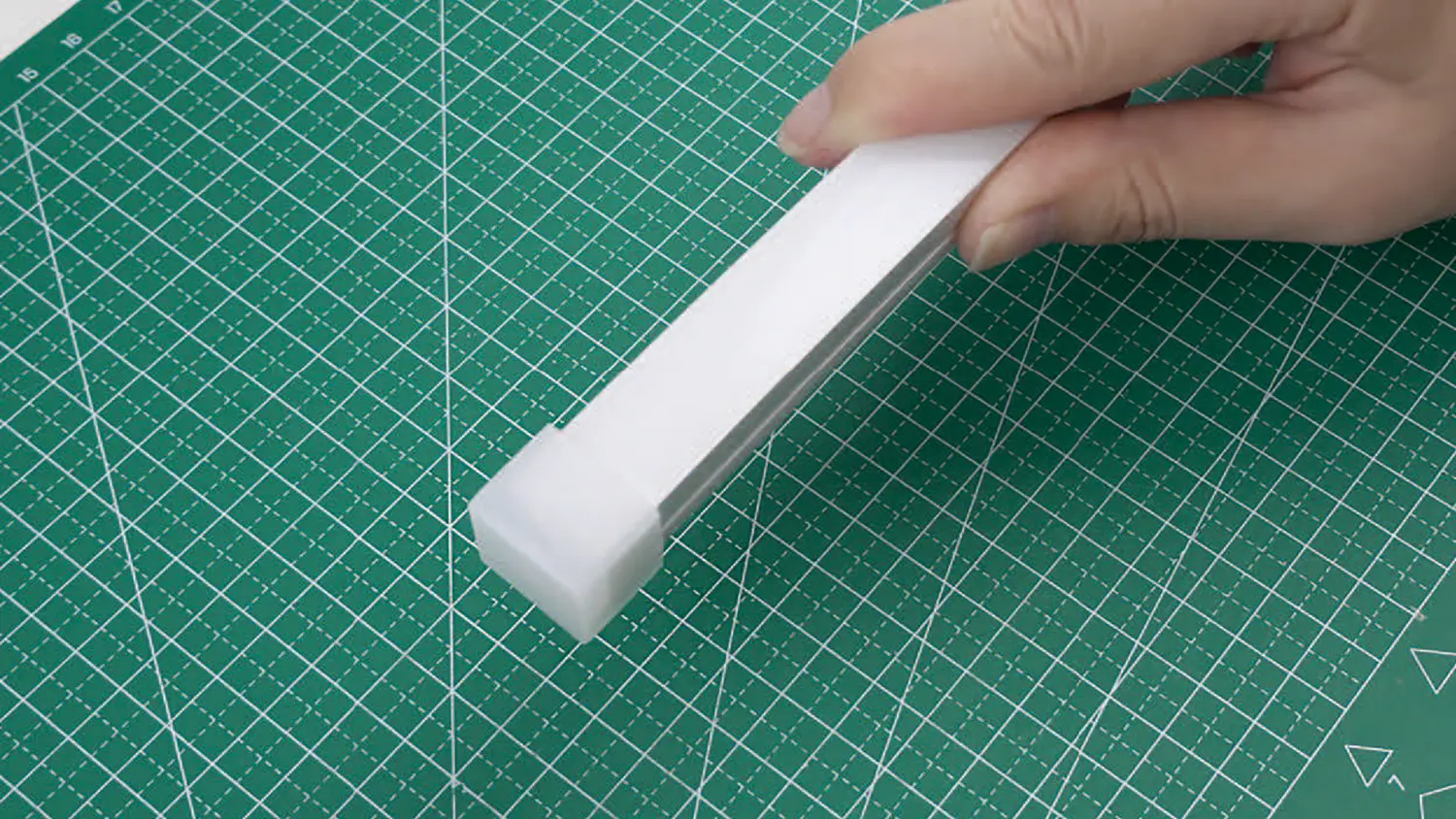

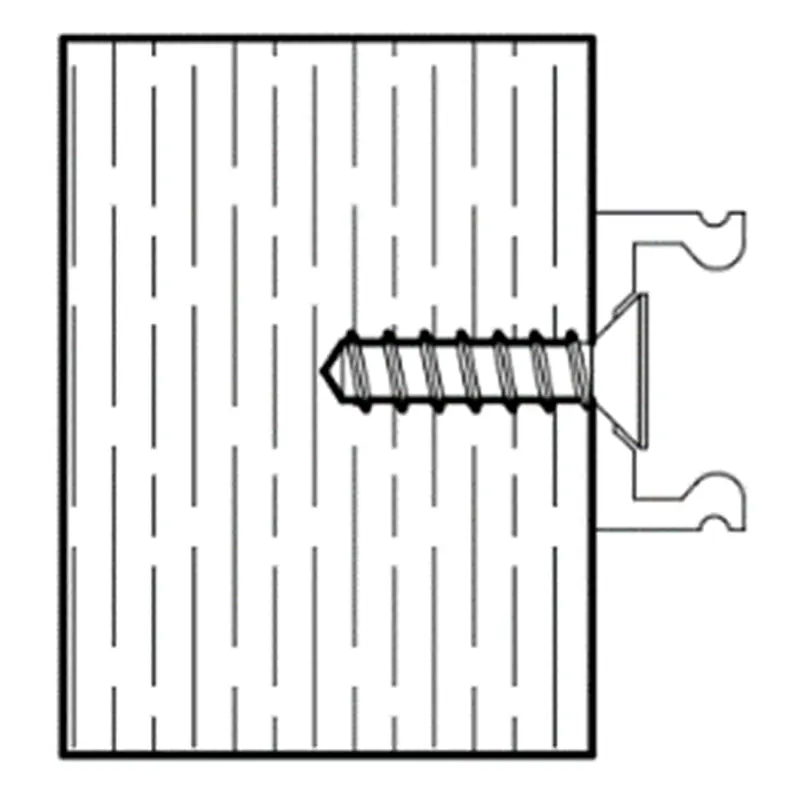

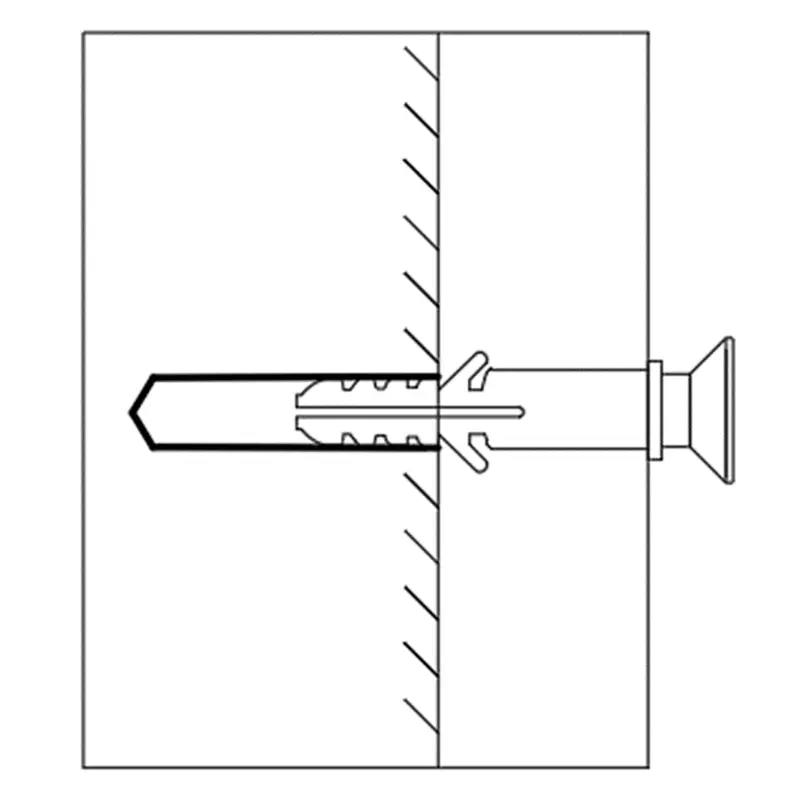

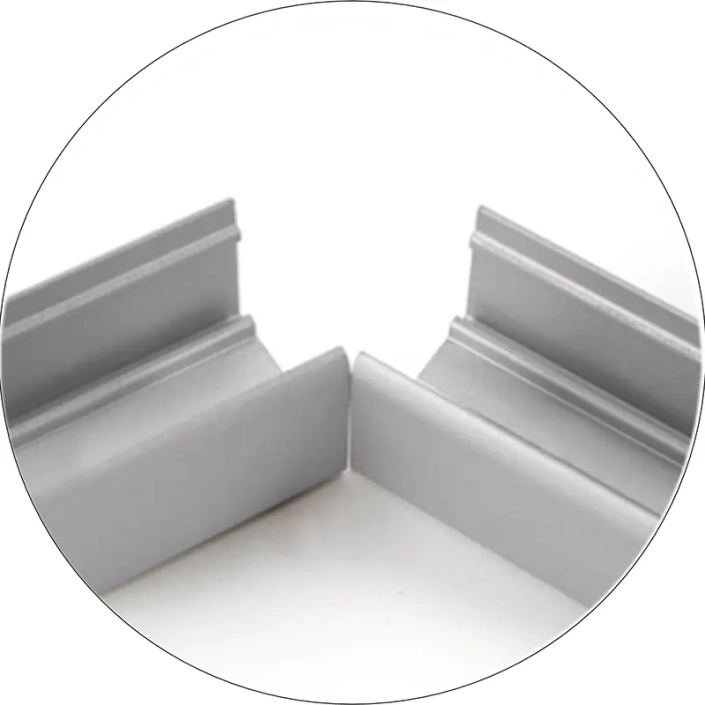

