Choosing between PU and silicone LED neon flex lights can be challenging. Both materials have distinct advantages, but understanding their differences will help you make the right choice. Here’s a comprehensive guide to help you decide.

PU LED neon flex lights are durable and cost-effective, while silicone ones offer superior flexibility and heat resistance. Choose PU for budget-friendly projects and silicone for high-performance applications.

Keep reading to discover the benefits, drawbacks, and ideal applications of PU and silicone LED neon flex lights.

What Are PU LED Neon Flex Lights?

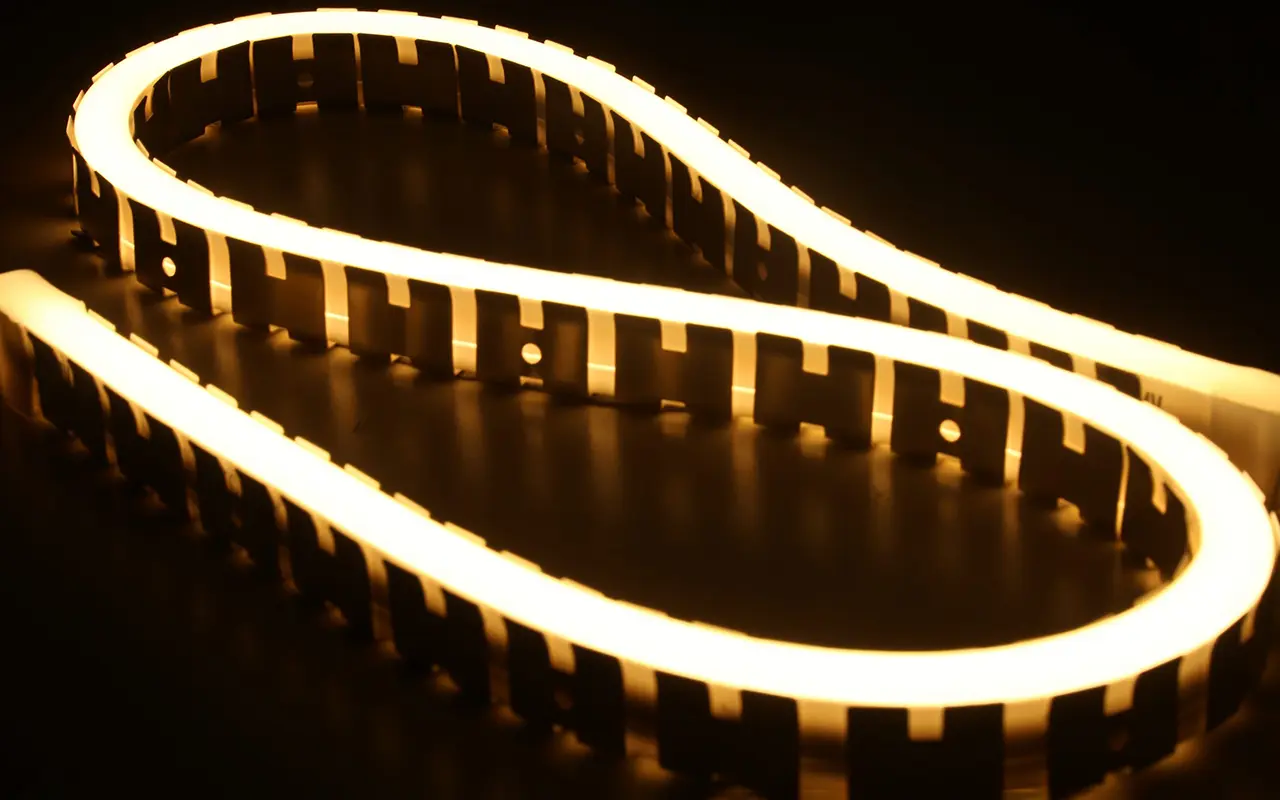

Polyurethane (PU) LED neon flex lights are popular for their durability and affordability. PU material is known for its robustness, making it an excellent choice for outdoor and industrial applications. These lights are resistant to impact, water, and UV rays, ensuring longevity even in harsh environments. Additionally, PU LED neon flex lights are easy to install and maintain, providing a cost-effective solution for various lighting needs.

PU LED neon flex lights are designed to mimic the look of traditional glass neon lights but with added flexibility and durability. The core of the light strip is composed of LEDs, which are known for their energy efficiency and long lifespan. These LEDs are encased in a flexible PU material, which protects the lights from physical damage and environmental factors. This combination makes PU LED neon flex lights suitable for a wide range of applications, from decorative accents in homes to functional lighting in commercial and industrial settings.

One of the standout features of PU LED neon flex lights is their ability to provide uniform, consistent lighting. The PU encasing diffuses the light evenly, eliminating hot spots and creating a smooth, continuous glow. This makes them ideal for applications where aesthetic appeal is important, such as signage, architectural lighting, and artistic installations.

Advantages of PU LED Neon Flex Lights

Durability

PU lights are highly resistant to wear and tear, making them ideal for heavy-duty applications. Their robust nature ensures they can withstand rough handling and harsh environmental conditions, making them perfect for outdoor and industrial use. PU LED neon flex lights are built to last, withstanding impacts and vibrations that would damage more fragile lighting options. This durability translates to lower maintenance costs and longer replacement cycles, providing significant cost savings over time.

Cost-Effectiveness

PU is generally cheaper than silicone, offering a budget-friendly option without compromising on performance. This makes PU LED neon flex lights an excellent choice for projects where cost is a significant consideration. Despite their lower cost, PU LED neon flex lights do not sacrifice quality, providing reliable and efficient lighting at a fraction of the price of more expensive materials. This affordability makes them accessible for a wide range of applications, from small DIY projects to large-scale commercial installations.

Water and UV Resistance

These lights are perfect for outdoor use as they withstand harsh weather conditions and prolonged sun exposure. PU’s resistance to water and UV rays ensures the lights remain functional and visually appealing over time. This makes them suitable for environments such as gardens, patios, and outdoor commercial spaces, where they can enhance the ambiance without requiring frequent replacements or repairs. The water and UV resistance also make PU LED neon flex lights a reliable choice for areas with unpredictable weather patterns.

Ease of Installation

PU lights are lightweight and flexible, simplifying the installation process. Their ease of handling makes them suitable for various applications, from home decor to large-scale industrial projects. The flexibility of PU LED neon flex lights allows them to be bent and shaped to fit a wide range of designs, making installation quick and easy. Whether you’re outlining architectural features, creating custom signage, or adding decorative lighting to a space, PU LED neon flex lights can be installed with minimal effort and tools. Their user-friendly nature makes them a popular choice for both professional installers and DIY enthusiasts.

Drawbacks of PU LED Neon Flex Lights

Flexibility Limitations

PU is less flexible than silicone, which may limit its use in intricate designs or tight spaces. This reduced flexibility can be a drawback for projects requiring detailed and complex lighting arrangements. While PU LED neon flex lights can still be shaped and bent to some extent, they may not achieve the same level of precision and adaptability as silicone lights. This limitation can be a consideration for projects that require tight bends, intricate patterns, or complex installations.

Heat Resistance

PU does not handle high temperatures as well as silicone, potentially reducing its lifespan in hot environments. In areas with extreme temperatures, PU lights may not perform as well over time. This heat sensitivity can lead to reduced efficiency and a shorter lifespan in hot climates or applications where the lights are exposed to high levels of heat. For projects located in hot regions or involving high-temperature environments, silicone LED neon flex lights may be a more suitable option.

Color Stability

Over time, PU can yellow when exposed to UV light, affecting the aesthetic appeal of the lighting. This color instability can be a significant drawback for applications where long-term visual consistency is essential. While the initial appearance of PU LED neon flex lights is vibrant and appealing, prolonged exposure to UV rays can cause discoloration, impacting the overall look and feel of the lighting. This is particularly important for applications such as signage and decorative lighting, where maintaining a consistent and attractive appearance is crucial.

By understanding these advantages and drawbacks, you can make an informed decision about whether PU LED neon flex lights are the right choice for your project. If durability, cost-effectiveness, and ease of installation are your top priorities, PU lights may be the perfect solution. However, if flexibility, heat resistance, and long-term color stability are more critical for your needs, you may want to consider other options such as silicone LED neon flex lights.

What Are Silicone LED Neon Flex Lights?

Silicone LED neon flex lights are renowned for their exceptional flexibility and high-temperature resistance. Silicone is a versatile material that maintains its properties across a wide temperature range, making it suitable for both indoor and outdoor applications. These lights are ideal for detailed designs and installations requiring frequent bending and shaping. Silicone’s inherent resistance to UV light ensures long-term color stability and aesthetic consistency.