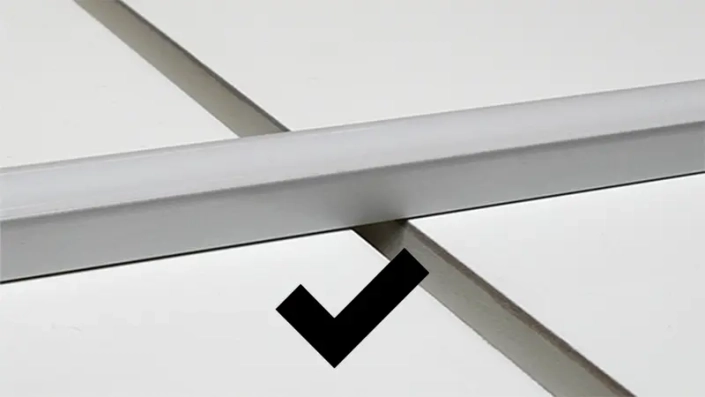

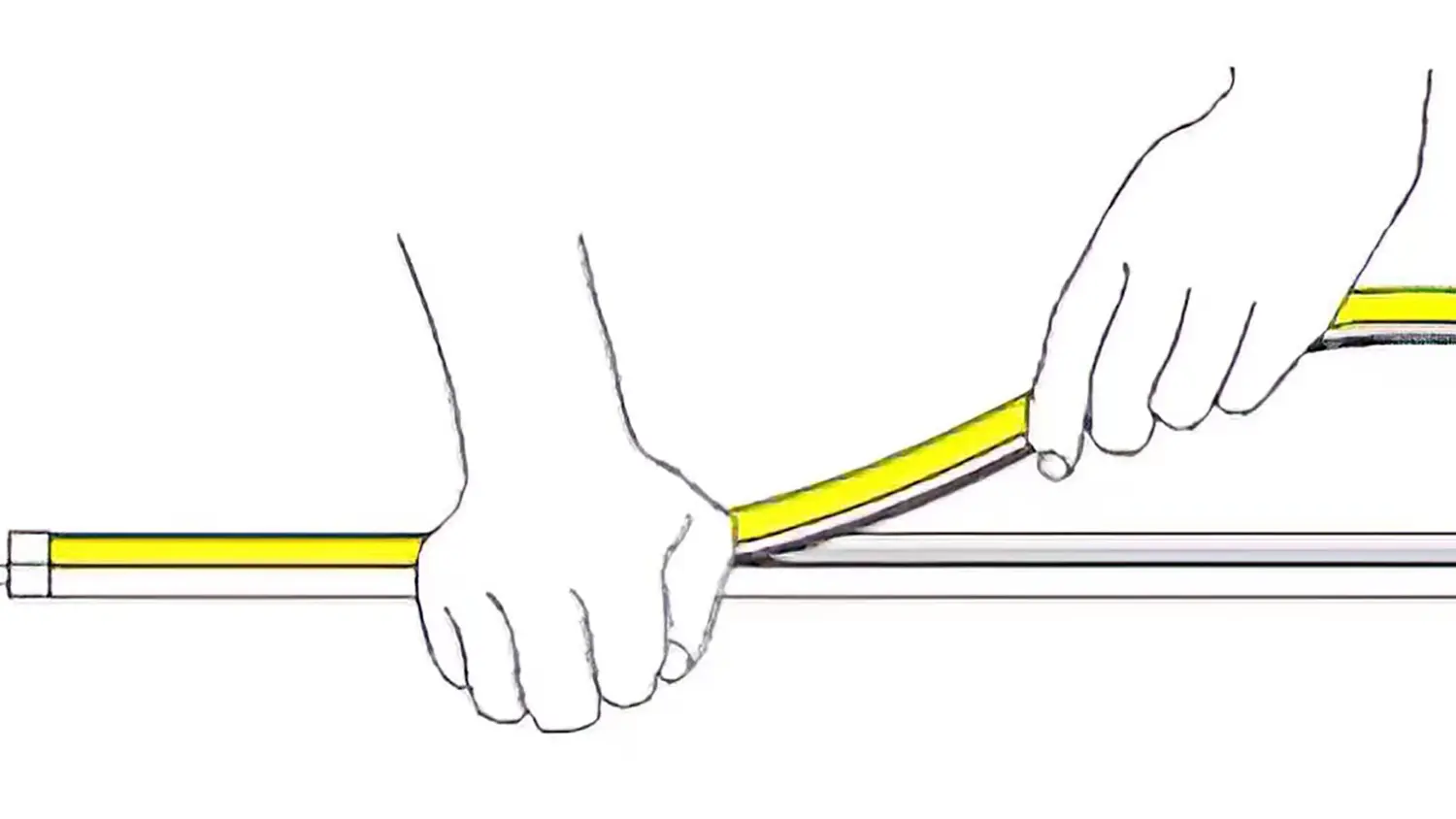

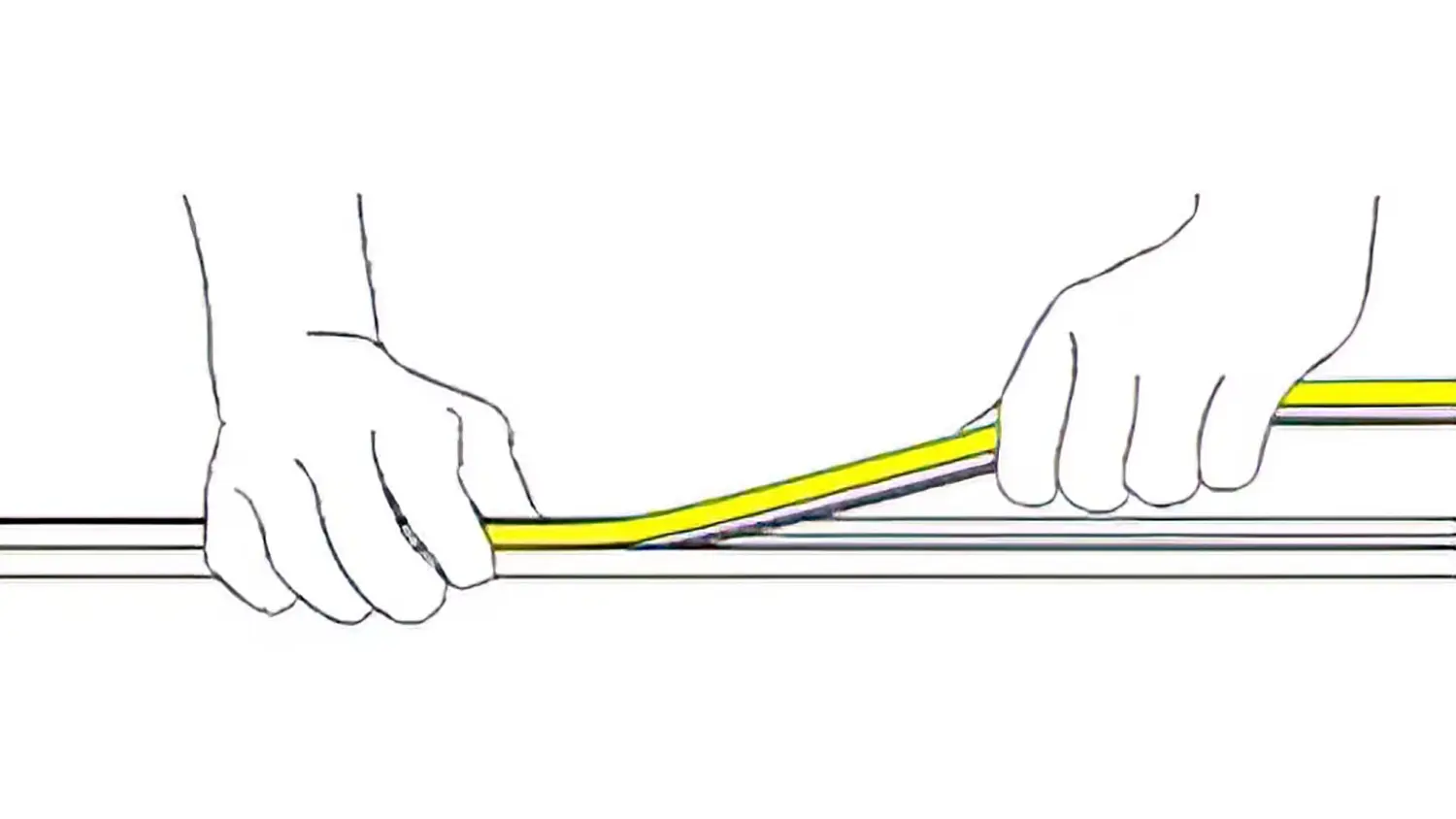

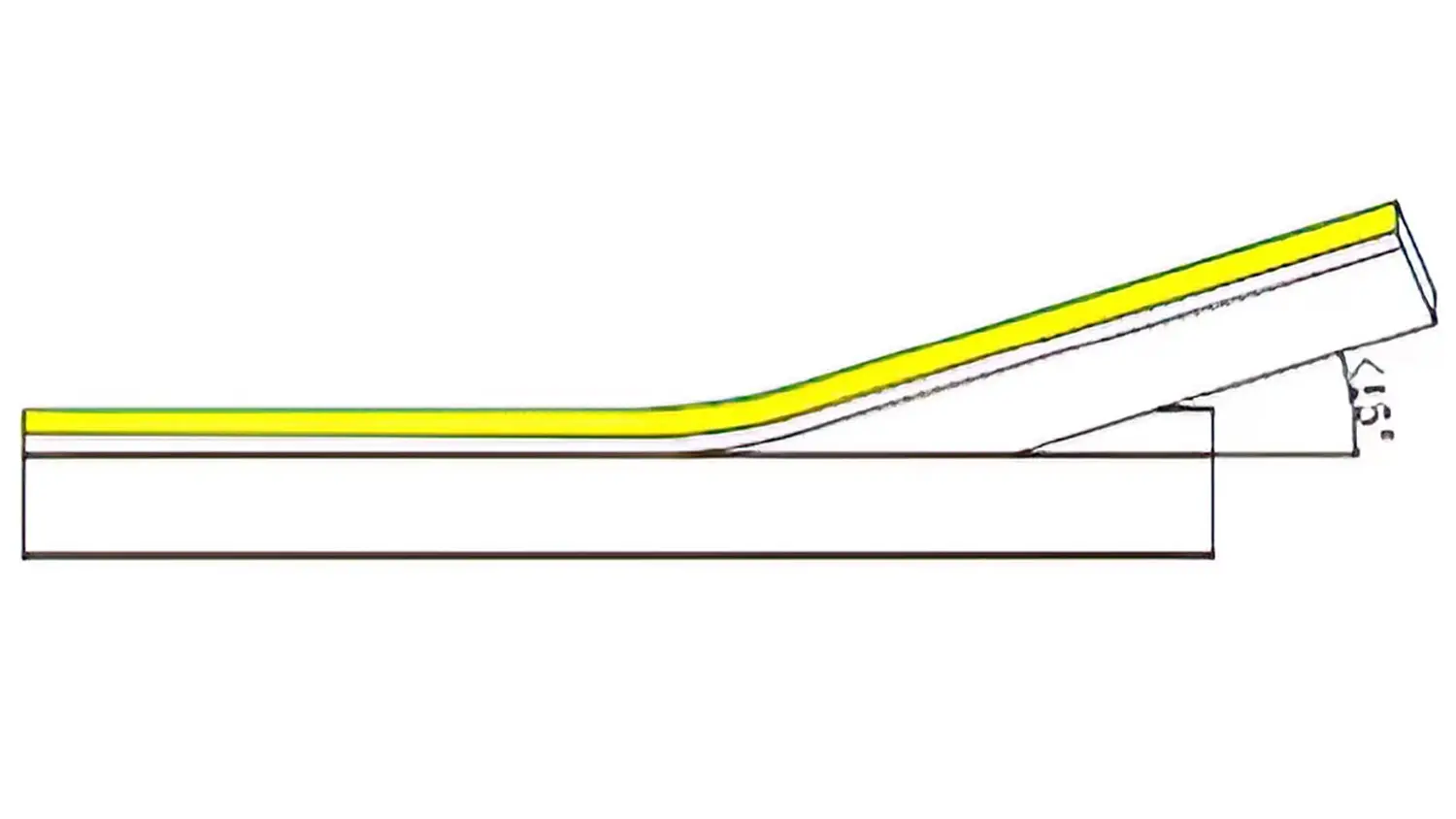