Silicone LED neon flex lights are designed to provide a modern alternative to traditional neon lighting, offering the same bright, eye-catching glow without fragility and high energy consumption. The LEDs are embedded within a flexible silicone casing, which protects the lights from external damage and environmental factors. This flexibility allows the lights to be bent and shaped into almost any configuration, making them perfect for intricate designs and creative projects.

The use of silicone in these lights also provides significant advantages in terms of thermal management. Silicone can withstand a wide range of temperatures without degrading, which means the lights can be used in both extremely hot and cold environments. This makes them suitable for a variety of applications, from indoor decorative lighting to outdoor commercial installations in challenging climates.

Advantages of Silicone LED Neon Flex Lights

Superior Flexibility

Silicone’s flexibility allows for intricate designs and tight bends, perfect for creative lighting solutions. This makes silicone LED neon flex lights ideal for applications requiring detailed and complex arrangements. Whether you’re outlining architectural features, creating custom signage, or designing artistic lighting installations, silicone lights can be easily manipulated to achieve the desired effect. This superior flexibility also means the lights can be installed in spaces where other types of lighting might not fit, providing greater versatility in design and application.

Heat Resistance

Silicone can withstand high temperatures, making it ideal for environments with significant heat exposure. This high-temperature tolerance ensures the lights maintain their performance and longevity in various conditions. Unlike other materials that may degrade or fail when exposed to high temperatures, silicone maintains its integrity, ensuring consistent performance and extending the lifespan of the lights. This makes silicone LED neon flex lights a reliable choice for applications in hot climates or near heat-generating equipment.

UV Stability

Silicone resists yellowing and degradation from UV light, ensuring the lights maintain their appearance over time. This long-term color stability is a significant advantage for outdoor and decorative applications. Prolonged exposure to sunlight can cause other materials to discolor and degrade, but silicone remains unaffected, preserving the vibrant colors and clean appearance of the lights. This makes silicone LED neon flex lights ideal for outdoor signage, architectural lighting, and other applications where long-term visual appeal is important.

Durability

Silicone is also highly durable, offering long-lasting performance in various applications. Its robust nature ensures the lights can withstand harsh environmental conditions and frequent handling. Silicone LED neon flex lights are resistant to water, dust, and other contaminants, making them suitable for both indoor and outdoor use. This durability translates to lower maintenance costs and fewer replacements, providing significant cost savings over time. Additionally, the lights are impact-resistant, ensuring they can endure physical stresses without damage.

Drawbacks of Silicone LED Neon Flex Lights

Higher Cost

Silicone lights are generally more expensive than PU lights, which may be a consideration for budget-conscious projects. The higher cost can be a significant factor for large-scale installations where budget constraints are a priority. While silicone LED neon flex lights offer many advantages, the initial investment can be higher compared to other materials. However, this cost can be offset by the longer lifespan and lower maintenance requirements of silicone lights, making them a cost-effective option in the long run for projects where durability and performance are crucial.

Weight

Silicone lights can be heavier than PU lights, potentially complicating certain installations. This additional weight may require more robust support structures and careful planning during installation. The increased weight can make the lights more challenging to install, especially in applications where lightweight materials are preferred. However, with proper planning and the right support structures, silicone LED neon flex lights can still be effectively used in a wide range of applications.

Installation Complexity

Due to their increased flexibility, silicone lights may require more careful handling during installation to avoid damage. The delicate nature of silicone can complicate the installation process, requiring more attention to detail and precision. Installers need to be mindful of not over-bending or overstretching the lights, which could damage the silicone casing and the LEDs inside. While this added complexity can increase the installation time and effort, the end result is a high-quality, durable lighting solution that offers exceptional performance and aesthetic appeal.

Which One Should You Choose?

Choosing between PU and silicone LED neon flex lights hinges on your specific needs, the environment of the application, and your budget. Both materials offer unique benefits, and the best choice will depend on the particular requirements of your project.

Cost-Effectiveness vs. Performance

PU LED neon flex lights are an excellent choice if cost-effectiveness is a primary concern. Their lower price point makes them an attractive option for budget-conscious projects without sacrificing too much on performance. These lights are durable and offer good resistance to water and UV rays, making them suitable for outdoor and industrial use. If your project involves large-scale installations or requires a significant amount of lighting, PU LED neon flex lights can provide a cost-effective solution that meets your needs without breaking the bank.

On the other hand, silicone LED neon flex lights are better suited for applications that demand superior performance and flexibility. Although they come at a higher cost, silicone lights offer unmatched flexibility, heat resistance, and long-term color stability. This makes them ideal for detailed designs, creative installations, and environments with extreme temperatures. If your project requires intricate lighting arrangements, frequent bending, or is located in a hot climate, the investment in silicone LED neon flex lights will pay off in terms of longevity and performance.

Environmental Considerations

The environment in which the lights will be installed plays a crucial role in determining the best material. PU LED neon flex lights are highly resistant to harsh weather conditions, making them a reliable choice for outdoor applications. Their robust nature ensures they can withstand rough handling and environmental factors such as rain, wind, and UV exposure. However, their performance may degrade in extremely high temperatures, so they are less suitable for very hot climates.

Silicone LED neon flex lights, with their superior heat resistance and UV stability, are ideal for environments with fluctuating temperatures or prolonged sun exposure. They maintain their appearance and performance over time, even in extreme conditions. This makes silicone lights a better option for outdoor installations in hot climates, coastal areas, or locations with high UV exposure. Additionally, their excellent weather resistance ensures they remain functional and visually appealing for longer periods, reducing the need for frequent replacements.

Application-Specific Needs

Consider the specific requirements of your application when choosing between PU and silicone LED neon flex lights. PU lights are perfect for projects that prioritize durability and cost-efficiency, such as industrial lighting, large outdoor installations, and basic decorative purposes. Their ease of installation and maintenance further enhance their suitability for these applications.

Silicone lights are preferred for projects requiring detailed and complex lighting arrangements, such as custom signage, artistic installations, and architectural lighting. Their superior flexibility allows for precise shaping and bending, enabling intricate designs that would be challenging with PU lights. Additionally, silicone lights’ long-term color stability and high-temperature resistance make them ideal for high-performance applications where visual consistency and durability are paramount.

Budget Considerations

Your budget is a critical factor in making the final decision. PU LED neon flex lights provide an affordable option without significantly compromising on quality. They are an excellent choice for projects with limited budgets, offering reliable performance at a lower cost.

If your budget allows for a higher initial investment, silicone LED neon flex lights offer enhanced features that justify the additional expense. The longer lifespan, reduced maintenance needs, and superior performance of silicone lights offset the higher cost. Investing in silicone lights can result in long-term savings and better overall results, especially for projects where flexibility, heat resistance, and aesthetic appeal are essential.

By carefully considering the environment, application, and budget, you can make an informed decision between PU and silicone LED neon flex lights. Each material has its strengths and is best suited for specific scenarios, ensuring you achieve the desired outcome for your lighting project.

Additional Tips for Choosing LED Neon Flex Lights

Consider Your Project’s Requirements

Before making a decision, consider the specific requirements of your project. Determine the environmental conditions, desired design complexity, and budget constraints to choose the most suitable material for your LED neon flex lights.

Evaluate the Installation Environment

Assess the installation environment to ensure the chosen material can withstand the conditions. For example, outdoor installations may require materials with high UV resistance and water resistance, while indoor installations may prioritize flexibility and aesthetic appeal.

Compare Product Specifications

Review the product specifications of different LED neon flex lights to compare their performance characteristics. Look for details on durability, flexibility, heat resistance, and UV stability to make an informed choice.

Consult with Experts

If you’re unsure about which material to choose, consult with lighting experts or manufacturers. They can provide valuable insights and recommendations based on your project’s requirements and help you select the best LED neon flex lights for your needs.

Conclusion

Both PU and silicone LED neon flex lights have their unique advantages and drawbacks. PU lights are durable and cost-effective, making them suitable for budget-friendly and robust applications. Silicone lights, on the other hand, offer superior flexibility, heat resistance, and long-term color stability, making them ideal for high-performance and detailed lighting solutions. By understanding the strengths and limitations of each material, you can make an informed decision that best suits your needs and ensures the success of your lighting project.

Choosing between PU and silicone LED neon flex lights depends on your needs, environment, and budget. Each material offers unique advantages for different applications. Unitop, a leading manufacturer of LED strip lights and LED neon flex in China, is committed to quality and innovation. For further questions or specific requirements, contact us. Let Unitop help you illuminate your spaces with our top-tier LED products.

Tom is now the Sales Manager of Unitop (China) Co., Limited. He has been in the LED Lighting industry ever since 2005. He is an expert in sales & marketing, and factory management. He likes bodybuilding, and he is also a crazy Apple Fan! He is a hard-working guy and loves to learn and try new things.

Email: tom@unitopledstrip.com WhatsApp: +86-18680307140

Leave a Reply

Want to join the discussion?Feel free to contribute!