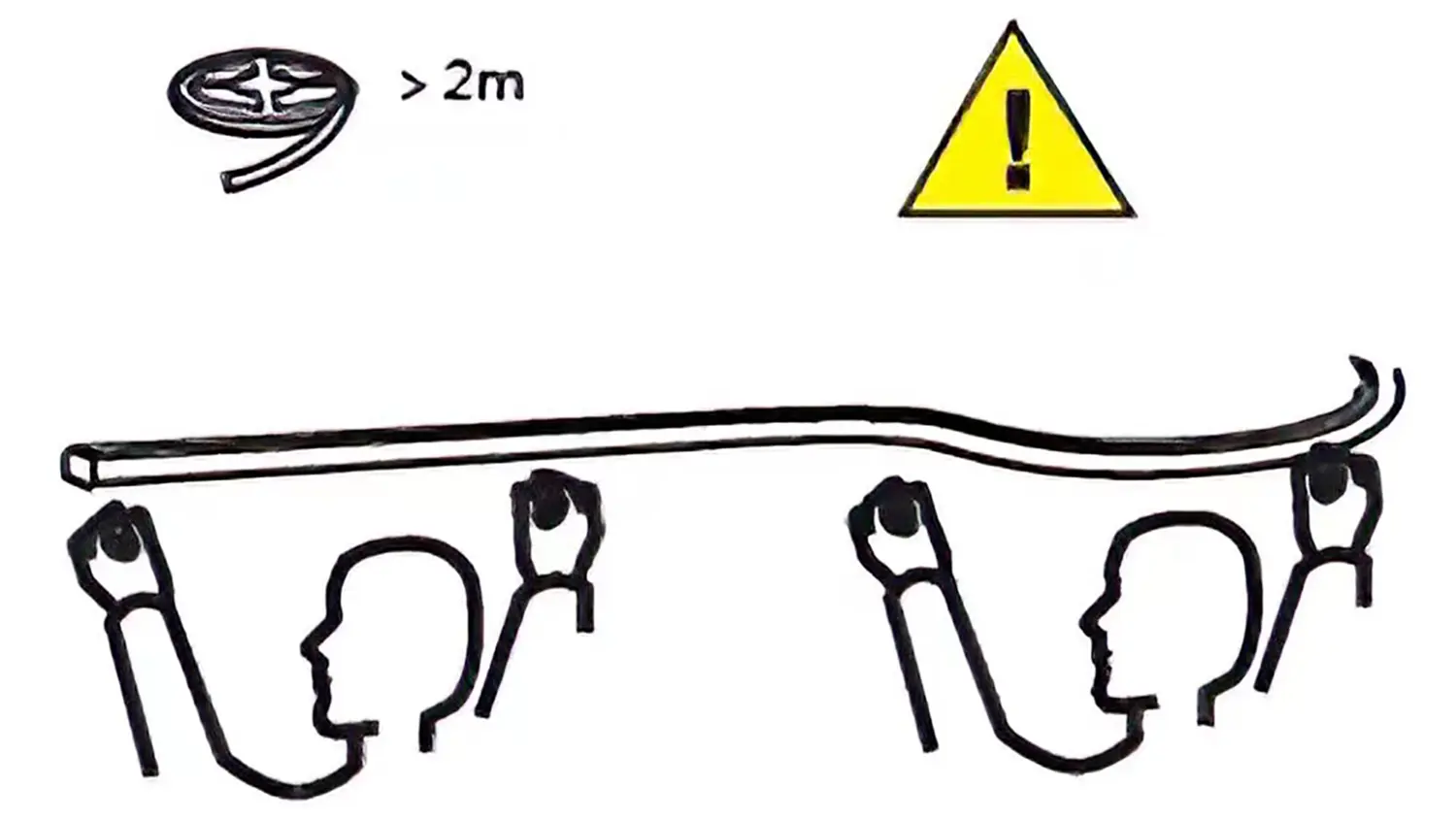

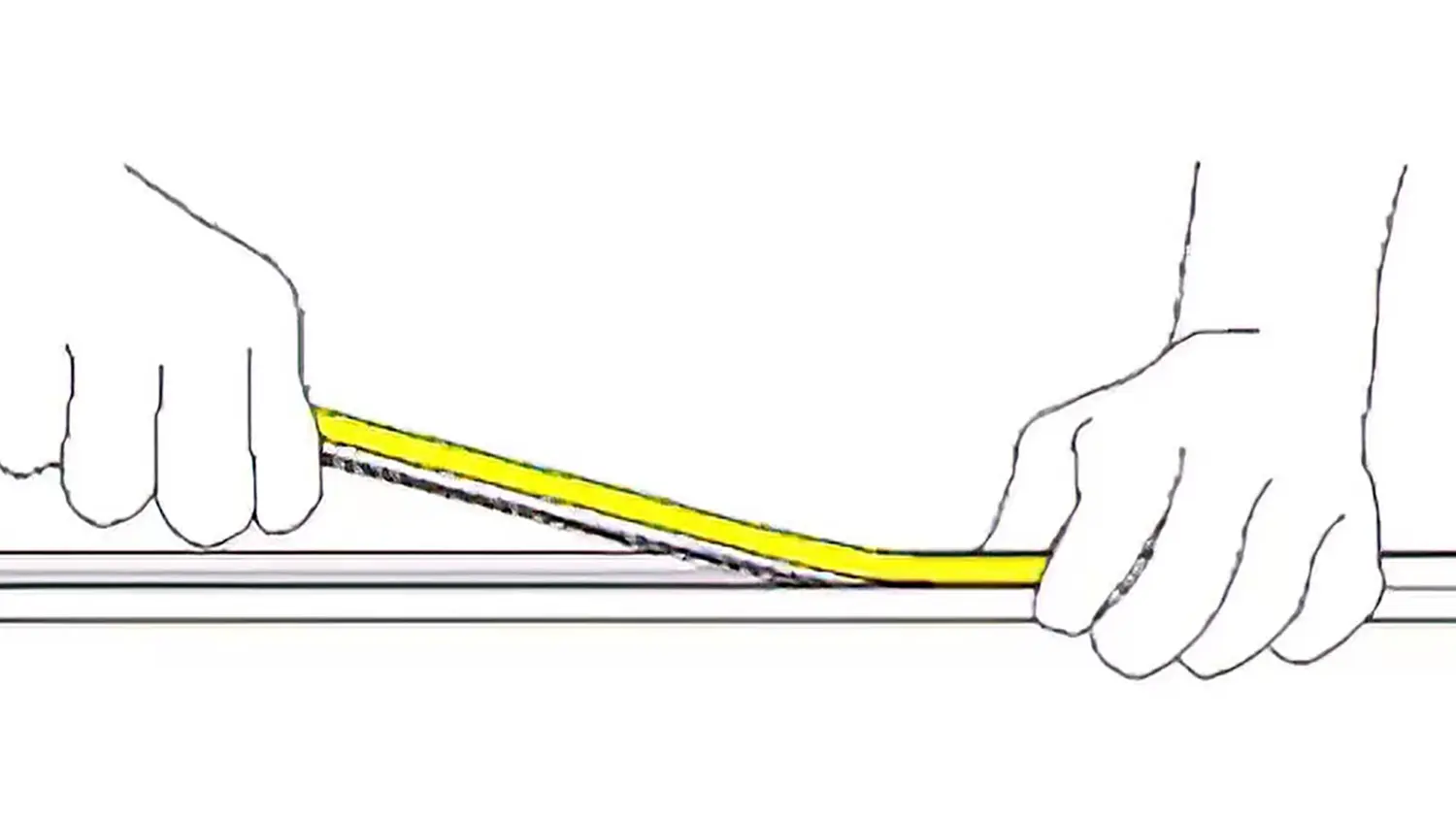

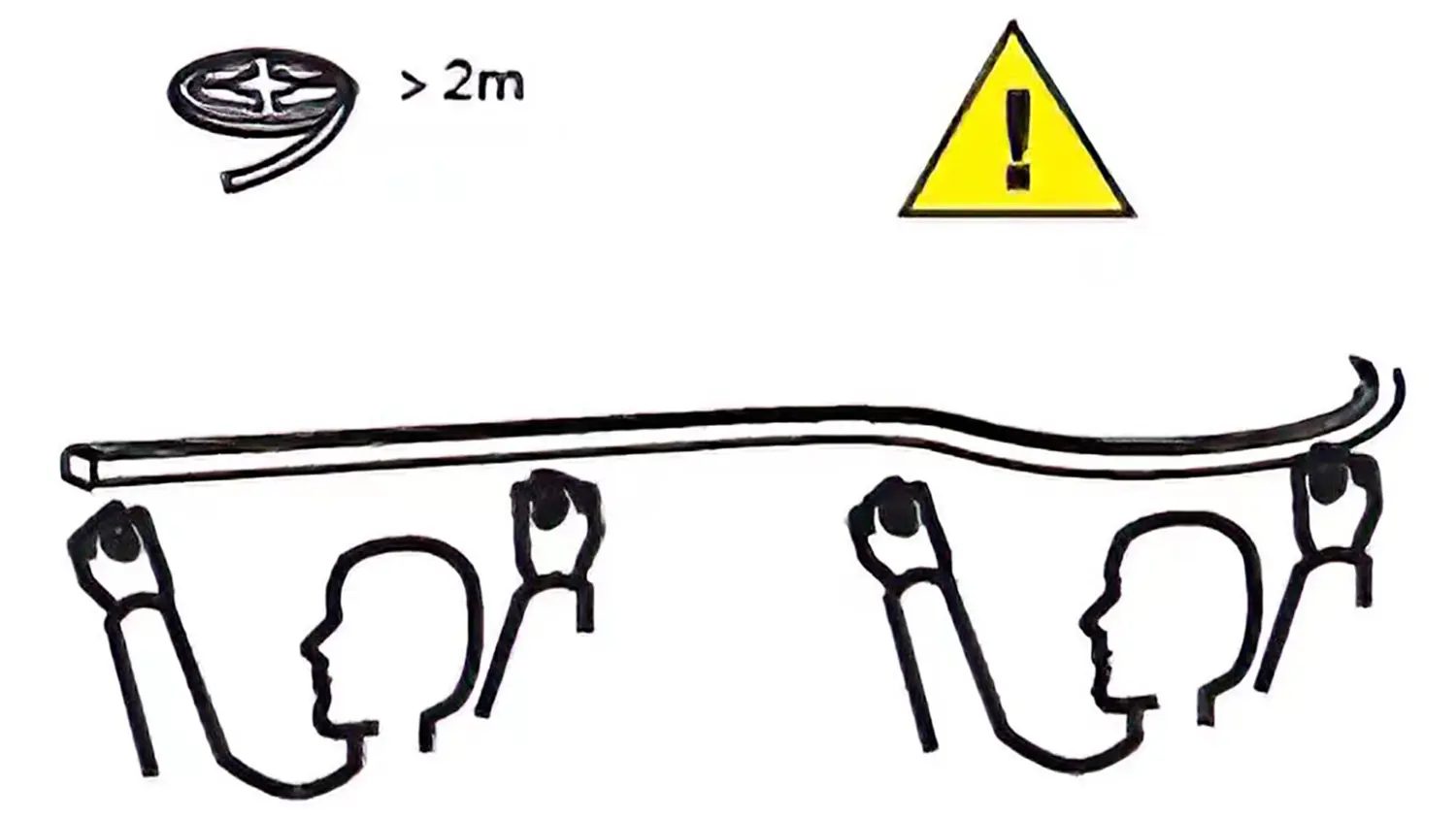

This Side Bend LED Neon Flex Rope Light is with side-bending design, 8mm light-emitting surface, 12mm height, SMD2835 LED as light source, and uniform light. With excellent horizontal bending flexibility, it is super bright and easy installation. Moreover, it is IP67 suitable for both indoor & outdoor decorative lighting and outdoor building outline lighting, etc.

| Nr modelu: | UTNF-SB0812 |

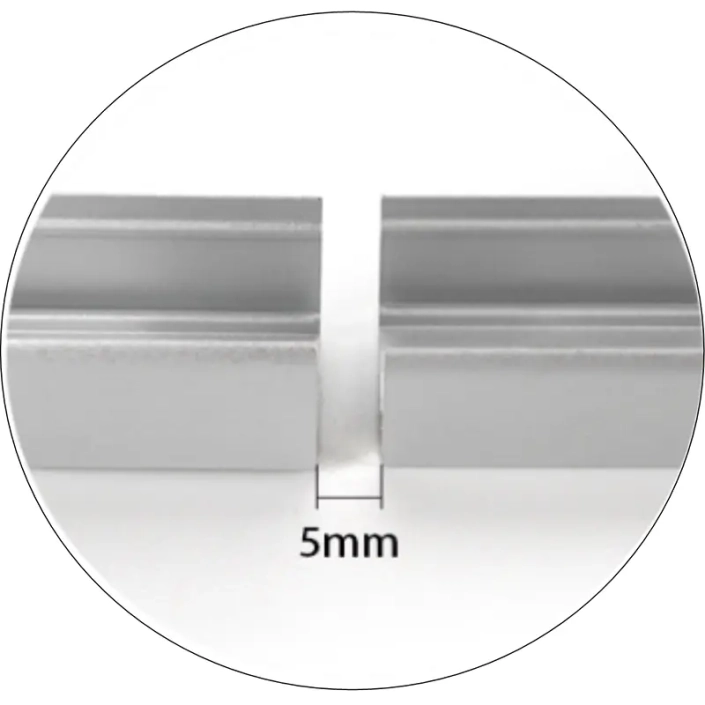

| Wymiar: | 8mm(W)x12mm(H) |

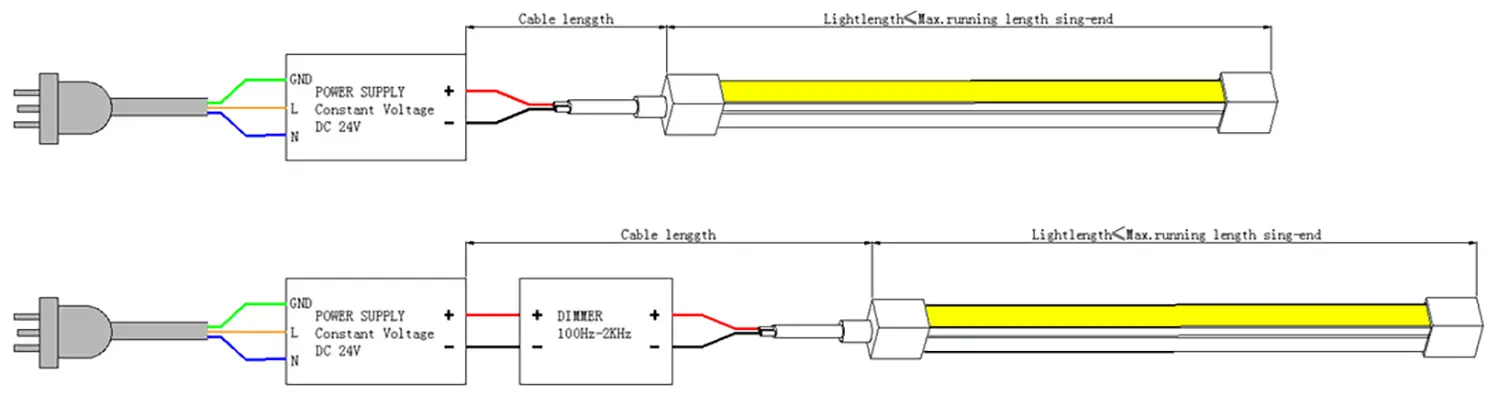

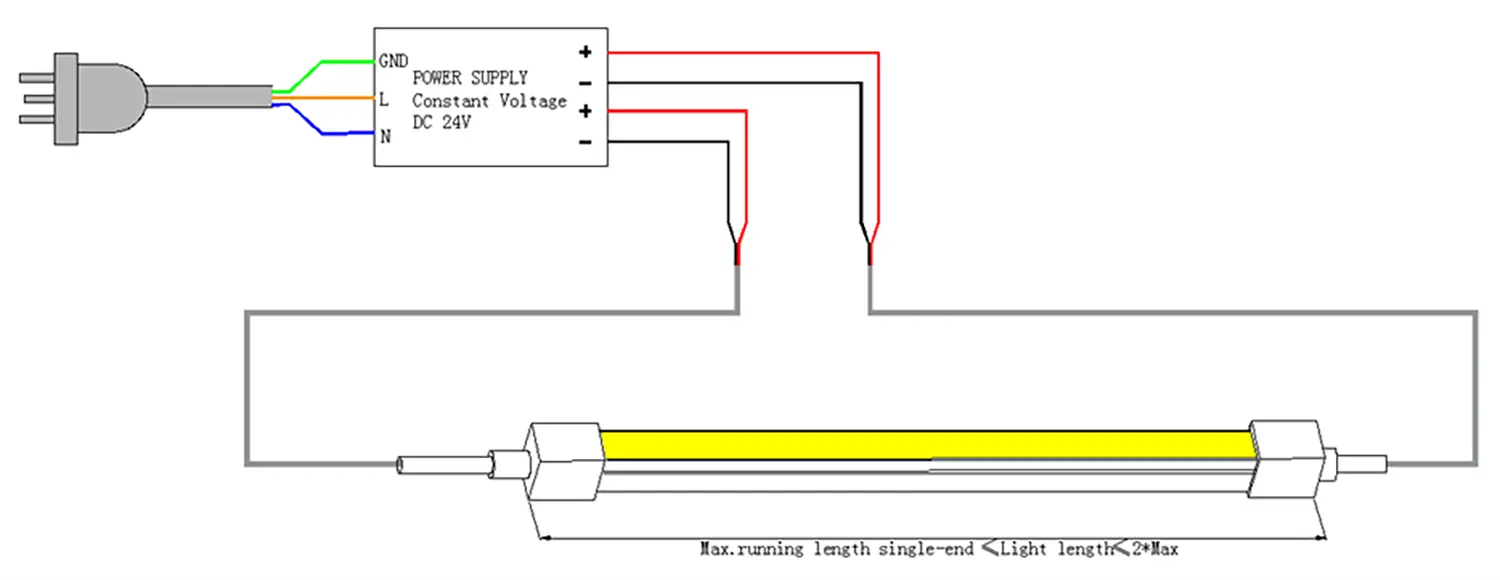

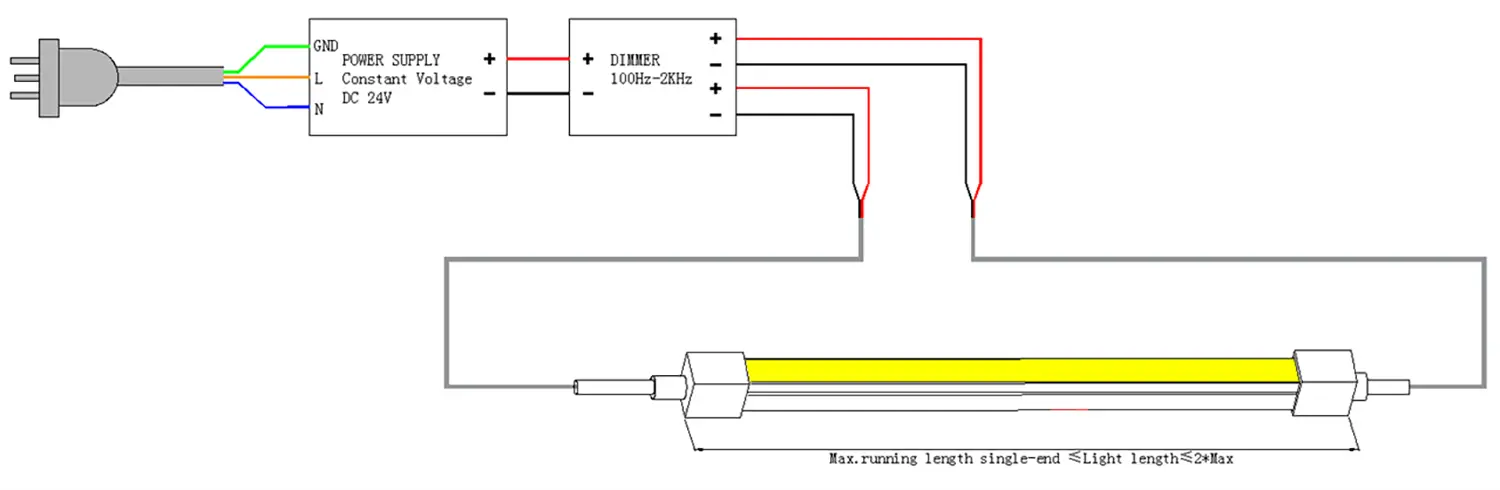

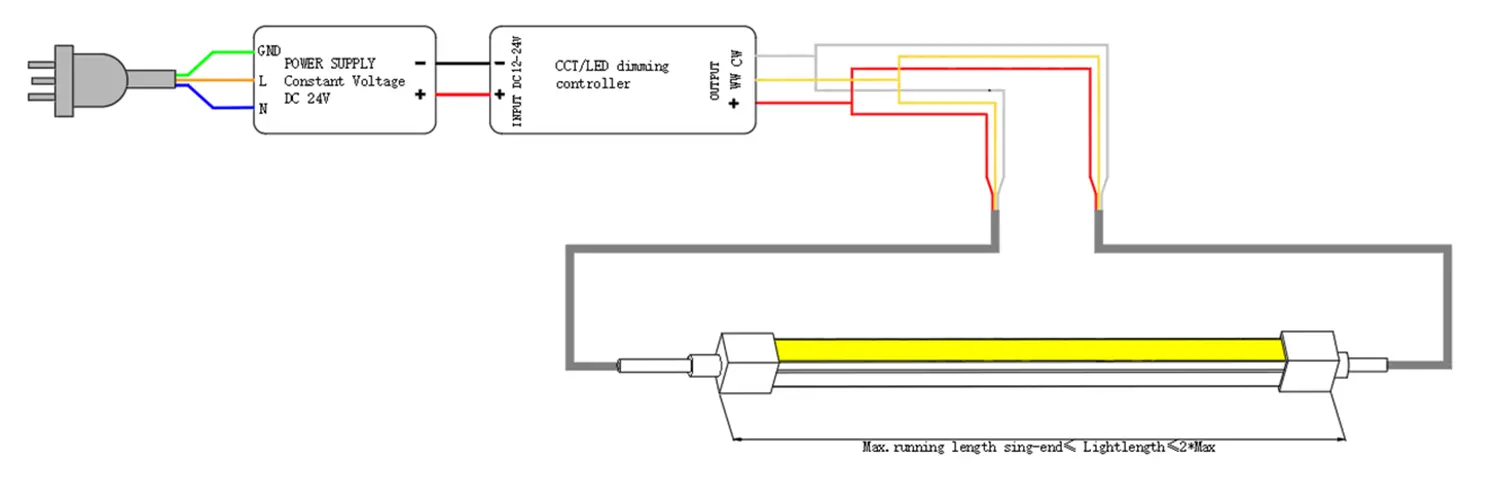

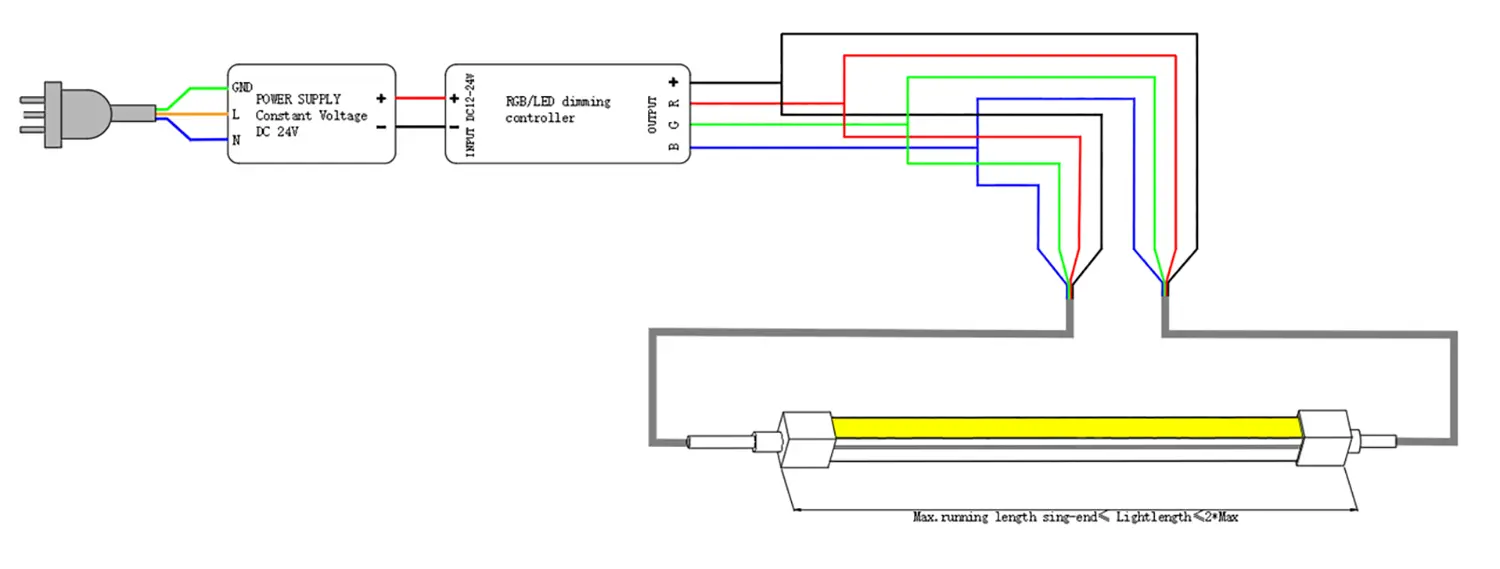

| Napięcie: | DC24V |

| Moc: | 10W/M |

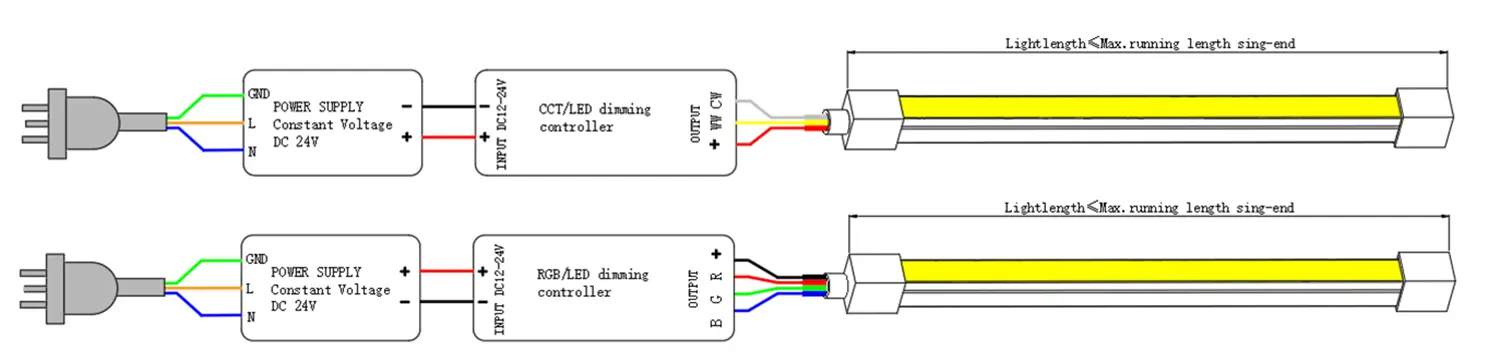

| CCT: | 2100K, 2700K, 3000K, 3500K, 4000K, 5000K, 2700K+5000K, RGB |

| CRI: | ≥90Ra |

| Kąt: | 110° |

| Stawka IP: | IP67 |